Transforming mobility in the tough environment of mines -Advancing electrification that contributes to carbon neutrality

2024/05/14 Toshiba Clip Team

- Even in the mining sector, electrification can advance decarbonization.

- Safe, long-life rechargeable batteries are perfect electrification of mining equipment.

- Winning over prospective customers with custom-made simulations.

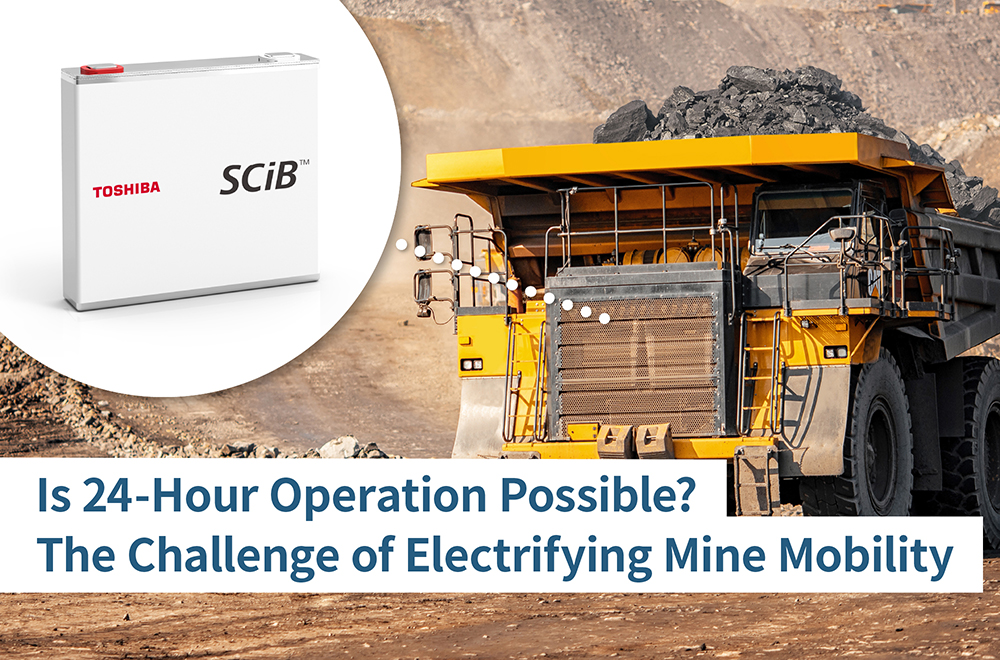

As demand for minerals grows worldwide, so too are concerns about decarbonization in the mining sector. One way forward is to bring electrification to vehicles, including dump trucks, and other mining equipment—but mines are a tough operating environment, and technology that supports electrification must be very safe and highly durable.

Toshiba is stepping up to the decarbonization challenge with its proprietary battery technology. Its SCiB™ rechargeable battery is highly safe, has a long life and recharges quickly, and the company has proposed its installation in dump trucks. The goal is to promote optimal electrification and decarbonization of mining equipment, and with it the provision of efficient charging facilities.

How did Toshiba come up with the idea of bringing the SCiB to mining, and what can it contribute to the sector’s decarbonization? To find out, we talked to two people in Toshiba’s Battery Division: Mr. Sota Goro, an Expert in the International Sales & Marketing Dept., and Ms. Saya Soeda, a Sales Engineer in the Battery Engineering Dept.

Toshiba rechargeable battery “SCiB™”

Why does mining equipment need batteries now?

From the iron ore that goes into industrial materials to the rare earth metals essential for electronic devices, global demand for minerals is soaring. The mining sector is more active than ever, but now within the context of the trend to advance carbon neutrality, where decarbonization is an urgent concern. Investors and consumers alike are aware of the need for sustainability, for the planet and ourselves, and are increasingly demanding decarbonization in all sectors of industry.

Against this backdrop, mining companies and mining equipment manufacturers are working on equipment electrification—the use of batteries. However, that is more easily said than done. Mining equipment is huge, needs strong motive power, and has to operate constantly for long periods on really rough surfaces that generate a lot of vibration. Any battery brought into that environment must be robust enough to withstand the rigors of use, and the ordinary lithium-ion batteries installed in passenger cars struggle to meet the demanding requirements. It has become a major hurdle for decarbonization.

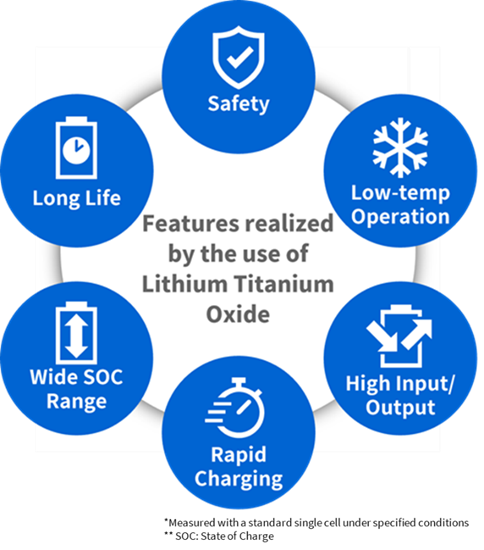

Toshiba is promoting decarbonization in the sector by leveraging its long-cultivated rechargeable battery technology. At the heart of the effort is its proprietary SCiB. Unlike most lithium-ion batteries, which employ a negative electrode made from a carbon-based material, the SCiB uses lithium titanate (LTO) that does not accumulate lithium metal on its surface. This is true even when the battery is charged quickly or used at low temperatures, and greatly reduces the risk of internal short circuiting that can cause battery accidents, including fire. Another plus is that there is virtually no electrode expansion or contraction during charging and discharging, so the battery is less likely to deteriorate. These characteristics ensure the SCiB operates safely through repeated charge and discharge cycles, with limited degradation, while maintaining high energy input and output and rapid charging.

Characteristics of the SCiB™

Goro underlines just how important this is. “The SCiB can be used for longer than other batteries, and it has a longer replacement cycle. Electrification is recognized as good for the environment, but that doesn’t mean anything if the batteries soon become unusable. We are also considering how we can reuse and recycle.”

Goro is also excited by the mining project, and has high expectations for business development. “Since the SCiB was commercialized in 2008, it has found wide use in hybrid vehicles, ships, and rail vehicles. With the strengthening trend to decarbonization, we started to look for new opportunities to develop, knowing that if there are areas with problems that cannot be solved by typical battery technology, there could be potential for using the SCiB’s characteristics. While doing research from this perspective, we came across electrification of mining equipment, and saw it was a great match. The SCiB is the perfect battery for the electrification of mining equipment used in really demanding environments. We saw it as a promising business opportunity: a market with high growth potential where we could make a significant contribution to solving a global-scale social issue.”

Sota Goro, Expert, International Sales & Marketing Dept., Battery Sales & Business Development Div., Battery Div., Toshiba Corporation

But there was more than that, as he explains: “Another important concern was compatibility between the environmental aspects of decarbonization and the business aspects, such as improved productivity through the introduction of SCiB. When you propose electrification, you really have to consider the characteristics of the customer’s business. A business only has value if it remains sustainable while it is being decarbonized. From that perspective, I felt that mining sites were somewhere where the SCiB could really demonstrate its capabilities.”

Soeda, who handles technical sales in the Battery Division, underlines just how important a point this is, and is eager to share her perspective as an engineer on why the SCiB is perfect for electrifying mining machinery.

“When we looked at mine electrification, our first thought was the large dump trucks that are used to transport minerals. Mines want to maintain high productivity, and the crucial factor for that is that the trucks operate 24/365. With passenger cars, what is wanted is batteries that increase cruising range from a single charge, but the productivity of dump trucks is most greatly affected by the amount of mineral a truck can carry in a single load. That means it is important to reduce the number of batteries on board and to increase the mineral load capacity as much as possible. The SCiB generates a large output, has a long service life, and shows little deterioration after more than 20,000 charge-discharge cycles. All that means the number of batteries can be reduced and we can secure enough space for the load.”

Saya Soeda, Battery Engineering Group 1, Battery Engineering Dept., Battery Div., Toshiba Corporation

The big question with electric vehicles is how best to deploy charging facilities along public roads, but for dump trucks that operate within the limited area of a mine, it is easier to arrange charging facilities and overhead wires for charging via trolleys as trucks move uphill along the route. This allows Soeda to conceptualize an entire electrification solution for a site and its dump trucks, including an optimized charging system, and to develop comprehensive technical proposals.

Custom-made simulations win prospective customers

The first step in the SCiB-centered promotion process is to introduce mining companies and mining equipment manufacturers, and also the battery manufacturers who sell the SCiB, to the benefits the battery can bring to the sector. Goro understand just how important this is, and is delighted about being involved in developing the business. “We approach all stakeholders in the value chain,” he explains, “upstream and downstream. It is essential to make sure they appreciate the impact electrification can have on a business, and its social significance, and that they also understand the superiority of the SCiB in this context.”

As part of this process, Goro and Soeda participated in an international mining industry exhibition held in Australia. Soeda spoke there as an expert on battery technology, and responded to questions from representatives of mining companies. As the person responsible for sales and marketing, Goro shared some key points that resonated with participants.

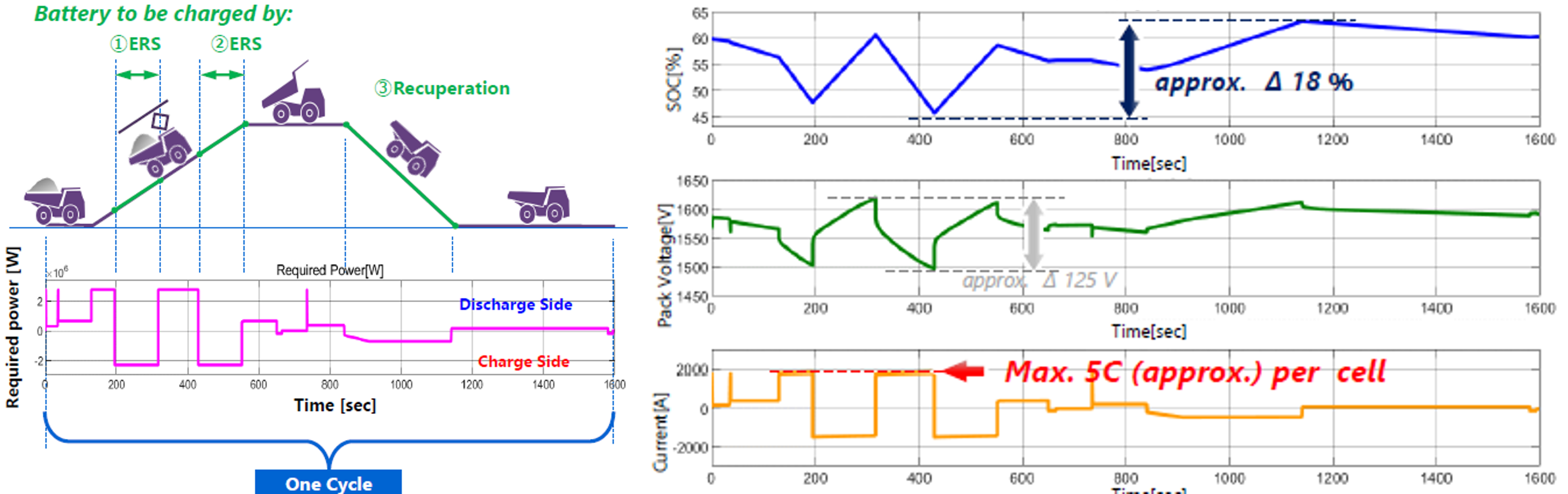

“Every mine is different in scale and in terms of site conditions,” says Goro. “All of the companies were interested in how many SCiB would be needed and how long they would last if introduced to their sites, so we got some very specific questions. “To come up with answers, we asked Ms. Soeda’s technical team to consider each customer’s site conditions and estimate SCiB lifespans. Toshiba’s ability to deliver such detailed simulations and provide customized data is one of our major strengths, and it was very well.”

An in-house SCiB™ simulation based on dump truck operating conditions.

Soeda found it inspirational to meet and talk with many people involved in mining. “Engineers naturally tend to concentrate on communicating the features and attractions of battery technology. However, what mining companies and mining equipment manufacturers are interested in is how much they can benefit from electrification. I had the chance to find out for myself the kind of approach that made a difference when talking to them, both about business and the environment.

“For instance, the diesel engines used in mining equipment have to be replaced every few years or so. We found that if these machines were converted to electric power, the batteries would need replacement only once every 10 years. That alone creates significant added value. On top of that, electrification realizes dramatic noise reductions and an improved working environment. Those points were also really welcomed.”

Mining electrification roadmap

The equipment electrification project built around the SCiB targets dump trucks, and expected to get them to market sometime in the late 2020s and 2030. Working toward this, Toshiba will support partner companies to carry out a series of demonstration tests, and use them to amass data and verify such things as operational efficiency and reductions in greenhouse gas emissions.

Both Goro and Soeda are aware that electrification of mining machinery is at an early stage around the world. They agree that, when trying to develop an unknown market, it is important to win the trust and positive opinion of stakeholders while building a record of success.

How the SCiB™ can contribute to the electrification of mining, an example with open pit mine.

Another area with potential for a breakthrough in bringing electrification to mining is the transportation trucks that operate in underground mines. While essential for carrying tools and equipment in and out of mines, most of those in use are diesel powered, which means there is always the risk of an underground fire that could become a major disaster. They also push out exhaust gases that, if left underground, impact on the health of the worker, and heat that must be removed from the mine. This ventilation requires extensive and expensive air conditioning, another cost that electrification can help to reduce.

Goro explains more. “Underground transport trucks are a mobility solution used at mines, like dump trucks. At an international exhibition we had the opportunity to meet an Australian company that was impressed by the SCiB’s very low ignition risk and zero emissions, and they adopted it for the electric light vehicles they build to meet needs for underground transportation in mines.”

An electric light vehicle from Australia’s ZERO Automotive, powered by an SCiB™

Finally, we asked about Soeda and Goro about future goals and aspirations.

“For the SCiB to be used effectively at mines, we really need to get a deep understanding of the mining sector,” says Soeda. “We need a concrete idea of the issues involved, and to continue technology development. This project has given us more opportunities to communicate with stakeholders. What I want to be able to do is quickly identify issues, even the smallest, and make more effective proposals.”

“The technology that goes into the SCiB gives it strong characteristics, and there are a lot of things only this battery can do,” says Goro. “I think promoting its introduction will help to solve problems that still face the world, and that has real social value; the electrification of dump trucks for mines is a truly symbolic example of this. We will continue to offer solutions that can be realized only with the SCiB, and do all we can to bring it into sectors other than mining.

![]()