Clean Water at a Lower Cost: Promoting Innovation in Wastewater Treatment

2018/06/27 Toshiba Clip Team

Water, water everywhere—but not enough of it, and most of it going to waste.

It covers about 70% of the planet’s surface, but only about 1% is usable to us as fresh water. That scant volume is the resource we rely on every time we have a drink, take a shower, use a toilet or cook fresh food. It sustains agriculture, and industry uses it in everything from steam turbines that generate electricity to cleaning equipment for semiconductors. Water is essential for much of what we do, and without it life on earth would be impossible. And a good part of all we use goes down pipes as wastewater.

But that’s not the end—more like a new beginning.

Running beneath our towns and cities are networks of sewer pipelines that carry waste and effluent to wastewater treatment plants. Once there, it goes through multiple phases of water treatment, including extensive filtering, exposure to bacteria, and disinfection.

Wastewater goes through multiple phases of purification

Bacteria might sound out of place in that list, but it plays its part by capturing very fine suspended solids still in the water after sedimentation filtering. It’s a process that requires constant aeration of the water, to provide a source of oxygen for the bacteria to grow, and turbulence to churn the water and bring the waste and bacteria into contact. In today’s systems, it’s a process that consumes a lot of electricity, paid for in our utility bills. Can it be made more cost efficient?

Clean water but less power

As a chief specialist in the Water & Environmental Systems Division at Toshiba Infrastructure Systems & Solutions Corporation, Yukio Hiraoka is keenly aware of the need to cut energy consumption in water treatment. “Wastewater facilities consume a lot of power—in Japan, 0.7 percent of all electricity. That’s a relatively high percentage for a single industrial process, especially once you realize that 30% to 60% of it is used for aeration.”

Hiraoka shares ideas for water treatment at a lower cost

At first glance, this seems unavoidable. Oxygenated water is a basic requirement for the wastewater treatment process, and that needs electricity. On the face of it, the equation is simple: the more electricity, the more oxygen; the less electricity, the less oxygen—but also less clean water. While Hiraoka is all too familiar with this, he is also determined to change the equation and reduce power consumption with no reduction in clean water output.

Hiraoka explains more. “In water treatment, we err on the side of caution, so we tend to put more oxygen than necessary into the aeration process. That ensures it works well enough to meet strict treatment criteria, but we don’t require this high level of oxygen at all times. There are patterns in life. People rarely wash dishes in the middle of the night, for example, and the composition of wastewater changes. Electricity consumption can be cut if we can understand that and control the amount of oxygen accordingly.”

A lone sensor secures lower cost water purification

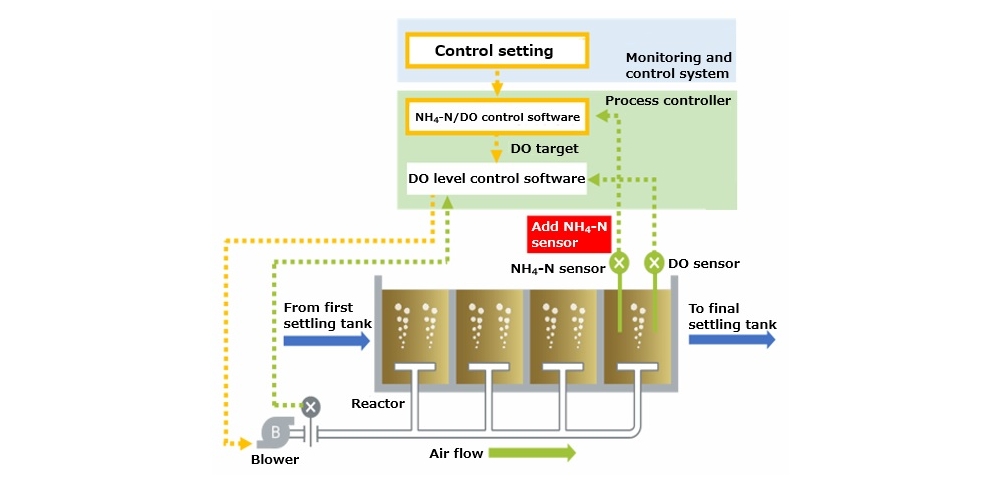

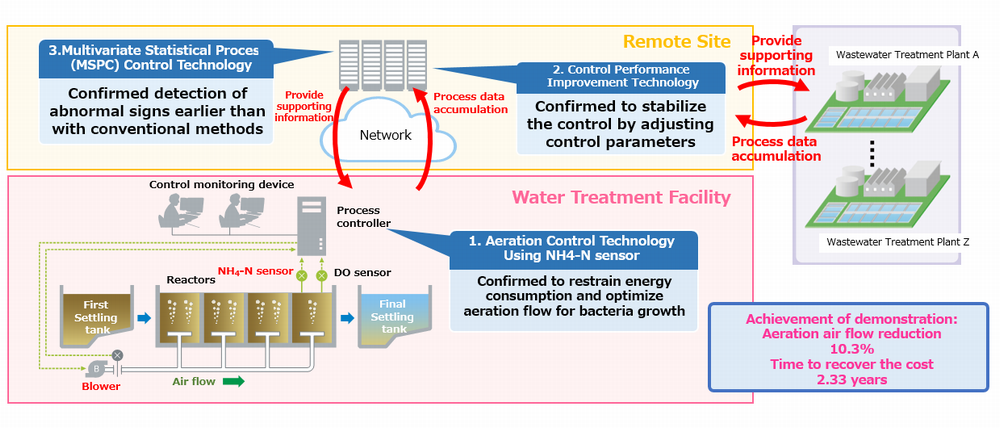

Ammoniacal nitrogen, NH4-N, is a widely used marker for testing water quality—the more of it, the lower the water quality. Building on this, Hiraoka and his colleagues at Toshiba have developed a solution that uses sensors to automatically detect the concentration of NH4-N, along with the volume of dissolved oxygen (DO). This allows calculation of the minimum air flows into water needed to maintain the DO that promotes optimum bacterial growth. In operation the system allows air flows to be managed, and reduces overall power consumption.

“The beauty of the technology is the simplicity of its structure,” explains Hiraoka. “Our system requires only one NH4-N sensor, plus dedicated software to calculate the optimum amount of air flow into current systems.”

Work on the technology started in 2012, and two years later its functionality and cost advantages earned it selection in a demonstration research project funded by Japan’s Ministry of Land, Infrastructure, Transport, and Tourism of Japan. In practical use at the Homan River Wastewater Treatment Plant in Ogori, Fukuoka prefecture, variable air flow proved to be 10.3% lower than constant air flow control, a real saving in power.

For Hiraoka, this achievement is only a beginning. “One of the challenges is the automation of human operation. Doing that would make systems easier to handle and promote more cost reductions. We also need to look at ultimate use. If water treatment is for cleaning, not drinking, the required water quality level can be lower. That would also reduce costs. You see, many things can be improved when looked at from a different perspective.”

It’s no small achievement that billions of us around the world can turn on a faucet and get a stream of clean, drinkable water; and it’s no small concern that billions more can’t. People like Hiraoka are developing technologies that aim to bring clean, affordable water to all.

![]()