Zero Electrical Resistance: Turning Dreams into Reality

2019/06/05 Toshiba Clip Team

In 2013, the Higgs boson came into our collective consciousness—even the least scientific-minded of us—when it won the Nobel Prize in Physics. Though its existence had been theorized since 1964, it wasn’t until 2012 that it was actually discovered. What you may not know, is that this discovery was aided in part by Toshiba superconductivity technologies.

Superconductivity is the phenomena of zero electrical resistance that occurs in certain materials at very low temperatures. Substances that have become superconductive are known as superconductors, and when coiled, they are known as superconducting magnets. When supplied with a strong electric current, these magnets produce magnetic fields of strengths that would be impossible to achieve through other methods.

These superconducting magnets have come into use in a wide variety of areas, from the industrial sector (semiconductors, etc.) to the medical sector (MRIs, etc.), transportation sector (linear motor cars, etc.). They have become an integral—if relatively invisible—part of our daily lives.

Here, we feature a dialogue between Yukihiro Sumiyoshi and Shohei Takami, the former a long-time engineer that contributed to the development of superconductivity technologies in Japan, and the latter a mid-level engineer currently working at the very front lines of this same technology. The question we asked was simple—what does superconductivity mean to you?

The dawn of superconductivity

――Toshiba began its research into superconductive materials in the early 1960s. Since then, the company has remained at the forefront of superconductor technology, making good use of the ever-advancing research in superconductivity in general.

Sumiyoshi: It was in the 70s that people began trying to use superconductors as magnets. When I joined Toshiba in 1981, the development was already underway in Japan, and the company—looking to develop its own technology—was working with Tohoku University on research into superconducting magnets.

The question at that point was how strong of a magnetic field we could create. Superconducting magnets were good in that they could create a very strong magnetic field, but they had a weakness—if the magnetic field became too strong, they would gradually lose their ability to maintain their superconductive state. Another important question was how large of an area we could get a magnetic field—of the same strength—to cover.

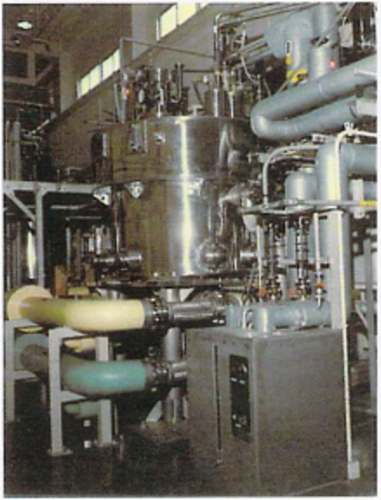

And what came out of this joint development process with Tohoku University was a 12-tesla superconducting magnet. Tesla is a unit of measurement that measures the strength of a magnetic field, and at 12 tesla, our superconducting magnet was considered the world’s strongest at the time.

This superconducting magnet was delivered to the Tohoku University Institute for Materials Research. There, it was later combined with a regular magnet to form a hybrid magnet of 31.1 tesla—the world’s strongest continuous-field magnet.

30-tesla hybrid magnet for the Institute for Materials Research, Tohoku University

This was the dawn of superconductivity, and there was a lot we still didn’t know about it. Everyone was working the same level of knowledge and understanding—university professors, my bosses, fresh new employees like me. It was in this kind of environment that superconductive materials gradually evolved.

Around 1985, the company started developing a superconducting magnet for MRIs—a kind of medical equipment—and I was to be a part of the process. Unlike CTs, which use X-rays, MRIs use magnetic fields to “photograph” tomographic images. With a stronger magnetic field, you could get more accurate diagnostic imaging, hence why superconducting magnets were being considered for the job.

Yukihiro Sumiyoshi, Nuclear Energy & Machinery Equipment Dept. Keihin Product Operations, Toshiba Energy Systems & Solutions Corporation (title at the time of the interview)

Takami: The development for the MRI magnets was different from the research with Tohoku University, it was for mass production. That must have made it difficult, because even if the finished product was high-quality, customers wouldn’t want it if it was too expensive.

Sumiyoshi: You’re exactly right. Of course, there were also issues on the technological side, specific to making superconducting magnets for MRIs. However, on top of all that, we also had to make them high-quality and cheap, and mass produce them as well. At the time, we were involved more in developing record-breaking samples, like our 12-tesla magnet with Tohoku University. So we had to really overhaul our way of thinking as we developed these new magnets.

A journey in superconductivity: from regret to breakthrough

Sumiyoshi: Technically, we were developing these MRI superconducting magnets for medical equipment manufacturers. But we knew that at the end of that chain, it’d be regular people that would be using the equipment. A B2B2C* model, if you will.

*An abbreviation of “Business to Business to Consumer”.

MRI superconducting magnets developed at the time

Looking back, though, it’s clear that we were too focused on improving the accuracy of the magnetic field and creating this incredible superconducting magnet, and not enough on the “C,” the end user. We look back on it now and really regret that we weren’t able to design it in a way that was conducive to the needs of the actual users.

――Did this kind of regret have a great impact on the way Toshiba approaches development in superconductivity?

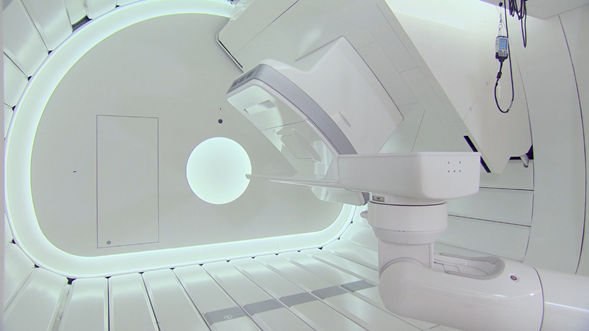

Takami: Yes. I personally was involved in the development of a superconducting magnet for heavy iron therapy equipment, which are used in heavy-particle radiation therapy for cancer, and I think the fact we were able to design these machines specifically for the end user led to our breakthrough in development.

Takami

――Heavy iron therapy is a cutting-edge form of cancer treatment that uses a form of radiation known as heavy-particle radiation. The treatment is accomplished by treating tumor sites with beams of accelerated heavy particles, but in order to direct the path of the particles, and thus the radiation, you would need a very strong magnetic field.

Sumiyoshi: Back in the day, the machines couldn’t control the path of these heavy particles, and patients were forced to keep their bodies tilted during therapy. But of course, for cancer patients, this was incredibly hard on the body.

So we decided to use semiconducting magnets in “the gantry”, which is the part of the machine that produces the heavy particles and the radiation, and in doing so managed to make the gantry much smaller. It was a revolutionary idea—to have the gantry move 360 degrees, all around the patient, instead of moving the patients themselves.

Heavy ion therapy equipment with rotating gantry (Courtesy of QST/NIRS)

Takami: We needed all kinds of technology to make a rotating gantry, and one of these was a technology that would allow high-speed manipulation of the strength of magnetic fields. To make it so that the heavy particles got where they needed to go, regardless of where the treatment area actually was, these machines had to manipulate the strength of the magnetic field, and accurately direct the path of the radiation.

Regular superconducting magnets were not very good at this kind of high-speed manipulation, and would quickly overheat. We were able to develop a technology, however, that allowed this kind of high-speed manipulation, and so we were able to make a rotating gantry, and even cut down on treatment times for the patients themselves.

We feel, now, that we can make products that are designed for the people who actually use them. As a developer, there’s no better feeling than that.

Sumiyoshi: Even now we’re working with universities and research institutions towards cutting-edge technologies. And this cycle is what’s important—using the technologies we build from the research to make even better Toshiba products. We believe our mission is to take this cycle, and pass these technologies on and on and on, into the future.

Sumiyoshi (left), Takami (right)

Takami: When it comes to mass production, people want things that are affordable, but also high in quality. So as a company, we have to incorporate these cutting-edge technologies into our mass-produced products, and raise the quality of our products in general.

In recent years, they’ve made their way into our daily lives—into our medical equipment, linear motor cars, and more. And this is just the tip of the iceberg. I believe it’s especially important in this kind of environment to consider the needs of the end user, and incorporate these needs into products from early on in design and development.

――The heavy-particle radiation machine that Mr. Takami was involved with also features various other technologies, in addition to the technology that we discussed that allows for high-speed manipulation. We’ll ask Mr. Sumiyoshi and Mr. Takami more about that the next time.

![]()