Keeping Geothermal Power Plants Running Trouble-free – Toshiba Takes on the Challenge of Increasing the Use of Renewable Energy

2024/04/25 Toshiba Clip Team

- Geothermal power generation, a renewable energy source, is gaining attention for carbon neutrality

- Using digital technology to diagnose signs of trouble in geothermal power plants?

- What is renewable energy DX led by both hardware and software expertise?

The abnormal weather caused by global warming, such as heavy rain, threatens our daily lives. Therefore, it has been a long time since the whole society has tried to reduce the emissions of greenhouse gases such as CO2 and aim for carbon neutrality. However, many readers may not have a clear idea of how our lives will change in this process.

For example, how do we use electricity that is produced in different ways? To achieve carbon neutrality, we need to increase the use of renewable energy (RE) derived from natural sources. This is because RE does not emit CO2 when generating electricity. However, RE has a weakness, and it is not as simple as just increasing it. The biggest weakness is that it is unstable. Variable RE such as solar and wind power depends on the natural conditions at the time, and it is difficult to expect those type of RE to supply power stably. As a result, unexpected power blackout may occur and affect our lives.

Therefore, the concept of “energy mix” becomes important. This is a method of supplying electricity by combining various power generation methods, such as hydro, solar, wind, geothermal, thermal, and nuclear. By utilizing the strengths and compensating for the weaknesses of each method, we can supply electricity stably while reducing CO2 emissions. The Japanese government’s “6th strategic Energy Plan” in 2021 also advocates the energy mix, and proposes an ambitious plan to increase RE to nearly 40% of the total.

RE constitutes around 40% of all energy under the Japanese government’s strategic energy plan

This time, we focus on geothermal power generation among RE. It is being developed in countries located in volcanic zones, such as the United States, Indonesia, and Japan, but there are some challenges for full-scale introduction and popularization. To solve these challenges, we asked engineers and salesperson to talk about the project that utilizes the knowledge of both hardware such as generating equipment and the power of digital.

The potential of promising renewable energy source of geothermal power generation?

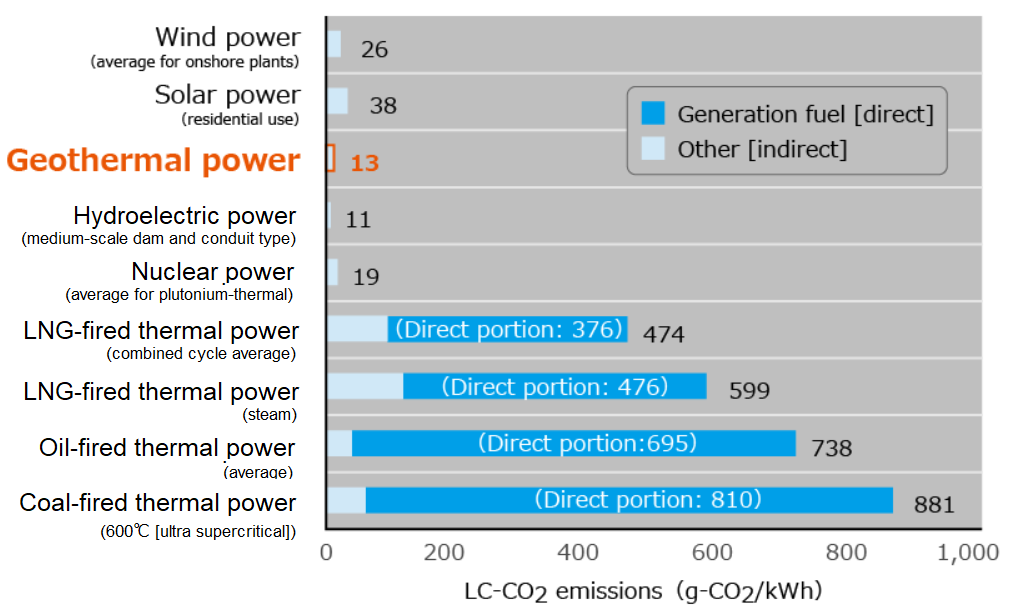

Geothermal power generation is RE that uses the heat of the earth, as the name suggests. Rainwater that seeps into the ground is heated by magma deep underground and becomes steam. Geothermal power generation uses this steam to rotate a turbine generator and produce electricity. The heat of magma is almost permanent. And rainfall is also repeated. This is why geothermal energy is expected as an energy source that can be supplied permanently. In addition, it is a power generation method that can contribute to carbon neutrality because it does not use fossil fuels and emits very little CO2.

As with other sources of RE, CO2 emissions from geothermal power generation are extremely low.

As the introduction of RE progresses toward carbon neutrality, low-cost and stable power sources that can generate electricity regardless of day and night have a large presence. Geothermal power generation is one of them, but how much expectation is there for geothermal power generation and what are the current challenges? We asked Ms. Mogi, who is in charge of sales at Toshiba Energy Systems, about the situation.

“Geothermal power generation is being developed in countries located in the Pacific Rim volcanic zone. Geothermal resources are exposed in volcanic zones, and the amount of resources is dominated by the United States, Indonesia, and Japan. However, we have not been able to fully utilize the potential of geothermal resources because of the challenges such as the risk of unsuccessful drilling, the time and cost required for geothermal resource exploration, and the various protection regulations such as the Natural Parks Law and the Hot Springs Law that make it difficult to construct power plants.

In addition, there are also challenges for existing geothermal power plants. It is difficult to secure and maintain the amount of geothermal steam generated from the ground, and it tends to decrease and deteriorate. In addition, the steam components contain sulfur and other substances that cause corrosion and deposition to equipment, resulting in deterioration of major equipment such as turbine generators. As a result, the power generation has to be stopped every time the equipment is in maintenance, and the calendar day utilization rate *1 is about 60%. How to improve the utilization rate of geothermal power plants is also an urgent issue.” (Ms. Mogi)

*1 The ratio of the actual power generation amount to the power generation amount that would be obtained

if the target power generation equipment were to generate electricity at 100% output for a certain period of time.

Chiaki Mogi, Deputy Manager, Global Marketing & Sales Office Business Development Dept.2 Group 5

Toshiba Energy Systems & Solutions Corporation

Toshiba has accumulated technologies and expertise in this field since it delivered a turbine generator to the Matsukawa Geothermal Power Plant, Japan’s first full-scale geothermal power plant, in 1966. As of July 2023, it has installed a total of 63 units with a total output of about 4GW (gigawatts), maintaining a world-class share. The challenges of existing geothermal power generation were “how to prevent the deterioration of turbine generators” and “how to increase the utilization rate of power plants”. How to solve these challenges? Mr. Ichikawa, who has been involved in the control technology of thermal power generation and geothermal power generation since joining the company, explains.

“Toshiba has developed a “super rotor technology” to cope with the deterioration of turbine generators. This is a technique to devise the material and coating of the turbine and make it resistant to corrosive components. The power plants that have introduced this technology have been able to operate without maintenance for more than 10 years, and there is no significant performance degradation due to corrosion. In other words, we have been able to improve the reliability of the hardware of the turbine generator.

In addition, we are creating value by utilizing IoT *2 and AI in the digital field. We realize the further improvement of the utilization rate of power plants by using the plant monitoring software EtaPROTM. Toshiba is able to utilize both the knowledge of hardware and software. That is our strength.” (Mr. Ichikawa)

*2 Internet of Things: A system that connects various devices and machines to the Internet and enables data exchange

and control.

What is EtaPROTM, which Mr. Ichikawa mentioned? Let’s take a closer look at it.

Hiroyuki Ichikawa, Fellow, Power Systems Div. Electrical System Engineering Dept.,

Toshiba Energy Systems & Solutions Corporation

Increasing Utilization Rates of Geothermal Power Plants through IoT and AI Implementation

Toshiba has developed a “Trouble Predictive Diagnosis Technology” for power plants by combining IoT (Internet of Things) and AI (Artificial Intelligence) technologies. This technology aims to improve the utilization rate of geothermal power plants as part of a national project by NEDO*3.

*3 New Energy and Industrial Technology Development Organization: A national research and development agency

that promotes the development and introduction of new energy and energy conservation technologies.

Specifically, they utilize the plant monitoring software called “EtaPROTM“. EtaPROTM collects various data from sensors installed to each facility within the power plant. Using AI, it compares the expected operational state (based on historical data) with the current measured values. By doing so, it detects signs of anomalies or declining utilization rates. This real-time monitoring allows for early detection of potential issues, leading to reduced plant downtime and improved efficiency.

The ultimate goal is stable electricity supply through geothermal power, expanded adoption of geothermal energy, and a path toward carbon neutrality.

How the warning signs of trouble are detected

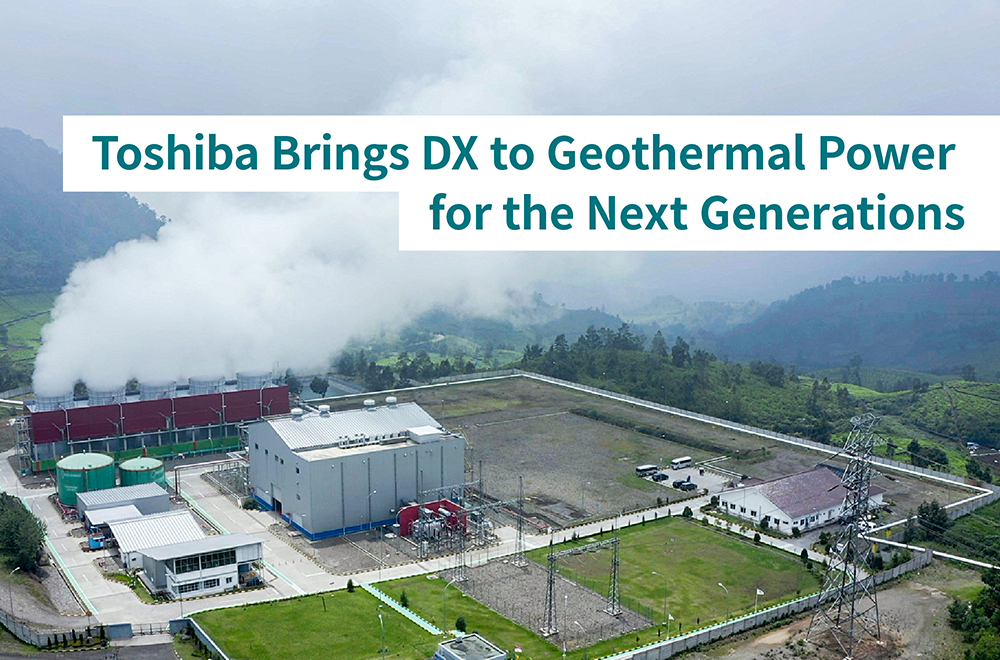

Ms. Mogi and Mr. Ichikawa’s activities have expanded beyond Japan. A feasibility study got underway in Indonesia in 2019, and it resulted in an evolution that delivered a next-generation power plant able to detect trouble with electricity-generating facilities using EtaPROTM. Ms. Mogi, who works closely with the customer, tells us more about the background.

“The demonstration experiment was conducted at Patuha geothermal power plant of PT Geo Dipa Energi (GDE), a state-owned geothermal power generation company in Indonesia. We deployed EtaPROTM on the power generation equipment to verify whether it could actually detect signs of anomalies and improve utilization rate.The results were impressive. A 20% reduction in trouble occurrence and a 2% increase in utilization rates. As a result, stable power supply strengthened, and GDE received recognition from the Indonesian government.

Indonesia has set a goal under the Paris Agreement to reduce greenhouse gas emissions by 29% by 2030 and aims for carbon neutrality. Toshiba has supplied turbine generator to the Patuha Geothermal Power Plant, and they have maintained ongoing communication with GDE (Geothermal Development Company) regarding maintenance support after the plant was put into operation. Amidst these efforts, the utilization of EtaPROTM by Toshiba has led to the successful achievement of the desired outcomes. Even after the demonstration experiment, GDE continues to use EtaPROTM and has expressed satisfaction with the service. Furthermore, based on this achievement, similar requests have been received from other countries.” (Ms. Mogi)

EtaPROTM monitoring screen

In fact, Mr. Andisyah Purdanto from GDE has evaluated Toshiba’s technology as follows:

“In our pursuit of enhancing reliability, availability, and efficiency, Asset Performance Management is deemed essential. GDE is currently in the process of developing tools for the implementation of Asset Performance Monitoring. Therefore, to bring our process for developing asset management tools we have chosen EtaPROTM because of some features including performance monitoring, data analysis, equipment failure prediction, and energy efficiency enhancement. We believe by using EtaPROTM, it can enhance our equipment operational performance maintain reliability and reduce cost.

The support of experienced Toshiba engineers in power plant analysis has been a significant factor in our decision-making process. Utilizing EtaPROTM, the real-time monitoring of equipment conditions directly from Toshiba’s headquarters has proven invaluable to us. This feature is particularly beneficial as we face limitations in the number of on-site engineers availability.

Toshiba’s fast response and comprehensive performance reports have greatly facilitated our ability to address issues and enhance operational efficiency and reliability. Toshiba extends full support regarding equipment knowledge, root cause failure analysis, spare part availability, and technical advisory services.”

Andisyah Purdanto, Maintenance Manager at GDE.

Toshiba’s DX with expertise in both hardware and software.

Toshiba, with expertise in both hardware (physical) and software (cyber), has made significant strides in digital transformation (DX). Notably, their software, EtaPROTM, originally developed for thermal power plants, was adapted for use in geothermal power plants—a pioneering endeavor. During the initial experiment, challenges arose in detecting trouble premonitions, leading to the realization that new development was necessary. Mr. Ichikawa, well-versed in both thermal and geothermal power, draws an analogy to driving a car to explain how they overcame these barriers.

“Thermal power plants operate under stable conditions, akin to driving at a constant speed on a highway. The difference between expected operational state (based on historical data) and current measured values is easily discernible through data. In contrast, geothermal power, influenced by the state of steam heated by magma, exhibits greater volatility in steam conditions compared to thermal power. As a result, determining abnormal values becomes more challenging.However, our accumulated knowledge and data from supplying equipment to both thermal and geothermal power plants proved invaluable. We reconstructed databases and software, accounting for the ‘data noise’ inherent in geothermal power. Leveraging our hardware insights, we successfully developed meaningful software—EtaPROTM.” (Mr. Ichikawa)

As mentioned earlier, the pilot experiment concluded successfully. GDE’s representatives expressed enthusiasm, calling the trial their “New User Experience.” EtaPROTM‘s ability to detect trouble premonitions and contribute to improved utilization rates was evident. The utilization of IoT and AI facilitated groundbreaking advancements in power plant operations—a true manifestation of DX.

The impact of this experiment extends beyond trouble detection. If remote monitoring evolves into remote control of power plants, further efficiency gains—such as reduced operational burdens and advanced data analytics—become visible. Mr. Ichikawa and Ms. Mogi, from their respective technical and sales perspectives, focus on the bright future that geothermal power promises.

“The data collected from the Patuha geothermal power plant was monitored and analyzed by both GDE’s headquarters in Jakarta and Toshiba in Tokyo. This signifies that Toshiba can offer consulting services for power plant operations, including equipment optimization, toward reducing greenhouse gas emissions. Naturally, the data obtained will also inform improvements to turbine equipment as hardware. By synergizing hardware and software, we can contribute to carbon neutrality.” (Mr. Ichikawa)

Engineers perform remote monitoring from Japan (for illustrative purposes)

“Stabilizing geothermal power plant operations and increasing utilization rates directly aligns with carbon neutrality. Looking ahead, we envision climate change solutions. As a mother, I contemplate the world our children will inherit and discuss sustainable solutions within our team. We hope our efforts play a part in shaping that future.” (Ms. Mogi)

![]()