Procurement Strategies for Uncertain Times: What supply-chain management solved

2022/10/24 Toshiba Clip Team

- “Don’t turn BCP into a manmade disaster.” What does the procurement reform slogan mean?

- Soaring raw materials and labor costs, FX fluctuations... sustainable procurement is a must.

- Aiming for supply-chain resilience and carbon neutrality.

This is a time of uncertainty, the future difficult to predict. Social changes triggered by the pandemic have exposed vulnerabilities and problems caused by obsolete practices, and businesses are being forced to make major changes. One area where this is true is procurement, where logistics have stagnated, and there are shortages of labor and raw materials.

For instance, as COVID-19 spread, it became difficult to obtain masks. Masks are made of a non-woven material that blocks droplets, and a plastic part that shapes to fit the nose. Both are made of polypropylene, a derivative of crude oil. Naturally enough, if the oil supply is disrupted and chemical companies cannot meet sudden enormous demand to make polypropylene, masks will not be manufactured, and we will not be able to get our hands on them.

As all this happens, Toshiba has already been working on procurement reform for more than 10 years. The result is the Meister SRM™, a strategic procurement solution for procurement and purchasing departments in manufacturing industries. How will Toshiba continue to advance procurement reforms, and what will it aim to achieve in the future? How will Meister SRM™ support the evolution of corporate procurement? We asked two key people working on the reform project.

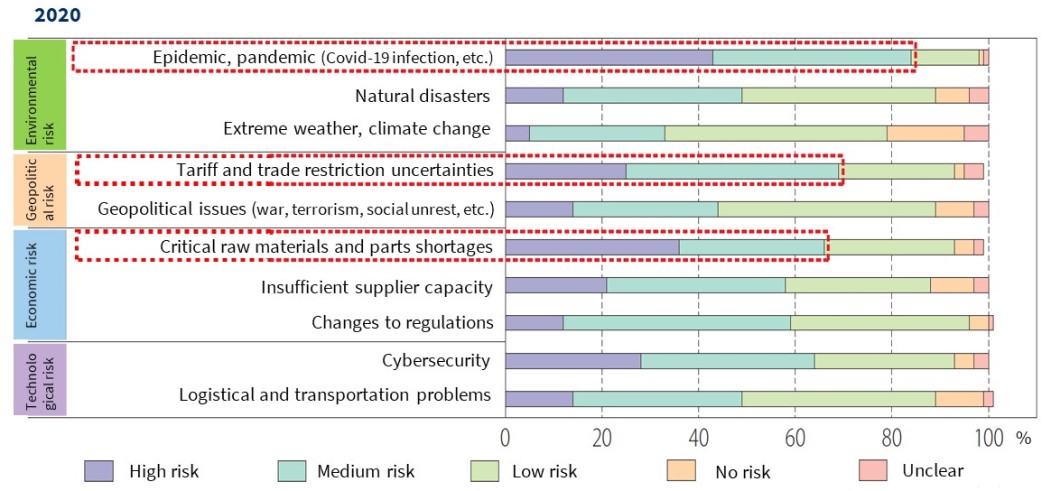

Supply Chain Risks in the Ministry of Economy, Trade and Industry’s “White Paper on Trades 2021”

Big lessons learned from a major earthquake

On July 16, 2007, at 10:13 in the morning, the Chuestu region of Niigata Prefecture, on Honshu’s Japan Sea coast, was hit by an earthquake with a peak seismic intensity of six upper on the Japanese scale: the Chuestu offshore earthquake. Only three years early the same region had been hit by the Chuetsu earthquake, which had a peak seismic intensity of seven.

When the earthquake struck, Toru Okayama was working in the Procurement Division of Toshiba Digital Solutions Group, in Toshiba’s Ome Operations. Although closed now, Ome, opened in 1968, had a storied history that included development and production of the world’s first Japanese language word processor and laptop computers,

“Earthquakes interrupt operations and distribution from the factories of parts suppliers in the affected region. Goods do not come in,” explains Okayama. “Back then, Toshiba handled a lot of mass-produced products, including TVs, personal computers, and white goods, and all of those factories were thrown into chaos. Of course, that was also true for Ome. However, the Chuetsu offshore earthquake happened at a time when business continuity planning, BCP, was attracting attention, and it provided us with an opportunity to seriously review our approach to procurement.”

Tohru Okayama, General Manager, TDSL Group Procurement Center, Toshiba Digital Solutions Corporation

The watchword was, “Don’t turn BCP into a manmade disaster”

The outcome of all this was that 2007 became the first year of procurement reform at Toshiba. It was also when the slogan of “don’t turn BCP into a manmade disaster” was coined.

In 2011, Okayama moved from Ome to headquarters, to head Group-wide procurement strategy and planning. This was just around the time when the 2007 reforms were beginning to reach their peak, and everything was in the midst of change. Based on the principles that all measures should be based on data, and that the supply chain should be visualized, five approaches were being implemented: 1. product-specific strategies; 2. partner strategies; and 3. strategies for reducing the cost of poor quality (COPQ); and these basic strategies were supported by 4. strengthening the procurement base; and 5. improving the human resources working in procurement.

The visualization showed the necessity of a multi-supplier system that takes into account of different countries and regions, which is in line with the cardinal rule of procurement: Do not rely too much on one company. However, the visualization revealed a blind spot in applying that rule.

Okayama takes up the story: “In visualizing supply chain data, we noticed there were concentrations of suppliers in the same region. It was a situation that would make procurement impossible in the event of an earthquake or some other disaster. We realized that we needed to disperse procurement across countries and regions, and because of that Toshiba came early to centralized management of supplier information. As a result, we were able to normalize supply after the Great East Japan Earthquake at a relatively early stage.”

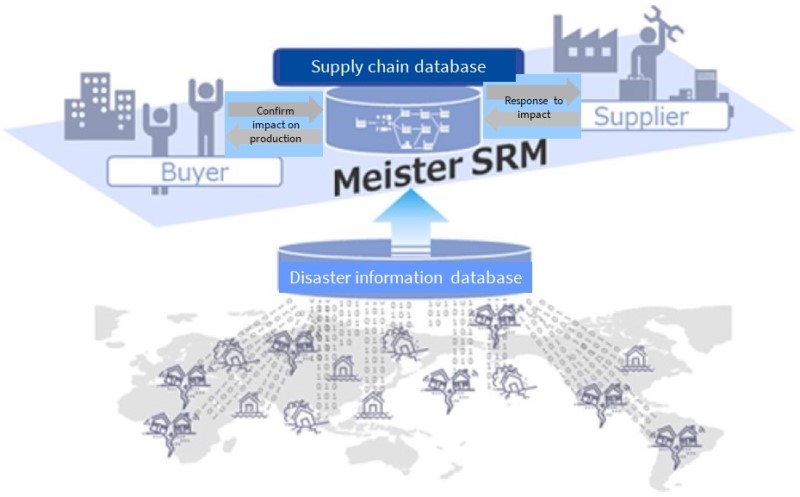

Image of BCP Management in Procurement Strategy

Changes from integrated procurement

Of course, procurement reforms are proceeding in areas other than disaster management, and the biggest of recent years is the integration of procurement functions. Prior to that, Toshiba advocated autonomy for its in-house companies, and even with the five approaches already discussed, the methods rules and management methods were decentralized and at the discretion of each company. Procurement by business division is not uncommon in large companies, but Okayama is quick to talks about its negative impact.

“Simply explained, the company can collectively bulk purchase 10,000 units of a part, but if each of 10 companies buy it, they will procure 1,000 each. Naturally, the discount rate is lower for 1,000 pieces. On top of this, if each company has its own procurement function, they will compete with on another to secure procurement specialists, which causes human resources issues. To put an end to issues like this, we integrated all procurement departments into the corporate procurement division in 2018.”

There were two considerations at that time; operational efficiency and thorough compliance.

“Integrating operations that has been distributed and inefficient won improvements,” says Okayama. “And we also improved compliance by strengthening group governance and ensuring thorough observance of the Subcontract Act and other laws. For example, we now have a procurement license system that we use to delegate work at the level of the individual, and we have been able to extend this throughout the company. Moving from decentralization to integration was a major turning point on the way to Toshiba’s current procurement strategy.”

With measures like this, Toshiba has continued to address procurement issues and work on reforms ahead of other companies. Meister SRM™ is a solution that reflects this knowledge, and Toshiba is now using it to resolve procurement issues faced by manufacturers.

Soaring raw material and labor costs, fluctuating exchange rates, a changing external environment… A sustainable procurement strategy is necessary

Meister SRM™ provides central management and effective utilization of information collected on a daily basis, such as material costs and supplier information. Looked at in another way it is a platform for communicating with suppliers that reduces procurement costs and risk in areas such as legal compliance risks and production interruption. What exactly does communication mean here? To find out, we asked Tatsuya Setoguchi, who is responsible for Meister SRM™ technology.

“The Procurement Department uses information from quotations, supplier surveys and other sources to devise its strategy,” Setoguchi explained. “There is a lot of uncertainty about now, and it is not unusual to see short-term fluctuations in the prices of parts we procure, driven by factors like soaring raw material and labor costs and exchange rate shifts. Every time this happens, we have to redo price estimates, but this can only be done with close exchanges of information with our business partners.”

Tatsuya Setoguchi, Senior Specialist, Toshiba Digital Solutions Corporation

Setoguchi also discussed how to prepare and respond to the recent international situation and other changes in the external environment, and the kind of procurement required by society.

“We need a system for exchanging information in emergencies; not only for natural disasters, but to understand whether a change in the international situation will impact production. We have also seen a recent increase in instances where ethical and sustainable responsible sourcing is required, and that has made in necessary to conduct surveys and evaluate our business partners. This can all be done by getting regular information from our business partners.

“Communication like this is really important in modern procurement. That is why Meister SRM™ supports two-way communication at all points of contact with our suppliers, and its functions include electronic quotations, supplier surveys, BCP management, general document exchanges and a general- purpose questionnaire, and procurement analysis.”

Setoguchi believes that Meister SRM™’s characteristics and strengths make it a solution that can grow with the customer. “Once Meister SRM™ is installed by a customer it evolves, depending on the degree of training in strategic procurement operations, and by expanding linkage in the value chain, such as design and manufacturing processes centered on procurement. The more the examples that are accumulated, the more Meister SRM™ will evolve, making it better able to provide easier-to-use solutions that are better suited to the circumstances.

Meister SRM™: Aiming for carbon neutral procurement and connection via a portal site.

Finally, we asked Okayama and Setoguchi about the future they see for Meister SRM™.

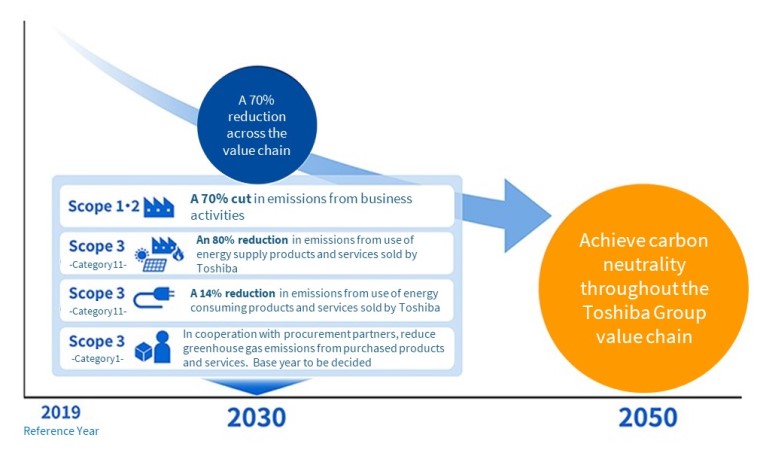

“In its ‘Toshiba Group Environmental Future Vision 2050,’ Toshiba sets itself the target of achieving carbon neutrality by 2050,” says Okayama. “In this context, we have to think about how the Procurement Division can contribute, and there are a few things to consider. In the not-too-distant future, CO2 itself could become a cost due to the introduction of a carbon tax. If that happens, I believe that buyers working in a carbon-neutral world will have a two-fold mission of securing cost reductions plus carbon reductions. With this in mind, it is very important to know how much CO2 products procured by Toshiba emit throughout the supply chain. This is what we call the Scope 3 calculation.

“Solving this problem with just our capabilities as people is basically impossible. For instance, a single factor like whether procured parts are delivered by plane or by truck will change the amount of CO2 emitted. Getting a firm grasp on this point is one of our challenges, and it’s an area where we will reinforce our efforts.”

Greenhouse gas reduction targets in Toshiba’s Environmental Future Vision 2050

In fact, efforts in this direction have already started. In collaboration with Zeroboard, a Japanese startup working on technologies to visualize carbon emissions, Toshiba has added GHG* emissions calculation and visualization functions to Meister SRM™. The outcome of this is the ability to prove higher value-added services, covering areas such as understanding GHG emissions in the supply chain and consulting on GHG reductions.

* GHG: Greenhouse gases: The collective term for gases such as CO2 and methane that cause the greenhouse effect

Setoguchi takes up the narrative: “Through DE, digital evolution, Meister SRM™ will digitize the existing value chain. We will then put our strengths into developing the data that process generates to achieve DX, digital transformation, that provides a platform.

“With DE, Meister SRM™ will initiate the digitization of information, and then aims to advance operations. However, with DX, Meister SRM™ must go on to become a platform, a supplier portal.

“We are now developing a portal site that will link companies that trade on Meister SRM™, visualize the entire supply chain, and allow suppliers to improve their operational efficiency and share information. While exchanging information, we also want to make it possible to calculate CO2 emissions throughout the supply chain, match companies and provide financing.”

The goal of the portal is to strengthen the supply chain in Japan and for global manufacturing industries. “We want to increase our competitiveness by being more resilient,” says Setoguchi, looking to the future.

Buy goods at a cheap price, as much as you like and when you want them. This basic mission of procurement will not change in the foreseeable future. However, what customers want, and the speed they require, the competitive landscape and social environment, are all in constant change. Okayama speaks emphatically: “While keeping pace with these changes, we will continue to evolve Meister SRM™ and Toshiba’s procurement strategies and solutions.”

![]()

Related Links

*This section contains links to websites operated by companies and organizations other than Toshiba Corporation.

Factory IoT Platform | TOSHIBA DIGITAL SOLUTIONS CORPORATION