A Lightweight and Flexible Solar Panel — The Future of Solar Energy?

2019/08/07 Toshiba Clip Team

What do you think when you hear the term “solar energy”? Most of you will think of wide-open spaces, packed to the edges with giant solar panels, and you’d be right—for now. We’re here to tell you that the next generation of solar energy may look very, very different.

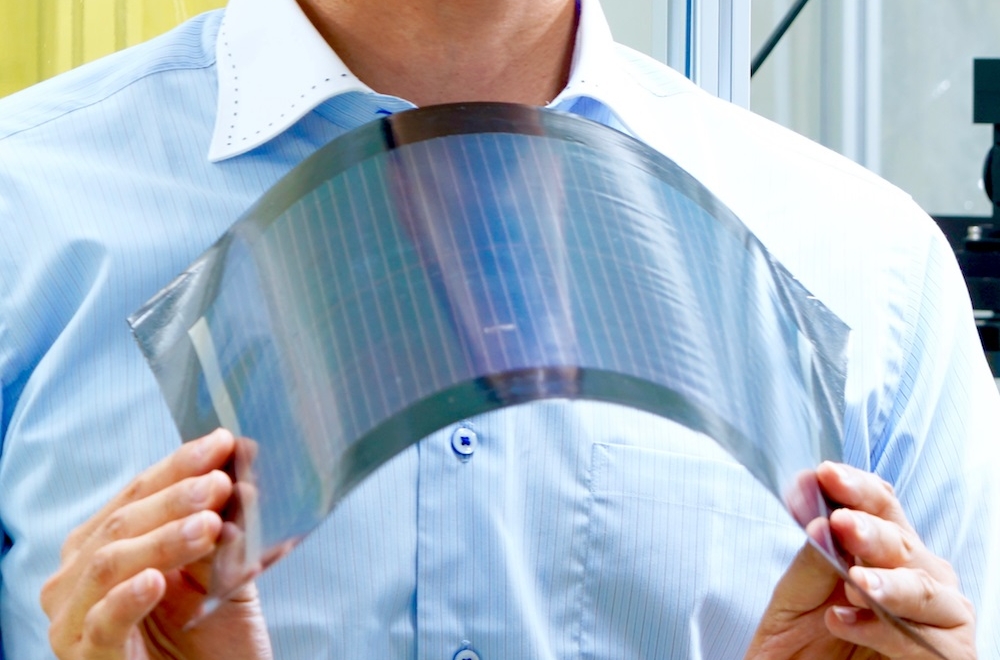

The solar panels that currently dominate the market are comprised of crystalline silicon solar cells. However, their shape and weight has limited their placement to flat, wide-open spaces, and the roofs of very sturdy buildings. Here’s where the film-based perovskite* solar cell module comes in. It’s a new kind of solar cell currently under development by Toshiba and the New Energy and Industrial Technology Development Organization (NEDO)—one that is lightweight and even flexible. The question is, how will this new solar cell change the solar energy landscape?

*A type of crystalline structure. Refers to the crystalline structure of the oxide known as perovskite.

A light and flexible solar cell

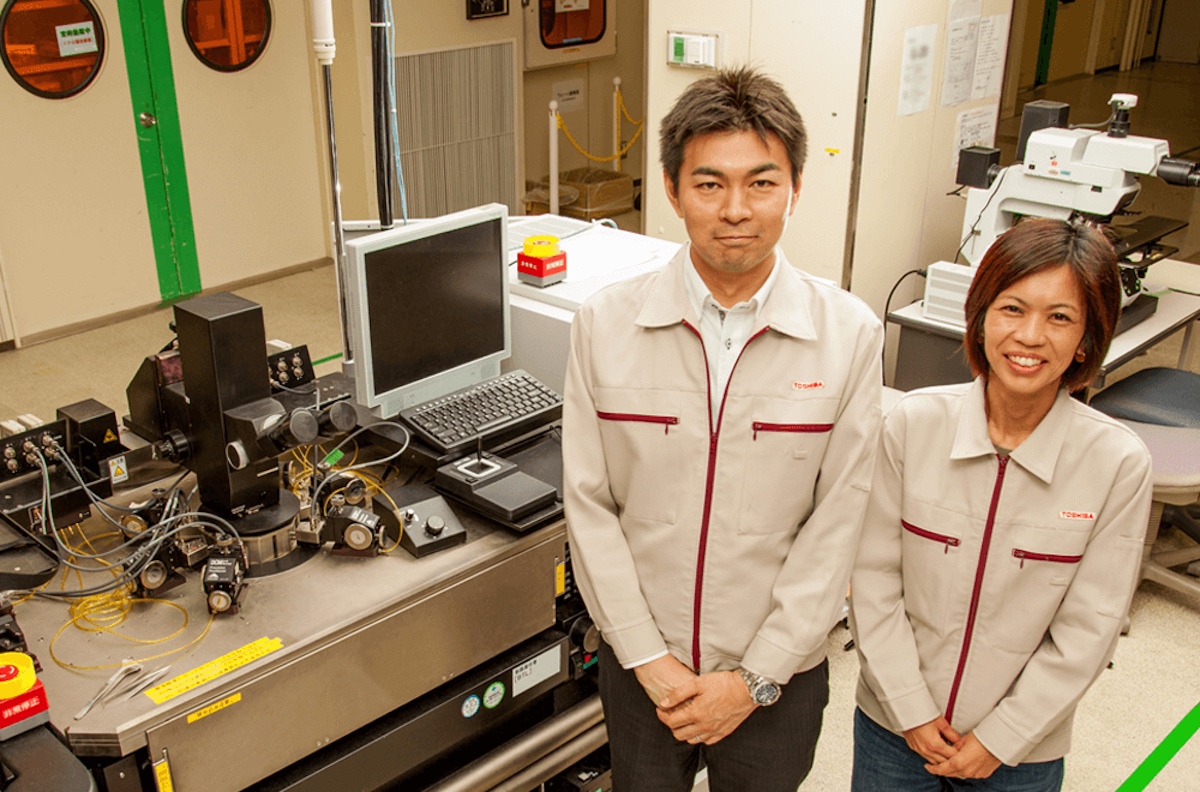

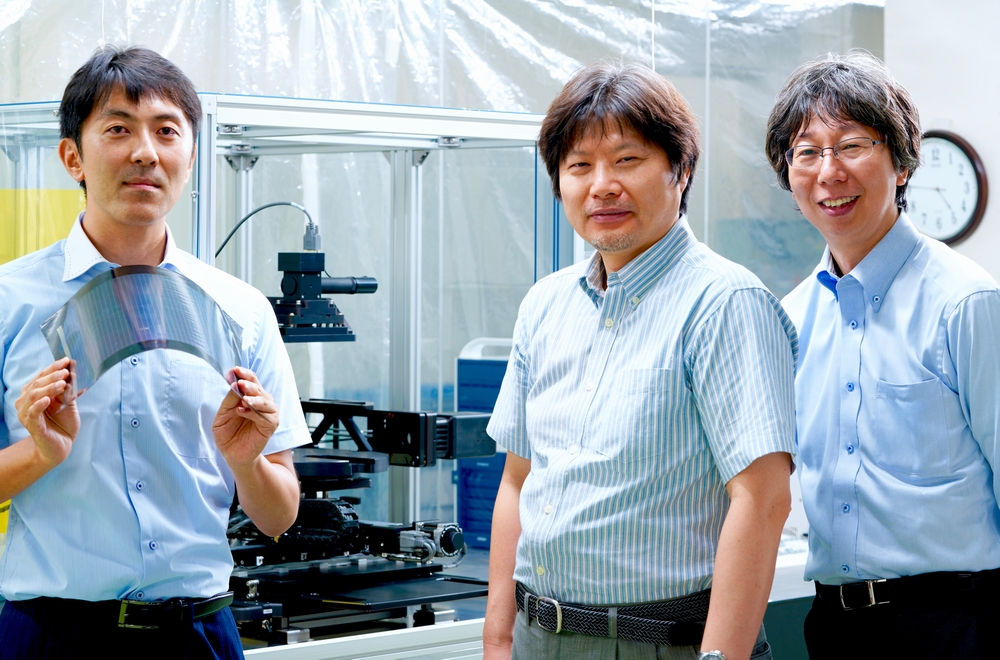

Perovskite solar cells are so lightweight and flexible because, unlike rigid crystalline silicon solar cells, they are made in a film-based structure. We asked researchers Koji Mizuguchi, Kenji Todori, and Akio Amano at the Transducer Technology Laboratory, Toshiba Corporate Research & Development Center, about their thoughts on this new technology.

From left to right: Akio Amano, Kenji Todori, and Koji Mizuguchi from the Corporate Research & Development Center, Toshiba Corporation

“The greatest advantage of film-based perovskite solar cells is that they can be installed in locations that would be impossible for the crystalline silicon solar cells,” says Todori. “They can be installed in all kinds of places—on the walls of buildings and apartments, roofs of large vehicles, and tents—even in urban areas, where large spaces can be difficult to come by. This way, we’re hoping to establish a new market separate from the existing market for solar cells.”

In perovskite solar cells, the perovskite crystals on the substrate absorb light and generate energy. Since the material that goes on top of the substrate can be literally painted on, the substrate can be made with low-cost material, like film. This film substrate is also why this type of solar cell is so lightweight and flexible. They’re made from cheap materials, and can be manufactured cheaply as well using printing technologies that wrap the film up into rolls.

Laboratory leader Mizuguchi explains more: “That’s not the only thing that’s exciting about these solar cells. Perovskite solar cells also have the potential to reach an energy conversion efficiency equivalent to that of the current crystalline silicon type. Energy conversion efficiency refers to how much energy can be generated from a set amount of sunlight. Our target, in our joint research with NEDO, is 15% energy conversion efficiency, which is equivalent to the efficiency of the majority of crystalline silicon solar cells in use today.”

It is clear that there are many advantages to perovskite solar cells. The team did face an issue, however, specific to this new technology.

“Perovskite, once coated onto film, crystallizes very quickly, and it’s difficult to create an even layer of it across a large area,” Amano says. “The challenge was creating a solar cell that had as much surface area as possible, while still maintaining a high level of energy conversion efficiency.”

There are two critical success factors—as large a surface area as possible, and as high an energy conversion efficiency as possible. In the end, it was the knowledge that Toshiba had accrued over more than ten years of relevant research that provided the technological breakthrough they needed to achieve both these requirements.

Behind-the-scenes of a record-breaking achievement

In June 2018, Toshiba and NEDO—in a joint development project—managed to produce a film-based perovskite solar cell with the largest surface area and highest energy conversion efficiency in the world.

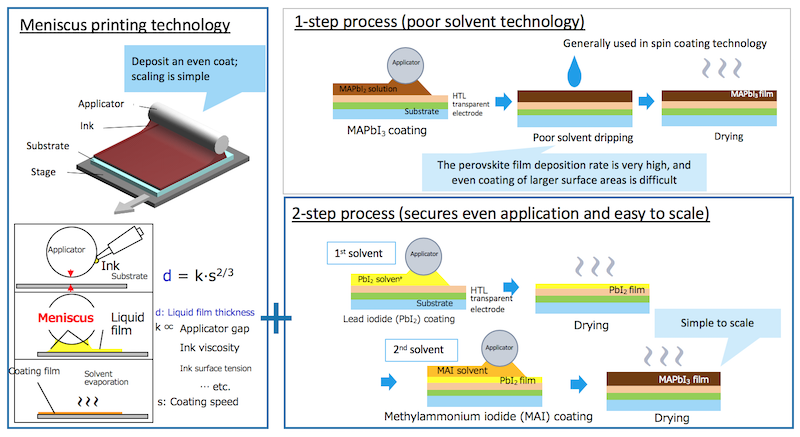

This accomplishment boiled down to the meniscus printing technology that Toshiba chose to use in the manufacturing process.

Toshiba had developed this printing technology in 2008, during its research on organic electroluminescence, and had conducted further R&D on it as a potential technology for organic thin-film solar cells. The knowledge then made its way, finally, into the manufacturing of perovskite solar cells, and proved itself very useful in this capacity.

Amano explains: “Try to create a layer of perovskite in a single motion, and the perovskite crystallizes so fast it ends up not being very good quality. So we separated the ingredients in the perovskite formation process—into a lead iodide (PbI₂) and a methylammonium hydroiodide (MAI) solution—and coat the substrate first with the PbI₂ solution, followed by the MAI solution. Through this, we were able to adjust the rate of crystal growth on the substrate, and create an even layer of perovskite. There were other tweaks we made as well, such as the composition of the ink, and the conditions when the layer dries. Through all of this, we succeeded in creating more uniform layers of crystals, uniform across a large surface area.”

Meniscus printing technology

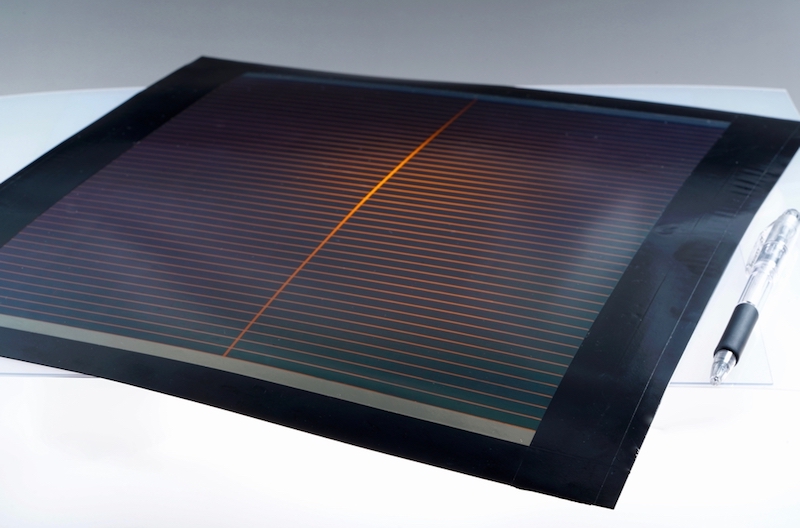

The film-based perovskite solar cell module manufactured through these methods is 703cm²—much closer to the 900cm², size considered the target for practical use—and has an 11.7% energy-conversion efficiency, which is close to the 15% target. Even better, this efficiency is expected to go up to 20% or even higher with further development. And though its practical use was expected to begin around 2025, reports say that it could happen even earlier.

The film-based perovskite solar cell developed by Toshiba and NEDO

“It’s not like the surface area issue was the only issue we had with these solar cells,” notes Mizuguchi. “For instance, the film structure makes it difficult to make these durable. However, unlike crystalline silicon solar cells, which are installed on the roofs of buildings and are meant to last 20-30 years, these can be replaced fairly easily for things such as renovations, and we may not need to make them last a whole 20 years.”

Future prospects: making friends with farming

One area that may greatly benefit from perovskite solar cells is farming. This is because this new technology allows farms to use solar cells for both power generation and farming.

As Todori explains: “You can control the transparency of perovskite solar cells by how thin you make the layer of perovskite. As such, you can use it as covering for greenhouses, and they’ll let in the amount of light needed for the crops, while also generating the energy needed to power the farming process. The experiments are already done in Japan to see what the perfect ratio is for this kind of use.”

This same characteristic would also allow these solar cell modules to be installed on the windows of office buildings and high-rise apartment buildings. This would mean solar energy on a massive, urban scale.

Perovskite has the potential to revolutionize the energy landscape, and bring immediate benefits to industry and society.

Perovskite solar cell experiment equipment

From left to right: Akio Amano, Kenji Todori, and Laboratory leader Koji Mizuguchi

![]()