Designing the future of energy – converting CO₂ from the villain to a new hero -The Start of the “Carbon Recycling” Era

2022/09/30 Toshiba Clip Team

- The time has come for carbon recycling. How CO₂ electrolysis technology can turn CO₂ into fuel and other resources.

- A new hero in the airline industry’s battle against CO₂ emissions

- Counting down to the world’s first commercial flight powered by sustainable aviation fuel (SAF)!

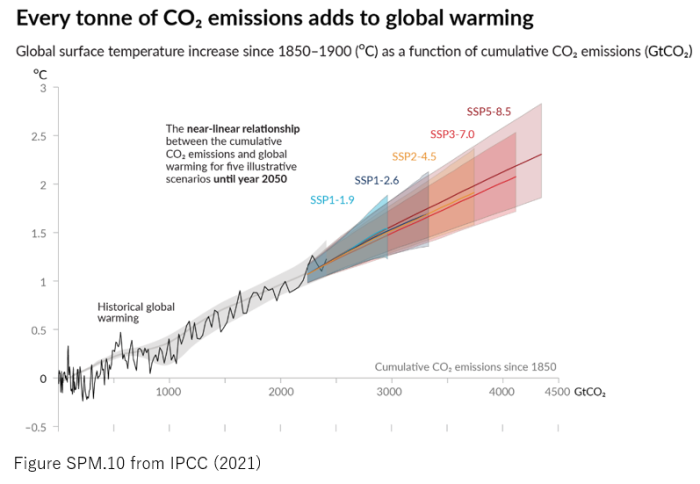

Super-typhoons, record rainfall… It seems, in recent years, that the world has been thrown off-balance. News about climate change has become a permanent fixture. Extreme weather—floods, droughts, record temperatures—are occurring with ever increasing frequency, and show no sign of abating. Words such as “CO₂,” “decarbonization,” and “global warming,” have become a part of our everyday language. So what’s causing all of this?

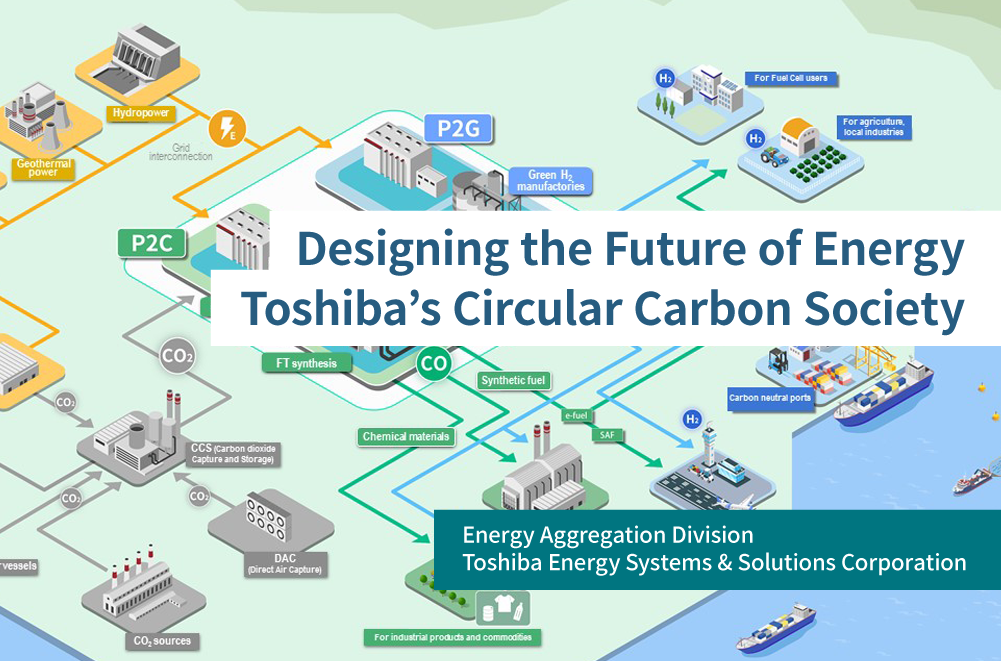

According to the IPCC*, an organization of climate change experts, CO₂ emissions and the global temperature have moved, historically, almost in tandem—as you can see in the following graph. Negative effects, like the sort of climate change described above, occur when this global temperature rises past a certain point. And if the cycle goes as “CO₂ emissions => Global warming => Climate change,” it stands to reason that we must tackle the source: CO₂ emissions. While most measures would classify CO2 as the “villain” in this scenario, Toshiba has taken an innovative and pioneering approach, developing a business that recycles CO₂ and converts it into fuel and other resources, which can facilitate collaboration with a wide range of companies. To find out more about this business, we spoke to the members who have been with this project since its inception.

*Intergovernmental Panel on Climate Change: International institution comprised of experts that collects and consolidates scientific research on climate change

Global warming advances as CO₂ emissions increase

The CO₂ Electrolysis Unit and Designing an Energy Paradigm Shift

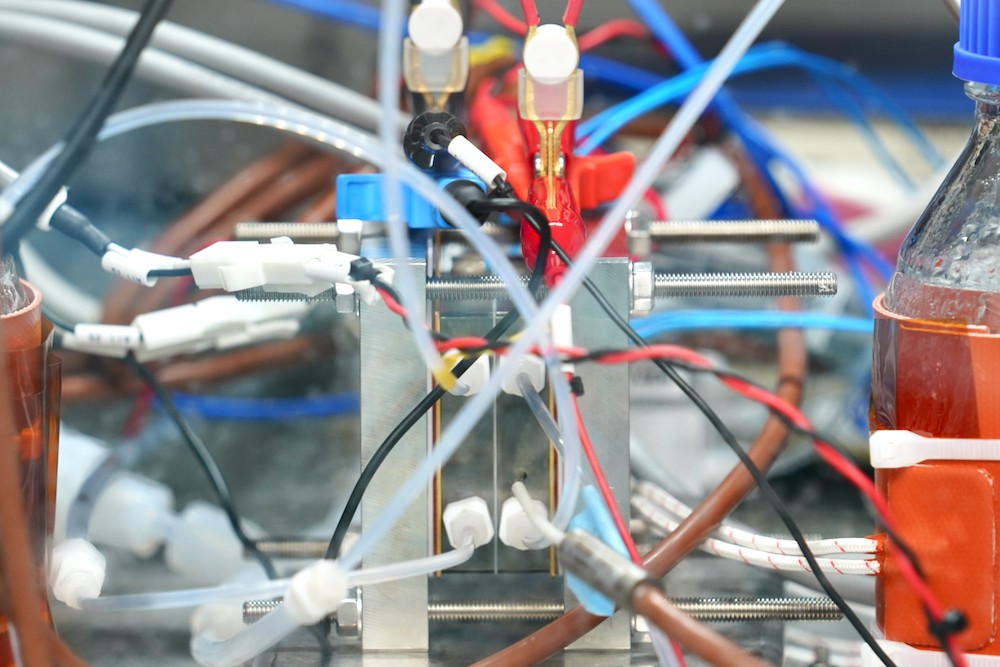

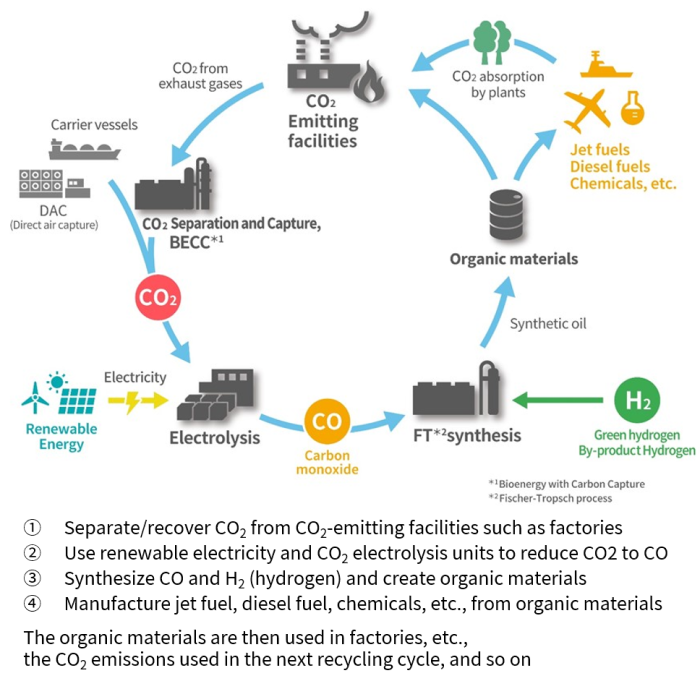

A “carbon recycling society.” After many years of on-going research, Toshiba is currently engaged in commercial development activities to help make this a reality. The focus is on the P2C (Power to Chemicals) cycle described above, in which CO₂ is converted into a resource, with research and development underway to put the compact and highly-throughput CO₂ electrolysis units into practical use. These units use renewable energy to electrolyze CO₂ and produce CO (carbon monoxide). Combine CO with hydrogen, and you can produce things such as e-fuel and plastics—in other words, resources. The crux of the P2C cycle are the CO₂ electrolysis units that generate CO through renewable energy.

Toshiba is not alone in this endeavor, working with a number of partner companies to explore potential new-generation energy businesses that could make use of CO₂-produced resources such as jet fuel. In doing so, Toshiba is accelerating the commercialization of P2C technologies. As discussed before, the CO₂ electrolysis unit is the key that will unlock the commercialization of P2C and the process of turning CO₂ into a resource. And the development of this unit warrants its own story. Toshiba’s development of fuel cell technologies, has been a critical in developing this unit. But how exactly? We spoke to Hiroyuki Ota of Toshiba Energy Systems & Solutions Corporation to find out.

Hiroyuki Ota, Expert, Hydrogen Energy Engineering Department, Energy Aggregation Division, Toshiba Energy Systems & Solutions Corporation

“The R&D team at Toshiba had been able to develop a CO₂ electrolysis unit with one of the best CO2 conversion efficiencies in the world. But this was only at the laboratory level (several thousand grams class), and they hadn’t been able to get it to the level of practical use (ton class). Another difficulty they faced was the amount of electricity needed to electrolyze CO₂, which meant that efforts to move the unit towards practical use would require it to be very large.

This was when we became convinced that the lamination and manufacturing technologies we use at Toshiba Energy Systems & Solutions for hydrogen fuel cells could also be applied here. In concrete terms, this would mean enlarging the surface area of the cells used to electrolyze the CO₂, stacking them into numerous layers, and boosting the processing power that way. This is the same cell structure as for fuel cells, which meant we could potentially use the same manufacturing lines and technologies as for our hydrogen fuel cells. If we could do that, we could commercialize the units at an early stage and reduce manufacturing costs.

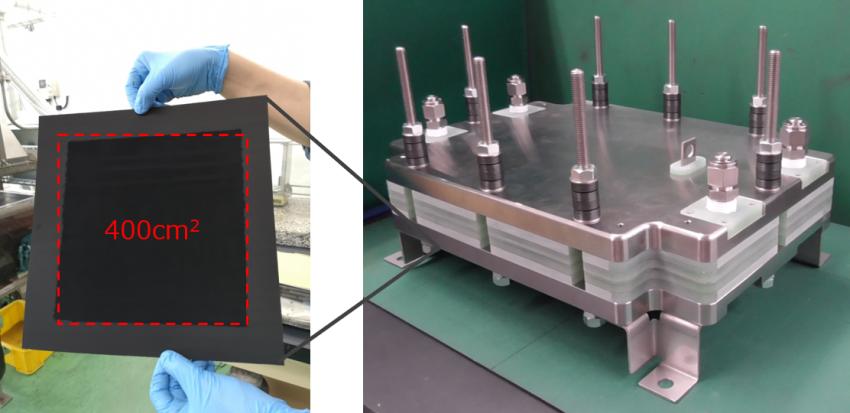

The results were incredible. By applying the manufacturing technology for our hydrogen fuel cells, we were able to create a cell with 25 times the surface area of the cell made by R&D. When this is put to practical use, a unit with a surface area about the size of a basketball court should be able to process about 100,000 tons of CO₂ a year,” says Ota.

Exterior of the CO2 electrolysis unit

The Clever Use of Renewable Energy in Recycling CO₂

It was the coordination between the commercial team, Ota, and R&D team that made this giant leap in processing power possible. And of course, the similarity in structure between the CO₂ electrolysis unit and the laminated structure of Toshiba’s existing fuel cell product meant that the unit could be manufactured on the same production lines. At this point, Ota was confident that the unit could be commercialized, and came up with the following conceptual diagram of carbon recycling through a P2C business. The sticking points when creating this plan was what product to create through this CO₂ electrolysis technology that would be useful to society, and the difficulty in creating a supply chain for such a product while also developing this technology. While market research revealed that the highest anticipation for this sort of market was for jet fuel, creating a supply chain for such a resource would be a difficult endeavor for the Toshiba Group alone. The next logical step was for Ota to look outside of the company. And so he did, coming up with presentations and business scenarios for potential business partners.

Circular Carbon Society diagram

“During this process of trying to commercialize the unit, we weren’t able to get an internal decision request through, and therefore we had no budget. But as we set about trying to find people to support us, we found people in different companies and departments in the Group—in Toshiba Energy Systems & Solutions, but also in the Corporate Research & Development Center, Toshiba Infrastructure Systems, and Toshiba headquarters staff—who sympathized with our efforts and volunteered to help us.

At this point, the plan was still very much up in the air. But they sympathized with our passion to develop the business, as something that would embody our corporate philosophy: ‘Committed to People, Committed to the Future.’ I was very moved by how motivated they were,” says Ota.

With their support, the project began advancing rapidly. In a little over three months, they developed a presentation, and began to engage with reliable, major companies in areas such as energy, plant engineering, and the chemical industry, and even those who would be the end customers in the cycle—one-on-one, and on an unofficial basis—with proposals for collaboration. This was hard, boots-on-the-ground sort of work, but it earned them favorable responses from many companies. This—the fruit of their careful preparation and ceaseless efforts—gave them the momentum they needed, and in 2020, their internal decision request went through. The P2C commercialization project had begun.

“Superpower Line-Up” Tackles the Issues Surrounding Sustainable Aviation Fuel

The topic that incited the most debate during the conceptualization of the business was what the CO₂ would be used to make. After numerous rounds of market research, they settled on their first target: sustainable aviation fuel (SAF). The reasoning behind this was the International Civil Aviation Organization (ICAO)’s “Carbon Offsetting and Reduction Scheme for International Aviation (CORSIA).” The scheme calls for measures such as the use of alternative fuels, with the goal being to (1) improve fuel efficiency by an average of 2% per year until 2050 and (2) prevent increases in greenhouse gas emissions from 2020 onwards. Partly as a result of this scheme, airline companies had been looking for a way to bring in a steady supply of SAF as soon as possible. Kohei Yoshikawa of All Nippon Airways (ANA), an airline company currently working with Toshiba, spoke to us about the company’s perspective as an SAF user.

Shifting to SAF would be an effective way to move the decarbonization of the airline industry forward

“Decarbonization has become a pressing issue all over in the world, and of course that means for the airline industry as well. The goal of the ANA Group is to reduce our CO₂ emissions from aircrafts to effectively zero by 2050. There are a lot of different methods to reduce emissions, but expanding our use of SAF will be a central part of our efforts. Other countries have already begun manufacturing SAF from biomass, but as of now there’s nowhere near enough supply, and there’s concern that there’ll be a supply shortage for the raw material used to produce it. We as a company have high hopes for Toshiba’s CO₂ conversion technology because the risk of there being supply constraints of the raw material is low, and the level of added value it offers in terms of the environment,” says Yoshikawa.

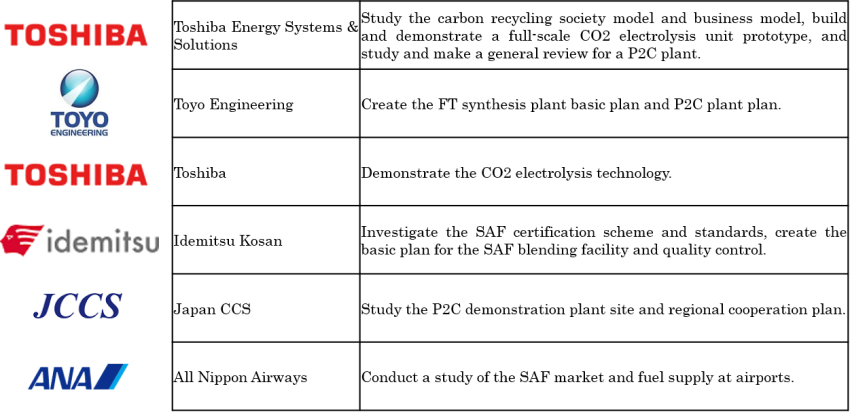

ANA is one of several companies Toshiba is working with in the area of SAF. These partner companies include the likes of Toyo Engineering, with their SAF synthesis technologies; Idemitsu Kosan, with their long-standing experience in the jet fuel market; Japan CCS, with their experience in CO₂ separation and capture—all heavyweights in their respective fields, and slotting perfectly into the supply chain like puzzle pieces. Recognition for this collaborative system and the technologies involved came in August 2021, when Japan’s Ministry of the Environment adopted it as part of its “Project to Promote the Creation of Circular Carbon Society Model Through CO₂ Recycling.” This effort, which had been but a seed, cultivated by supporters that had volunteered for the cause, had bloomed into a national-scale project.

Main roles of demonstration project participating companies:

Directing this project is Hiromichi Odaira, a colleague of Ota’s at Toshiba Energy Systems & Solutions, who spoke to us about his passion for the project.

“The fact that R&D and business development is moving forward at the same time, and there being so many companies involved from all different industries—it’s very exciting. The project members call it a ‘superpower line-up,’ and it really is a massive collaborative project that includes such a wide range of areas from the Toshiba Group itself—different divisions, plants, R&D centers, and more—and six companies from completely different industries. But this also meant we were expecting to struggle when it came to getting the different groups on the same page.”

Surprisingly though, the decision-making process has been relatively smooth for how many people are involved, because we’re all working towards the same goal of carbon recycling. We don’t want it to end as just a verification project. We want to design the future of energy, and create the sort of business model that will be standard in the future. We’re all very much being driven by this sense of purpose,” says Odaira.

Hiromichi Odaira, Manager, Hydrogen Energy Engineering Department, Energy Aggregation Division, Toshiba Energy Systems & Solutions Corporation

Counting Down to the Very First SAF-Powered Commercial Flight

The Toshiba Group’s plans don’t end there. Their vision of the future extends beyond this national project with these business partners, into the potential implementation of this P2C business throughout our global society. Carbon recycling societies are expected to become a real possibility from 2030 onwards. In preparation for this shift, Toshiba plans to conduct further R&D into the CO₂ electrolysis units that will serve as the core technology for this plan, and build a supply chain to help commercialize carbon recycling. We asked Odaira about what he expects for the future.

“Right now, we’re working to make the CO₂ electrolysis unit even larger and increase its processing throughput, and we’re doing that by laminating the electrochemical cells. The research we’ve done so far has been used to develop and verify technologies for packaging the laminated electrochemical cells into a unit, technologies for making the unit itself larger, and more. Things are progressing as planned.

The goal is to complete the prototype for the full-scale CO₂ electrolysis unit by 2023, and commercialize it by 2026. At a certain point in the process, we’ll be laminating electrochemical cells by the hundreds, which may cause difficulties we don’t expect. But what with our collective capability here at Toshiba, and the success we’ve had and the knowledge we’ve accumulated from our fuel cell business, I’m confident we’ll be able to get through it all,” says Odaira.

If you’re like us, the question you may be asking is when we’ll see CO₂-derived SAF will actually be put to practical use. When will we be able to fly on a plane powered by CO₂-derived fuel? Will P2C change the world in other ways? We asked the two project members their thoughts on the matter.

“With how things are right now for the airline industry, we want to get this done as soon as possible. The first commercial flight powered by CO₂-derived jet fuel will be in the sky by the end of the 2020s. That’s the vision that we and our business partners have come up with. This is a long-term project—with about 10 years until the actual implementation of the technology—that also involves a wide range of areas. So I’m ready to make it my lifework,” says Odaira.

“The concept of CO₂ recycling through P2C isn’t limited to SAF, and can be applied to lots of other things, such as other fuels and chemical products manufacturing. The more diverse the range of items we can produce from CO₂—alcohol fuel, plastics, and synthetic fibers, amongst other things—the more we’ll be able to involve different businesses and industries.

The core of this endeavor will be the Toshiba technologies that will design the future of energy, and the goal is to implement carbon recycling through P2C in a way that goes beyond countries, companies, and industries. We want there to be a paradigm shift—one where the ‘villain,’ CO₂, actually turns out to be the new hero we needed all along,” says Ota.

Ota, Odaira, and the rest of the Toshiba team designing the future of energy with P2C

![]()