Ozonation in Drinking Water Treatment

2018/09/12 Toshiba Clip Team

Food and water are our most fundamental needs, and as the global population grows from 7 to 8-billion, and more and more people flock to cities, ensuring a reliable supply of good and safe quality water has never been a more pressing issue.

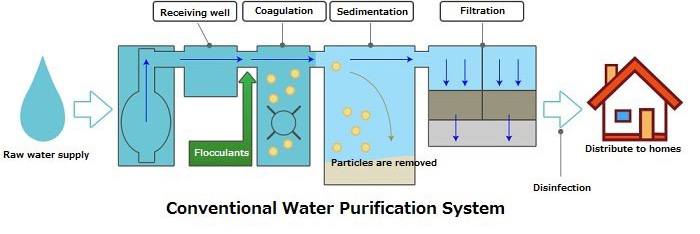

The conventional drinking water treatment, developed in the U.S. in the 1920s, consists of coagulation, flocculation, sedimentation, rapid sand filtration and disinfection. In the coagulation and flocculation processes, chemicals called coagulants bind particles together and make more easily settled flocs. After removal of flocs in the sedimentation basin, chlorine is added—a common disinfectant and a smell familiar to most of us.

For aesthetic and safe quality of water

Rapid sand filtration is an effective treatment for drinking water, but doesn’t solve all problems. Kie Kubo, a specialist in environmental engineering at Toshiba Infrastructure Systems & Solutions Corporation, explains why: “There can be a musty odor in the water, especially if it contains a lot of contaminants. That was a big problem about 20 years ago, due to deterioration in the quality of water sources.

Kubo shares her expertise on water treatment

“This problem was solved by adding more chlorine. However, increased chlorination caused another problem. Chlorine doesn’t remove odors completely, moreover it combines organic matter and generates trihalomethanes, known carcinogens.”

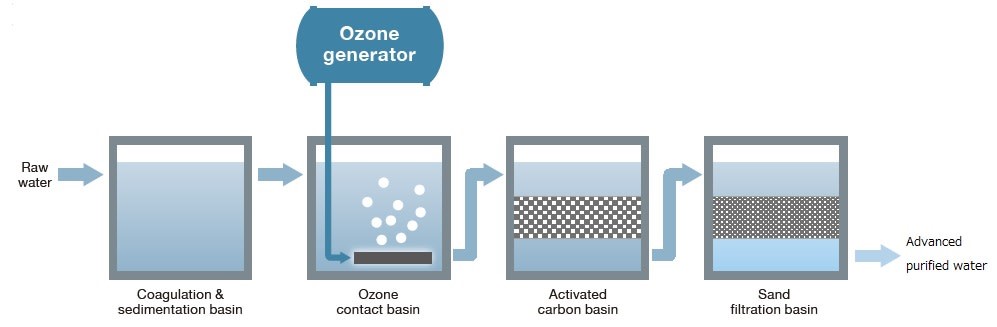

To eliminate desirable odor and prevent the production of trihalomethanes, a combination process of ozonation and biological activated carbon (BAC) filtration was applied in water works. Ozone resolves organic compounds into simpler organics that are more readily biodegradable, and the BAC media can provide biological oxidation and absorb organic molecules.

The advanced water treatment system is the combination of ozonation and activated carbon filtration

Toshiba started to manufacture ozone generators for water purification back in the 1970s. With over 40 years of experience in the field, the company has developed ozone-related technologies that contribute to the production of good-quality water. Toshiba has already installed more than 100 ozone treatment systems in Japan. Its most recent and advanced ozone generators are the Toshiba Green Ozone Generators, more familiarly TGOGS™, launched in 2013.

Toshiba’s high efficiency ozone generator TGOGS™

Advantages of ozone

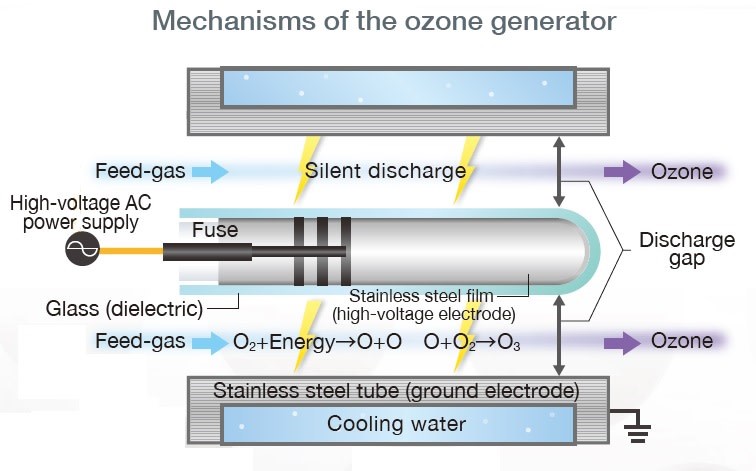

How does ozone purify water? Ryutaro Makise, a senior specialist explains. “Ozone is a strong oxidant that resolves organic compounds that cause color, taste and odor, and disinfects water. It improves water quality and safety dramatically, reducing the need for chlorine and preventing production of trihalomethanes.

Makise explains why Toshiba wanted to use a stainless steel thin film

The ozone vessel consists of stainless steel tubes, electrodes, and fuses. There are two kinds of electrodes. The high voltage electrodes are called discharge tubes. They are made of glass tubes and have internal coatings of stainless steel. The other electrodes are grounded stainless steel pipes. The electrical discharge appears in the very narrow gap between these two electrodes. The electrical energy splits the oxygen molecules into oxygen atoms, these atoms combine with the other oxygen molecule to form ozone(O3).

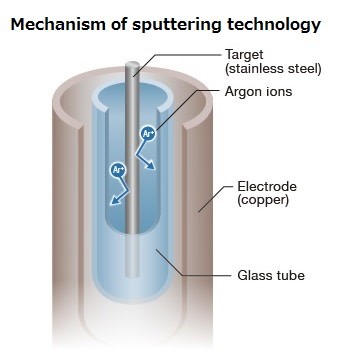

Toshiba has taken a unique approach to the design of the discharge tubes. “The discharge tubes are key point for TGOGS™,” explains Kubo. “Forming a thin film of stainless steel inside a small diameter glass tube is very difficult, but we achieved it with a lot of effort, and Toshiba’s advanced expertise in sputtering technology.”

Why stainless steel? Other companies apply other materials as electrodes. Why did Toshiba want to stay with stainless steel even though it required a really difficult sputtering technology?

Makise explains: “The first thing to bear in mind is that ozone is a very strong oxidant, so you need an oxidation-resistant material, like stainless steel. Also there’s another problem, nitric acid, which is produced during operation. Once again, stainless steel is corrosion resistant to nitric acid. The very thin stainless steel made by sputtering technology achieved very light discharge tubes, which makes assembly and maintenance of the ozone generator easier. Every way we looked at it, stainless steel was clearly the best material for TGOGS™.”

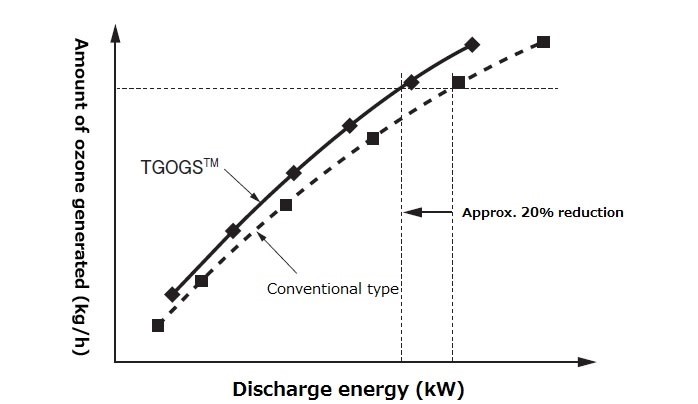

Toshiba’s innovations eventually reduced the diameter of the discharge tubes by 60%, allowing more to be installed in the ozone vessel, and also making the ozone vessel itself smaller. In addition, the very narrow and highly accurate discharge gap achieved with small diameter discharge tube, makes it possible to generate ozone highly efficiently. TGOGS™ provides enhanced energy efficiency while reducing the footprint and weight of the machine. The air-fed type achieved a 20% decrease in power consumption compared with the conventional model, while the oxygen-fed type accomplished a 12% reduction of power consumption.

Compared with a conventional type, TGOGS™ generates the same amount of ozone with approximately 20% less discharge energy (air-fed type)

In Japan, water works along the two biggest rivers (class A river), the Tone River and the Yodo River, major water sources for the Tokyo and Osaka metropolitan areas, respectively, have been completely upgraded to this advanced water treatment method. Toshiba’s next step is to move into overseas markets.

Kubo says, “Developing countries have not made much headway in introducing advanced water treatment. To make TGOGS™ more competitive and get it installed in those countries, we need more improvements: to use different materials for different climate conditions, simplify maintenance, and establish local procurement.”

Being able to provide solutions for aesthetic and safe water to more people, that is something that constantly motivates Kubo and Makise.

Kubo and Makise, ready to expand ozone business abroad

![]()