Superconducting Motors are on the Flight Path to Carbon Neutral Planes, Part1 – Breaking Down Barriers No One has Overcome, for the Future of Aircraft

2023/04/07 Toshiba Clip Team

- The quest to make aircraft carbon neutral

- How Toshiba developed a light, compact, high-power superconducting motor

- A solution for a global issue. Working with partners to change the future of aircraft

In October 2022, the International Civil Aviation Organization, the UN specialized agency that coordinates and develops international air navigation and travel, set new targets for reducing CO₂ emissions from international flights: a 15% cut from 2024 on, against 2019, and the achievement of net zero by 2050. The mobility industry is being transformed as electric vehicles replace gasoline-powered cars and grow in popularity, and now aircraft are also expected to replace fossil-fuel powered jet engines with electric motors. There is only one problem. It is currently very difficult to do that.

The solution to this global challenge can be found in Toshiba’s superconducting motor, a breakthrough that combines deep know-how with advanced technologies. “What we need is an innovative approach geared to the unique requirements of aircraft; improvements to existing technologies will never solve the problem,” says Fumitoshi Mizutani, who played a central role in the motor’s creation as the development project leader. The key concerns were to harness lightness with high power. In this article, we take a behind-the-scenes look at the progress of the project, to find out how it progressed.

A world’s first in superconducting motors in the face of fierce global competition

“If we are going to achieve the ICAO’s 2050 target of net zero CO₂ emissions from international flights, we have to replace aircraft engines,” Mizutani explains. “That is why there is a lot of interest in superconducting motors.”

Fumitosi Mizutani, Specialist, Fourth Advanced System Design & Engineering Group,

Advanced System Design & Engineering Department, Isogo Nuclear Engineering Center, Power Systems Div.,

Toshiba Energy Systems & Solutions Corporation

Superconducting motors make it possible to simultaneously achieve the lightness required for mounting on aircraft and the high output needed to replace jet engines. That is why research institutes, universities, venture companies, and large corporations in countries around the world have started to develop them. However, there is a big but, as Mizutani explains.

“Medium- and long-range aircraft will have the greatest impact on cutting CO₂ emissions. In our work, we decided to adopt an aircraft with multiple small motors as our development model, with the aim of realizing a motor with a 2-megawatt output. However, when we initiated the project, no one in the world had completed a superconducting motor with an output exceeding 2 MW that was also light and compact. Here at Toshiba we decided we had to do something to solve this problem for the world, and we packed the project with advanced technologies.”

As competition grew, Toshiba began development work in November 2019, starting with a worldwide survey of development status and a study of technical concepts based on the survey. At that point, and as the investigation of related research progressed, the height of the hurdles ahead became clearer. But Mizutani wasn’t fazed. In his heart of hearts he believed, “Toshiba can do it.”

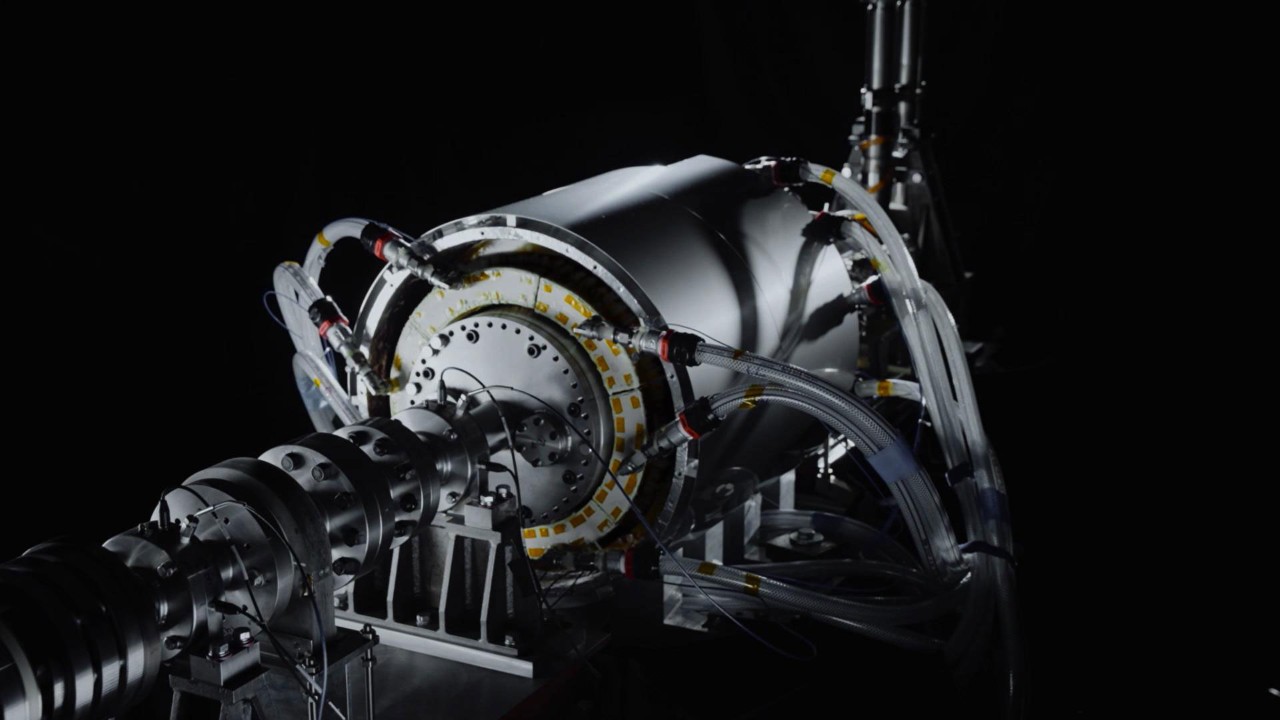

As he explains, “Toshiba manufactures turbine generators and has many technologies for the manufacture of high-speed rotating machines. We also have the superconductivity technology necessary for light, compact, high-power motors. We were confident that we could produce the world’s first superconducting motor by fusing the two.” That was achieved in March 2022, only two-and-a-half years after the launch of the project. It was a true breakthrough, less than one-tenth of the size and weight of a conventional motor with equivalent output.

The light, compact, high-output superconducting motor that will contribute to carbon neutrality

The advantages offered by superconductivity

Before going behind the scenes of the development project, we should take a look at just what a superconducting motor is, and how it differs from an ordinary motor. Ryo Fuchimoto, a member of the project team from the word go, and currently in the Corporate Planning Department of Toshiba’s Energy Systems, can tell us all we need to know. Since joining Toshiba, he has designed turbine generators for thermal and nuclear power plants, and he was the design leader for the motor’s rotor and its overall assembly.

Ryo Fuchimoto, Specialist, Business Strategy and Planning Div.,

Toshiba Energy Systems & Solutions Corporation

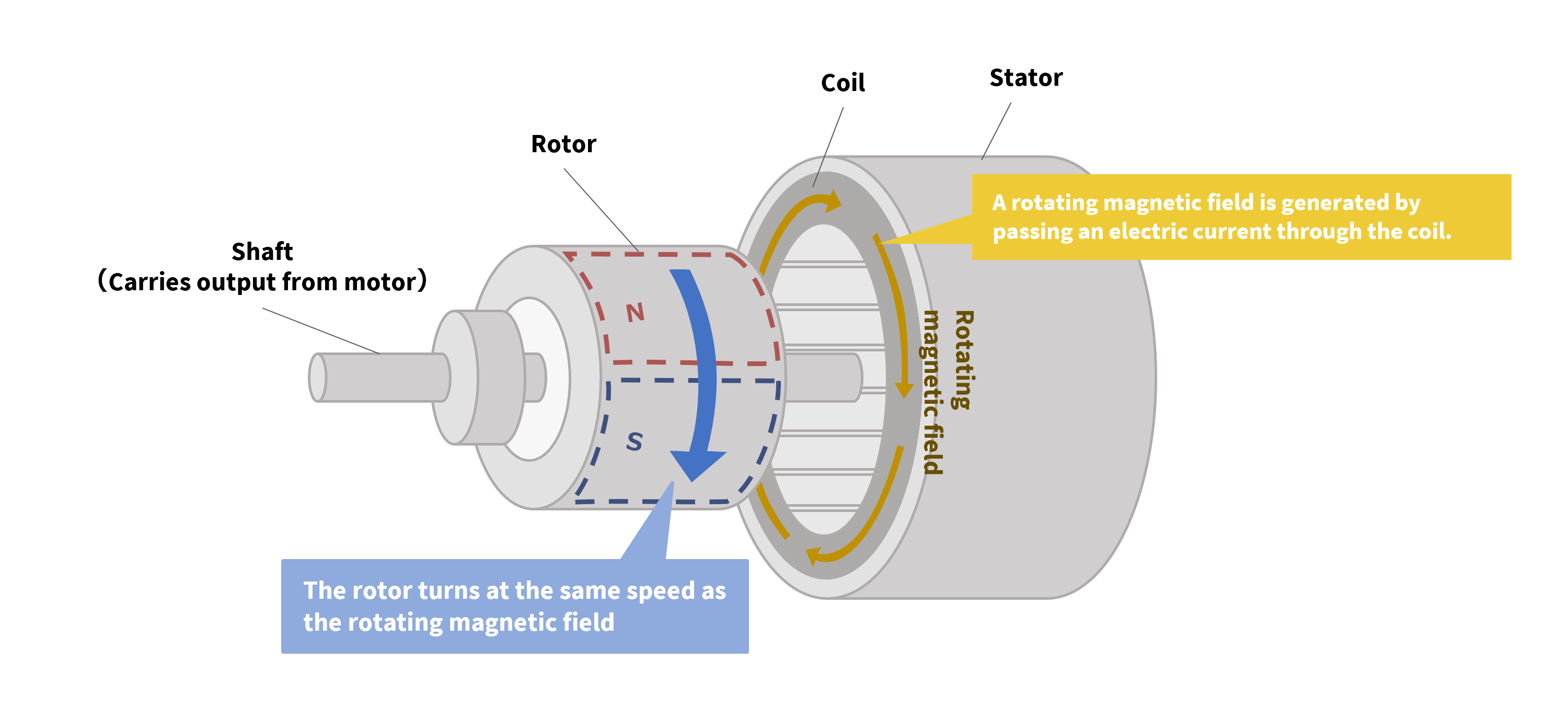

“How can superconducting motors, which are small and light, generate high output power?” Fuchimoto asks rhetorically. “The reason is simply explained from the principle of the motor. It has a part that turns, the rotor, which is fitted with permanent magnets and housed in the stator, which is stationary and contains a coil that surrounds the rotor. Alternating current applied to the coil generates a rotating magnetic field that attracts the rotor’s magnets, causing it to rotate at the same speed.

“If we want to increase a motor’s output without changing its size, we need to increase the strength of the magnets in the rotor and of the rotating magnetic field in the stator. As permanent magnets in the rotor have limitations, we replaced them with electromagnets that generate a stronger magnetism when electricity is applied.”

The mechanism of a superconducting motor

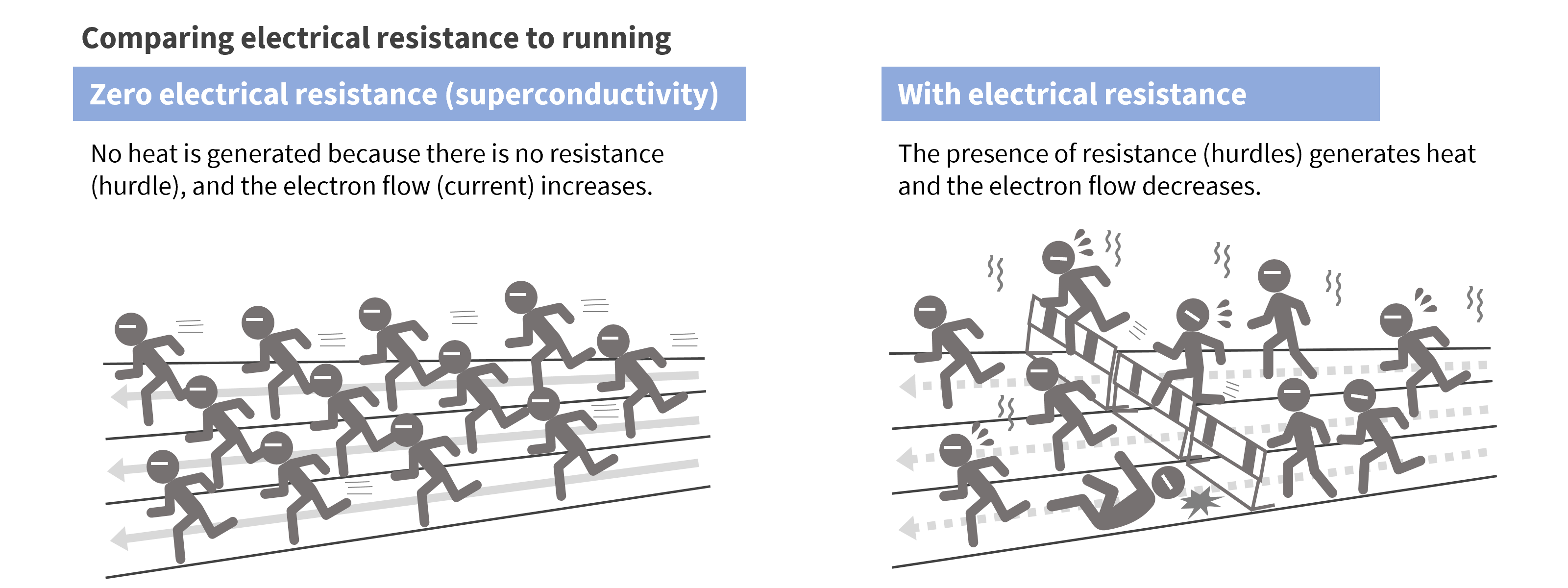

However, there is a problem. When current is increased, electrical resistance in the coil generates heat; if the temperature gets too high it damages the coil. With ordinary coils, there is a limit to how much output can be increased without changing the size of the motor.

“There is a solution to this,” explains Fuchimoto. “Make the electromagnet coils superconductive. Superconductivity is the point of zero electrical resistance, and it is achieved by replacing normal coils, usually made with copper wire, with coils made from a superconducting material. When resistance in the coil is zero, even the application of a large current does not generate heat, and a strong magnetic field can be obtained. Making the electromagnetic coil of a motor a superconductor is the key to increasing the motor’s output to the maximum while maintaining a small size.”

With superconductivity, there is no electrical resistance, and current can be increased to the limit

Another essential for superconducting motors is cooling. For the motor to rotate at very high speeds, the coils must be kept at an extremely low temperature that maintains superconductivity and zero resistance, Keeping a moving object at a cryogenic temperature is a constant, major challenge in the development of superconducting motors. The project team overcame it by devising a rotor cooling structure, a manufacturing process and refrigerant flow method in consultation with experts from Toshiba working in diverse fields.

Home appliances, air conditioning, nuclear power, thermal power generation… A team that brought together Toshiba’s strengths

The first step in the development process was to solve the conundrum of rotating delicate superconducting materials at high speeds, in a structure that could withstand centrifugal forces of approximately 8,000G generated by the high-speed rotation—and bear in mind that astronauts experience only 3 to 4G during a rocket launch. In the early stages of a project, it is natural that there are limits to the resources that can be spent on something no one has succeeded in achieving, and the project advanced through repeated trial and error.

It was at this point that Tadahiro Nakayama of Toshiba’s Manufacturing Engineering Center expressed an interest in joining the project.

Tadahiro Nakayama, Expert, Electronics Control Technology Research Department,

Electronics Unit Packaging & Control Technology Division, Corporate Manufacturing Engineering Center

“The Manufacturing Engineering Center researches and develops technologies and systems for Toshiba Group’s manufacturing activities,” explains Nakayama. “I have worked on R&D of motor-related technologies for home appliances, air-conditioning and vehicles, and we have provided these technologies to numerous divisions. That led to the opportunity to introduce our work to Mr. Fuchimoto’s department.

“Mr. Fuchimoto told me that he was developing a superconducting motor, and he asked me to tell him about the design of small, high-speed motors, and about what exactly it was that I did. It all started with these questions.”

After hearing all about the project and its challenges, Mr. Nakayama decided he wanted to be part of it—and his timing was good. He became leader for engineering design and manufacture of the stator just as they were becoming important concerns for the team. Through moves like this, pieces necessary for the completion of the motor were put in place and the project advanced.

A fusion of advanced technologies in diverse fields realizes an innovative superconducting motor

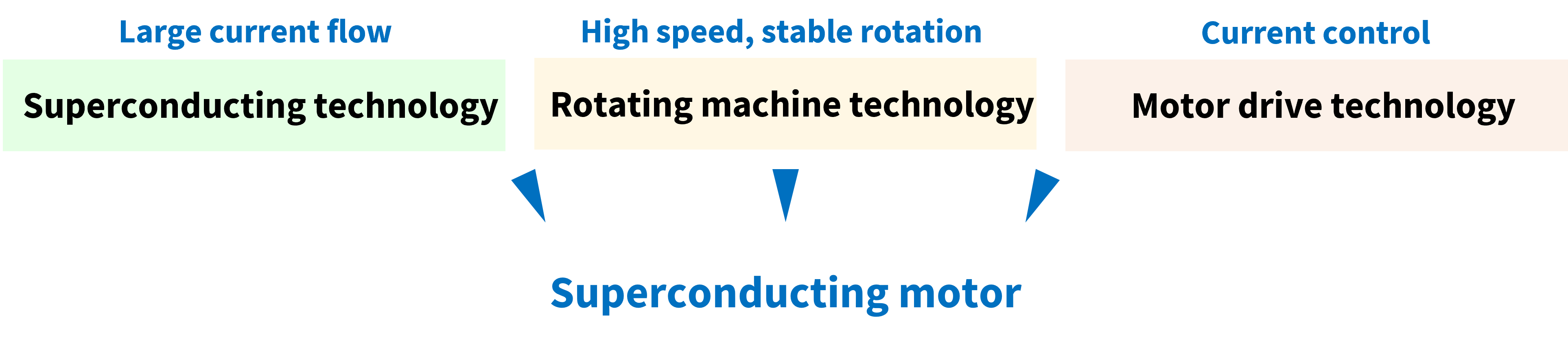

Fuchimoto recalls some of key development requirements. “We had to design a structure flexible enough to withstand shrinkage due to cooling, but strong enough to handle large G-forces.” By this time, the team had more than 30 members, with backgrounds in superconducting technology, rotating machine technology, and motor drive technology. Through a process of repeated design and verification, they settled on the form that they wanted to finalize.

Weekly progress reports and regular meetings to confirm design and manufacturing policies helped to sustain the team’s sense of purpose, as did Mizutani’s management of the development schedule, and his encouragement in the team members of a strong belief in their ability to complete the superconducting motor.

Now, the team is looking to form multiple partnerships, as Mizutani explains, “Since Toshiba announced the superconducting motor, we have had inquires not only from aircraft companies but also from automobile, railroad and other mobility companies, engine manufacturers, and universities. They all tell us that they are surprised that 2MW output can be realized with such a small size”.

Toshiba’s superconducting motor takes on a global problem. It promises a carbon-neutral solution no one has achieved before, and it could well change the future of aircraft. In Part 2 of this article, we will talk to some of the young engineers who worked with Mizutani, Fuchimoto and Nakayama, and find out how they overcame technical challenges on the way to developing the superconducting motor.

![]()