Toshiba rides the coming wave of industrial IoT standardization

2023/06/12 Toshiba Clip Team

- Toshiba brings its pride as a manufacture to value creation in the industrial IoT space.

- TIRA*1, an innovative perspective for co-creation, essential to Toshiba’s strategy in the industrial IoT space.

- What service does Toshiba’s “last one mile” advantage in hardware allow it to provide?

‘What kind of manufacturing company is Toshiba aiming to become?’

Josh Kataoka who works at Toshiba’s Digital Innovation Technology Center, which handles the company’s development and delivery of digital service infrastructure, has a ready answer: “I think the key to this question is TIRA. The greatest change at Toshiba in the past decade is our shift to B2B businesses such as infrastructure and energy. With B2C businesses like consumer electronics, you can see the end user. With B2B products and services, it’s more difficult for us to see what kind of value we’re delivering.”

Advances in digitalization and dramatic changes in our societal landscape have questioned many companies their raison d’etre. What does it mean to be a company in this day and age? What kind of world, what kind of value do Josh and others at Toshiba envision for the future? What can TIRA do? The answer lies in the Toshiba’s Vision and Values, which out the conviction needed to make a difference in this increasingly complex world.

Toshiba creates new value in the industrial IoT space, with pride as a manufacturing company

Goal No. 9 of the SDGs is as follows: “Build resilient infrastructure, promote inclusive and sustainable industrialization and foster innovation.” Countries, companies, and universities across the world have brought together their myriad different technologies to try to accomplish just that. One approach seen as effective at solving various social issues involves the use of IoT (Internet of Things)*2 technology, or the data acquired from things (objects). IIoT (Industrial IoT) in particular has gained considerable momentum in the Western world in recent years. Germany, for instance, has set forth “Industrie 4.0” as a national strategic initiative, while the U.S. has established the Industry IoT Consortium (IIC*3), which advocates for industrial IoT technologies.

“These are the trends worldwide, and Japan has fallen behind,” says Josh. His concern for this development is palpable.

“At the heart of everything Toshiba does is a desire to deliver value for the sustainability of society and the planet. IIoT technology is essential to achieving that. Put more bluntly—if we don’t harness the power of data by utilizing IIoT, we will not be able to maintain our value as a company,” says Josh.

Josh Kataoka, General Manager, Planning Office, Digital Innovation Technology Center, Toshiba Corporation

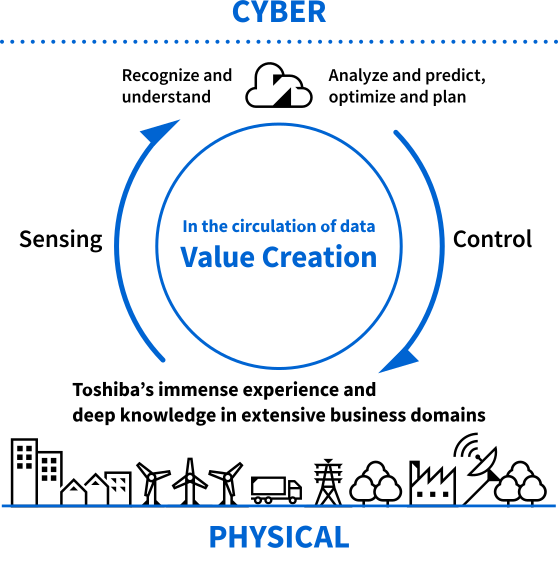

There are, of course, various different ways to utilize data. We have already mentioned IoT, which acquires data from industrial equipment and facilities. There is also IoP (Internet of People), which acquires data related to the knowledge and behavior of people; and IoS (Internet of Service), which collects data from the operation of services and systems. Data acquired in these ways is aggregated in cyber space and analyzed to generate insights that fed back into our lives as meaningful information, creating new value.

“In B2B business, Toshiba’s customers are companies. There are almost no opportunities to interact with the end users that exist beyond these companies. But if we as Toshiba want to understand what sort of value end users are seeking, and to be able to reflect that swiftly in our customer’s products and services, we have to make in-depth, meaningful proposals.

That’s where IIoT is so important, because data allows us to visualize what Toshiba offers. It’s precisely because we’re a manufacturing company, with part of our business devoted to hardware, that we can consider the value that is delivered all the way down to the end users. We want to take pride in that, and that’s the mindset we’re approaching this with.”

So what is this Toshiba IIoT strategy that Josh describes with such passion? To figure that out, it is necessary to understand the Toshiba IoT Reference Architecture (TIRA), which Josh is working to develop and promote, and TOSHIBA SPINEX, the service built on top of this architecture.

TIRA as a perspective for co-creation, essential to Toshiba’s strategy in the industrial IoT space

TIRA is a “common ‘language’ and perspective with which those involved in projects both inside and outside of the company can develop IIoT products and services,” says Daigo Yoshii, who works alongside Josh to promote the use of TIRA, explains, “When you’re bringing together all this expertise to try to come up with a meaningful proposal, it’s very important that you all agree on the ‘words’ and perspective for discussing the various concepts and technologies involved in IIoT, so that you’re able to come to a common understanding on viewpoints and mindsets. TIRA is, essentially, a common language and perspective that we use when co-creating IIoT products and services.”

Daigo Yoshii, Expert, Strategic Planning Department, Planning Office, Digital Innovation Technology Center, Toshiba Corporation

He continues, “Unlike with things you can physically see, it’s not easy to get everyone on the same page about how to collect, manage, analyze, and process data. Figuring out what kind of service we want to develop and operate based on the data that’s analyzed is another important point of discussion. Having this shared perspective we can use to discuss these various points is very effective in working together on an IIoT project,

For example, let’s say Division A and Division B are working together to develop an IIoT service. A’s strength is in database construction, and B’s strength is in data analysis technologies. TIRA in this scenario would be the perspective that shows how these different technologies would relate to each other within the service they’re developing. Whenever you discuss something you can’t physically see, you have to first go through the tedious work of making sure everyone’s speaking the same language. TIRA makes that process much more efficient, and allows everyone to enter the discussions from the same perspective, so that they can get to the meat of the project more quickly.”

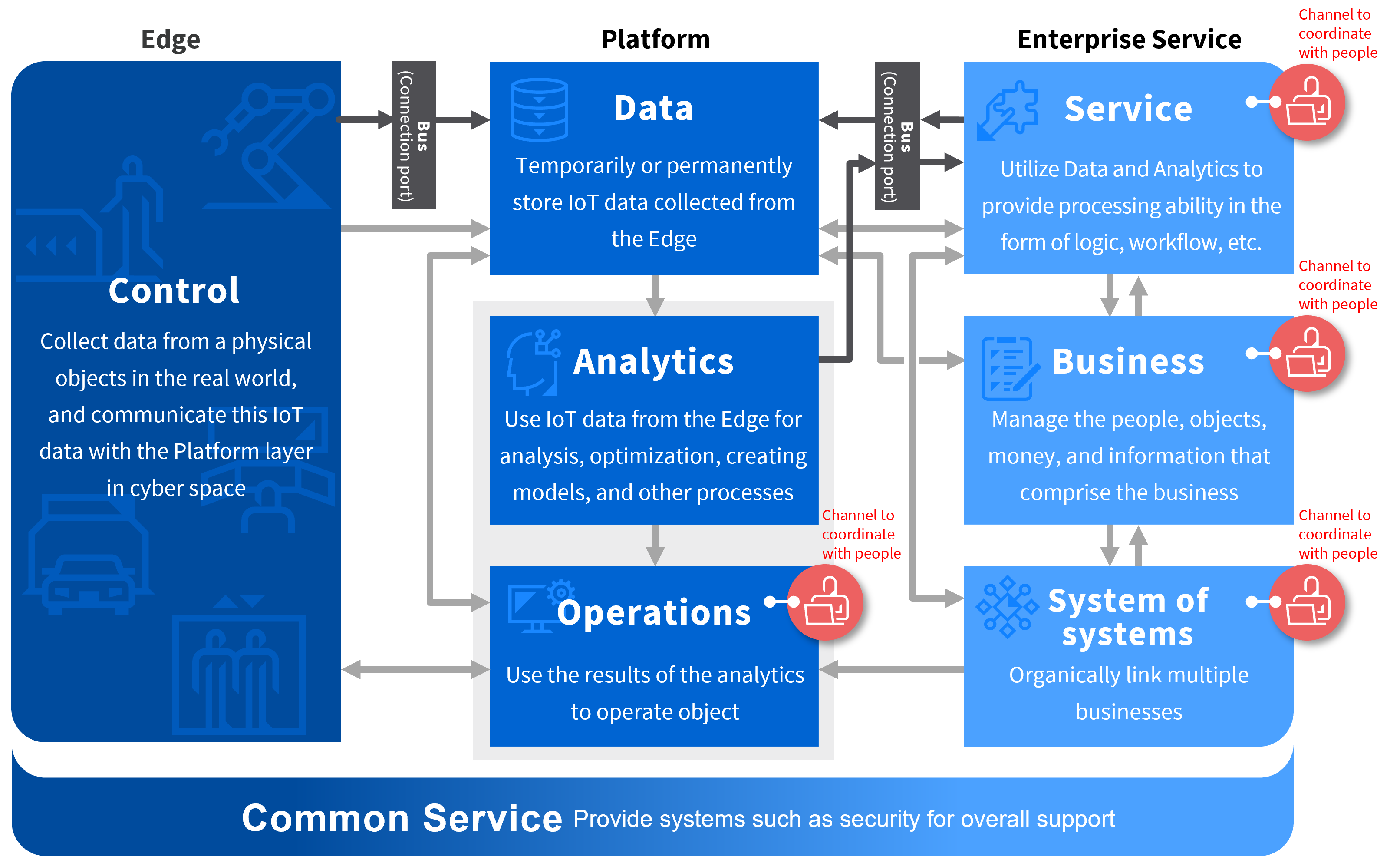

TIRA diagram

The diagram above makes it easier to understand how it actually works. TIRA is comprised of three layers, a control layer, platform layer, and enterprise service layer, as well as a common service that supports the entire system through security and other shared technologies. Seven categories, among them control, data, and services, exist within this system, with the diagram depicting how they relate to one another. There is also what are called buses, connection ports, that link the layers together. These can be used in standard ways to connect the system not only to Toshiba hardware and services, but to those from other companies as well.

Daigo says about TIRA, “The world is becoming more and more data-connected, and the connections are becoming deeper, thicker, denser. This strategy of going beyond just the company itself to co-create with products, technologies, and services from other companies, is only possible because we have this perspective in TIRA. What we’re doing now is creating a system that will be able to produce high-value, high-quality software and services in an efficient and continuous way, much like creating objects in a factory.”

Another thing that sets TIRA apart is Toshiba’s strength as a manufacturing company, specifically in hardware.

Josh discusses Toshiba’s need to take advantage of its hardware, saying, “Toshiba has about 150 years of experience and expertise in the manufacturing industry, and is very good at developing, implementing, and operating hardware. The data that’s collected in IIoT is analyzed in cyber space, but it’s hardware that feeds the results of these analyses back into the real world. In that sense, I’d say hardware is the ‘last one mile’ in terms of really, fully utilizing data. That’s what sets Toshiba apart from other companies, and what our focus is on that realm.”

Toshiba’s hardware expertise in the real world is what will allow it to fully harness the power of data

What Toshiba is working towards now is international standardization. Already, TIRA has been established as a standard in the previously-mentioned U.S.-based organization, IIC. Josh says, “International standardization will mean more companies that will be able to interface easily with TIRA, which will allow us to create new value on an exponential level. It’ll also be a way for Toshiba to contribute to the world by sharing our expertise, all while boosting our visibility on the world stage. That in turn will enhance Toshiba’s ability to deliver valuable products and services in a major way.”

TOSHIBA SPINEX service, having a ‘last one mile’ hardware advantage

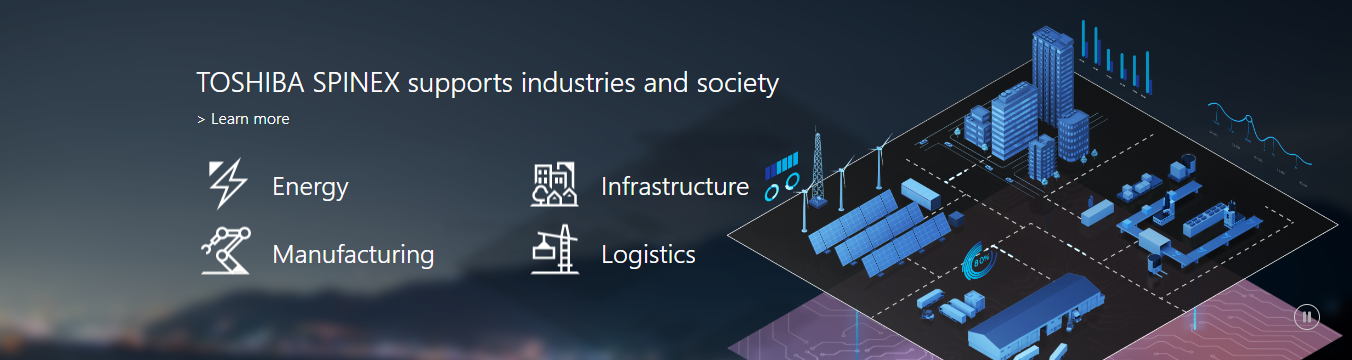

TOSHIBA SPINEX is a collection of services built on top of the TIRA architecture that is already creating value in society. These services, currently, mainly for the areas of energy, manufacturing, infrastructure, and logistics, are capable of collecting data from equipment and facilities, and accumulating, visualizing, analyzing, and even utilizing this data.

TOSHIBA SPINEX is a service currently offered primarily in the areas of energy, manufacturing, infrastructure, and logistics

“SPINEX is a reference to the spine. It was named that way because we wanted it to be something that would support society and provide value. Our hope is that it’ll connect to various other services and products, much like how nerves extend out from the spine,” says Josh. TOSHIBA SPINEX is currently being offered in 24 different forms in four areas.

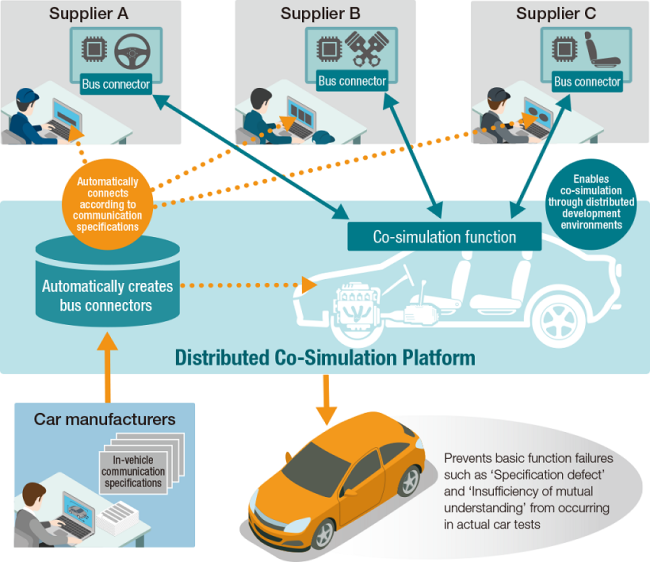

Daigo describes a typical use case. “Take, for instance, the simulation platform that’s used in the car industry to create virtual prototypes in cyber space. Different companies design their own parts, that will compose a single car all together. Before manufacturing the designs into physical parts, they can feed the designs themselves, as known as models, into the platform through buses (connection port) and linked in a standardized way, and simulate their integration as the single car in cyberspace, which should dramatically boost quality and productivity of the manufacturing of the car.”

TOSHIBA SPINEX allows car manufacturers to create virtual prototypes in cyber space

Despite TOSHIBA SPINEX’s expansion into a variety of industries and business categories, Daigo says in frank terms, “TIRA and TOSHIBA SPINEX are still not very well recognized around the world. Toshiba hadn’t even really been recognized as a player in the IIoT area in the global market, which meant nobody really saw us as being on the same playing field as other leading companies in the area.” He went on, however, saying confidently, “But by coming out with TIRA and TOSHIBA SPINEX, and establishing clearly the stance we want to take on IIoT, I feel we’ve finally managed to make it onto that playing field. I think now, we’re ready to catch up to them, and win.”

Josh describes Toshiba’s current circumstances using the analogy of a car manufacturer.

“The car manufacturers that offer a full range of vehicles are strong players with a solid position in the market. In contrast, however, there are also car manufacturers that pursue a completely different strategy, touting—for instance—distinctive engines or designs, or perhaps even just the joy of driving.

With these manufacturers, you hear the manufacturer name and immediately know the kind of car they make. We’re doing the same. Instead of taking on the giants head-on, we want to make clear what our perspective, our strength is. And architecture and service of this perspective, this strength, has been TIRA and TOSHIBA SPINEX.”

Finally, Daigo and Josh discussed the future they see for TIRA and TOSHIBA SPINEX.

“Toshiba’s goal is to use TIRA and TOSHIBA SPINEX to break through the ‘barriers’ of co-creation both internally and externally, and get even better at creating new value. Of course, there’s also rationality in doing things the conventional way. There’s a lot of expertise that’s accumulated in these methods, and within a certain scope it’s the most rational way to get things done. And of course, any new approach that greatly expands this scope will impose a new and tremendous burden on the company. There’s a lack of expertise there, and the future is uncertain. But I believe that these new approaches are more likely to help us catch up to and potentially even win against our competitors. What I want to see—along with everyone at the company—is a future where Toshiba has broken through these barriers, and come out so much stronger,” says Daigo.

“Whatever kind of world the future holds in store, Toshiba will remain true to its ultimate goal—delivering value to its end users. There’s still so much we have to do as a hardware manufacturer to feed the value that’s created from these data-harnessing services into the real world.” says Josh. “To do that, we’ll ensure that there are forums for open discussion on these various technologies both internally and externally.”

*1 Toshiba IoT Reference Architecture

*2 System where things, previously not connected to the Internet, are connected to servers and cloud services to exchange information.

*3 Industry IoT Consortium: International organization established in 2014 to help implement and standardize industrial IoT technologies

—

In light of the global trend of “standardization,” the thought leadership activities to introduce TIRA and TOSHIBA SPINEX to major influencers such as industry analysts and industry groups are described in “Standing out through thought leadership and global co-creation towards global co-creation -Efforts sustainability and See technology standardization.”

![]()

Related Links

*This section contains links to websites operated by companies and organizations other than Toshiba Corporation.

TOSHIBA SPINEX Marketplace