Power Semiconductors Support a Once-in-a-Century Revolution in Automobiles

2024/07/11 Toshiba Clip Team

- Power semiconductors are at the center of the two-fold electrification of cars.

- The front line in the continuing evolution of power semiconductors.

- Simulation support technology sharply shortens vehicle development time.

As we experience more sudden heavy rains, intensifying typhoons and hurricanes, and extended, ever hotter heat waves, climate change is bringing drastic changes to our daily lives. The cause lies in the buildup of CO2 and other greenhouse gases in the atmosphere, raising global temperatures, and is one of the main reasons why so much attention is being paid to the two-fold electrification of automobiles: first, the transition to electricity to power vehicles, ending reliance on combustion engines that burn gasoline and emit CO2; second, the electrification of on-board systems, power steering and functions to improve their performance efficiency, reliability and safety.

Power semiconductors that regulate electricity flows are absolutely essential for this electrification—and it’s an area where Toshiba continues to lead the way in product development and manufacture. What is Toshiba now working on, and what kind of value will the company deliver in the growing power semiconductor market? This article introduces the latest developments in power semiconductors, including silicon and next-generation power semiconductors, and Toshiba’s efforts to support efficient vehicle development.

The real value of power semiconductors, the heart and muscles of any vehicle

With the growing impact of climate change and concerns to reduce emissions of CO2 and other greenhouse gases, the concept of what is a vehicle is also being reconsidered. Just how important this question is can be seen in that fact that emissions from the transportation sector, including automobiles, account for 17.4% of Japan’s CO2. The electrification of vehicles is producing various flavors: electric vehicles, aka battery electric vehicles (EV/BEV), that run 100% on electricity; hybrid vehicles (HV/HEV) and plug-in hybrid vehicles (PHV/PHEV) that use both gasoline and electricity; and fuel-cell vehicles (FCV/FCEV) that use hydrogen to generate electricity. Collectively, they are referred to as xEV. Regardless of whether the vehicle is an xEV or gasoline powered, electrification of on-board functions to improve their performance efficiency, reliability and safety is also progressing. As more cars are powered by electricity and use electronics to deliver useful functions, it is only natural that the power semiconductors that control electricity flow should also evolve.

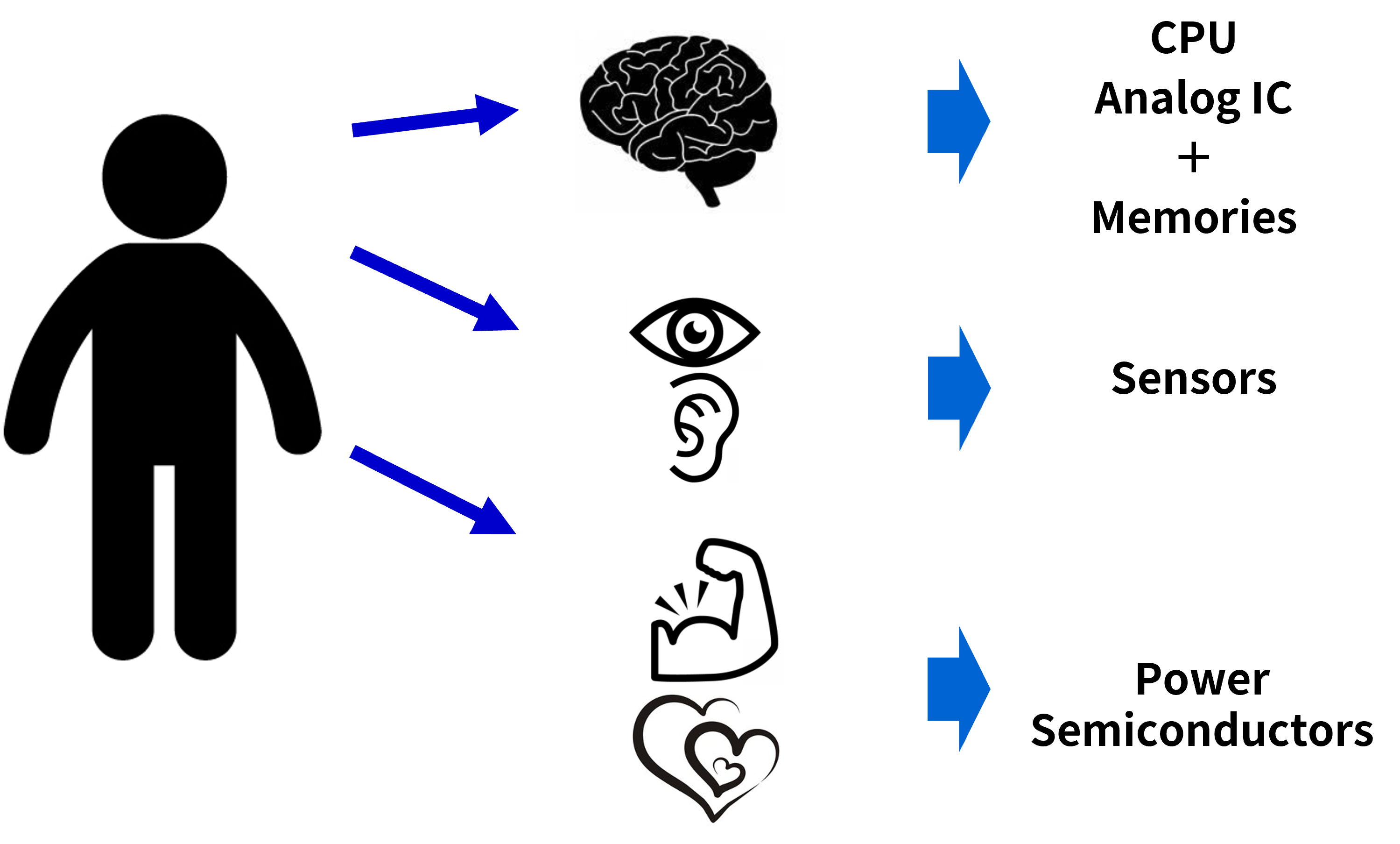

To get an idea of where power semiconductors are used in cars, and the role they play, it’s useful to make a comparison with the human body. In a car the processors, analog ICs, and memories that perform calculations are the brain; the sensors that monitor external conditions, speed, and current location for safety purposes are the eyes and ears. Power semiconductors are the heart and muscles.

In vehicles, power semiconductors play the role of the heart and muscles

In an xEV, the power source is an electric motor rather than a combustion engine that burns gasoline. The gas tank is replaced by a battery that supplies power, and some xEV auxiliary utilize motor to generate electricity from the kinetic energy of rotation of the vehicle’s wheels when it slows down, aka regenerative braking. This is the point where power semiconductors step in, to control the power supply and voltage and turn the electric current on and off. The market is expanding fast, with annual growth in the automotive sector estimated at over 10% a year from 2022 to 2030. Current expansion is driven by the increasing use of electronic equipment that provide more useful functions, but the demand for power semiconductors will also grow as xEVs become more popular.

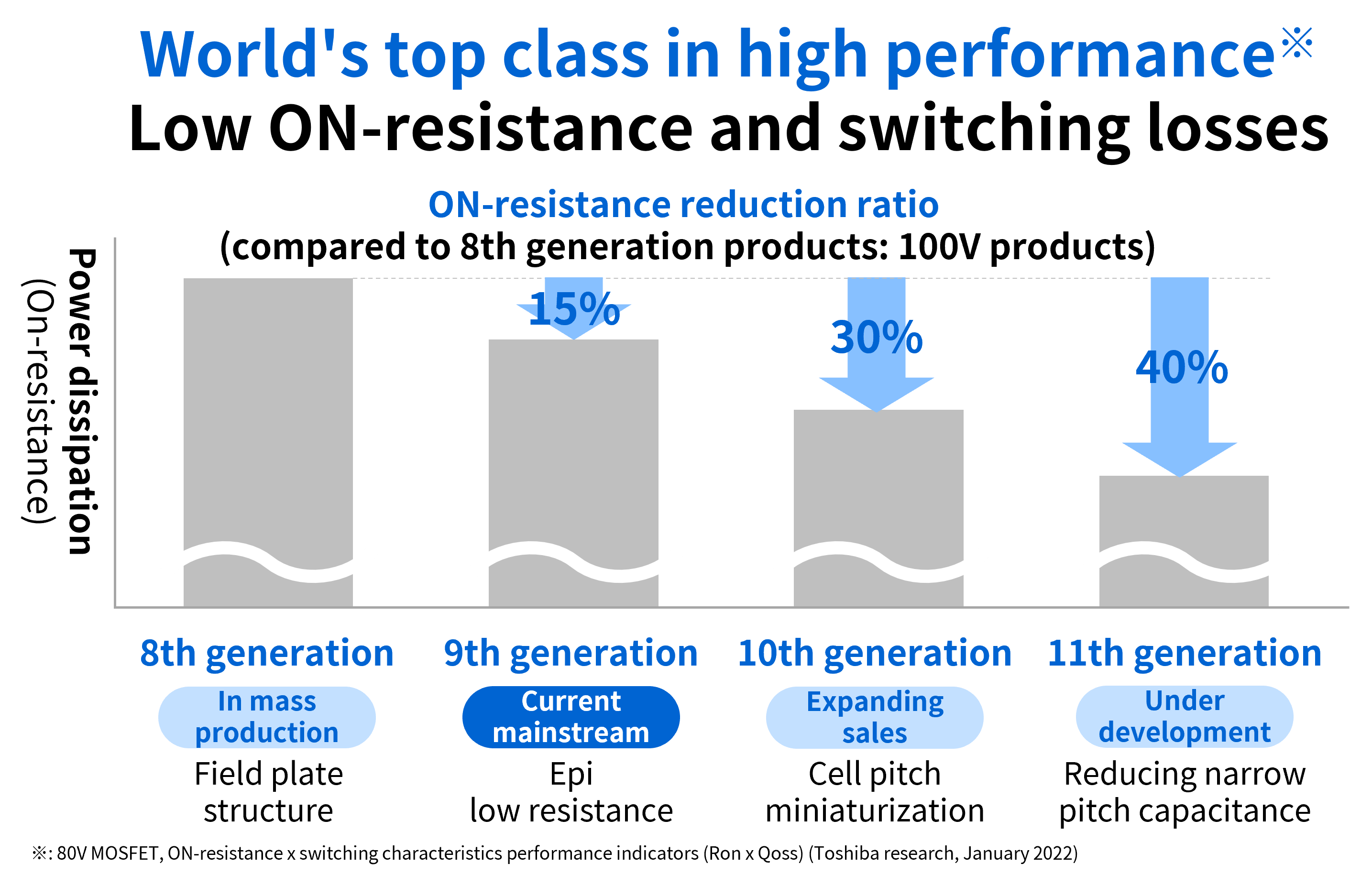

The larger electric current they can handle and the more frequency they turn it on and off, the more precise the control, the more reliable and comfortable our cars are. However, switching from on to off and back results in losses of electricity, switching loss, that is only increased by constant switching.

Toshiba delivers world-class high performance and is reducing switching loss

As the mobility sector evolves, power semiconductors come to the forefront

In its work to cut CO2 emissions with power semiconductors, Toshiba’s development work currently centers on Si-MOSFETs, silicon-based devices (Si). MOSFETs contribute to our lives in all sorts of ways—not only in the electrification of cars, but also in computers, home appliances, railway rolling stock, data centers and more.

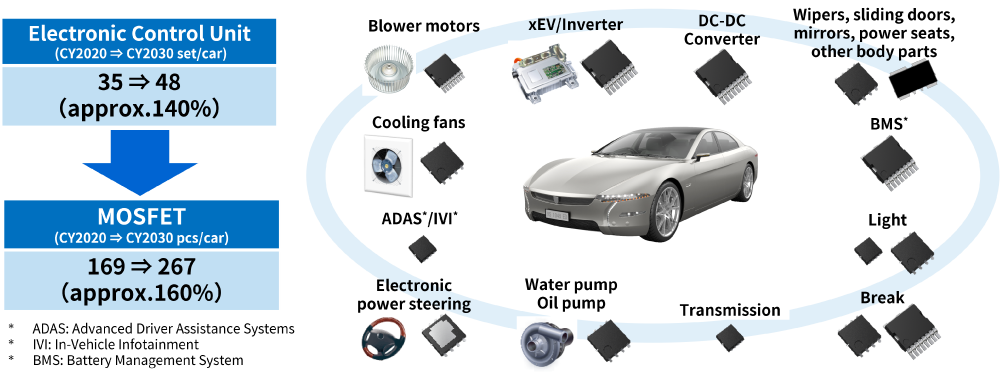

Power semiconductors are increasingly being used in automobiles.

The electrification of automobiles continues to advance. Toshiba’s research has found that, in 2020, a typical vehicle had 35 electronic control units to manage systems with electronic circuits, a number that will reach 48 by 2030, an increase of 40%. Alongside this, the number of MOSFETs in vehicles will jump from 169 to 267, a 60% rise.

The many power semiconductors installed in vehicles must be robust, able to resist the vibration and shock that comes with driving, and stable enough to work in a wide range of temperatures and humid conditions. Power semiconductors for general use need to be able to operate only at up to 150°C, but for use in automobiles they must withstand temperatures as high as 175°C, and meet the stringent requirement of an almost zero defect rate. Since any failure can directly impact on human lives, automotive components must be developed and implemented to meet the highest standards.

Toshiba’s research into silicon power semiconductors, a history of over 60 years, has given the company a rich cumulative base of technologies that it can bring to high-performance devices. For example, today, its lineup covers more than 500 products, including the U-MOS series of low voltage MOSFETs, which deliver the world’s top-class performance. The company is committed to ensuring stable supply, and securing this by further increasing production capacity and boosting productivity.

Toshiba is also focusing on future generations of power semiconductors, more efficient devices. Silicon carbide (SiC) is one major option, as it can manage higher voltages with lower resistance than silicon, a characteristic that contributes to higher output and efficiency, and smaller electronic devices. Achieving carbon neutrality means that xEVs must reduce CO2 emissions and extend their cruising range—if SiC semiconductors can reduce power consumption, CO2 emissions will be reduced, and so too will the size and weight of electronic equipment installed in vehicles. This will allow installation of a larger battery, which will extend the range.

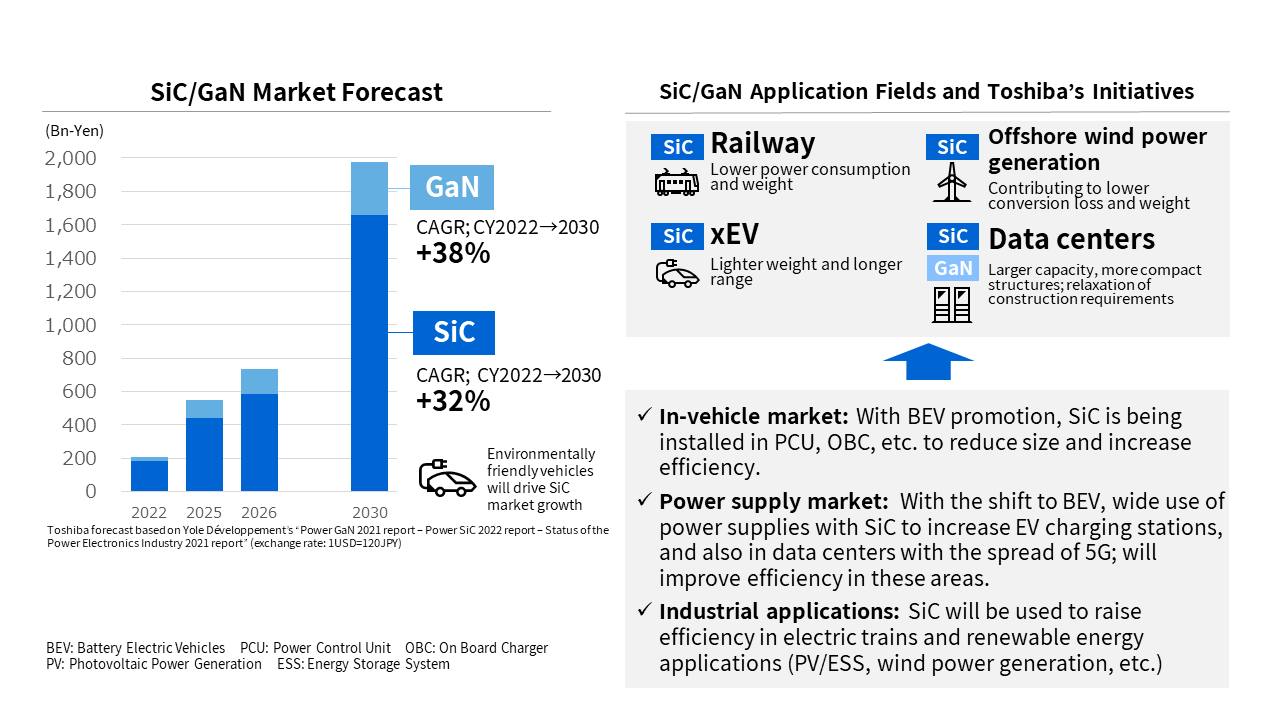

In addition to SiC, Toshiba is also developing next-generation power semiconductors fabricated with gallium nitride (GaN), research selected for support by the NEDO GI Fund1 SiC/GaN project. Future power semiconductors must continue to meet requirements for even higher output and increased efficiency that will allow us to put in place infrastructure—including xEVs, railways, and offshore wind power generation—that enrich and sustain our lives. Toshiba will continue to drive forward both quality (high performance) and quantity (production capacity) in coming generations of devices.

1 Green Innovation (GI) Fund of The New Energy and Industrial Technology Development Organization (NEDO), one of the largest public R&D management organizations in Japan, supports research in 14 priority fields.

Promotion of carbon neutrality is bringing next-generation power semiconductors into an increasing range of applications

What value to create toward realizing carbon neutrality?

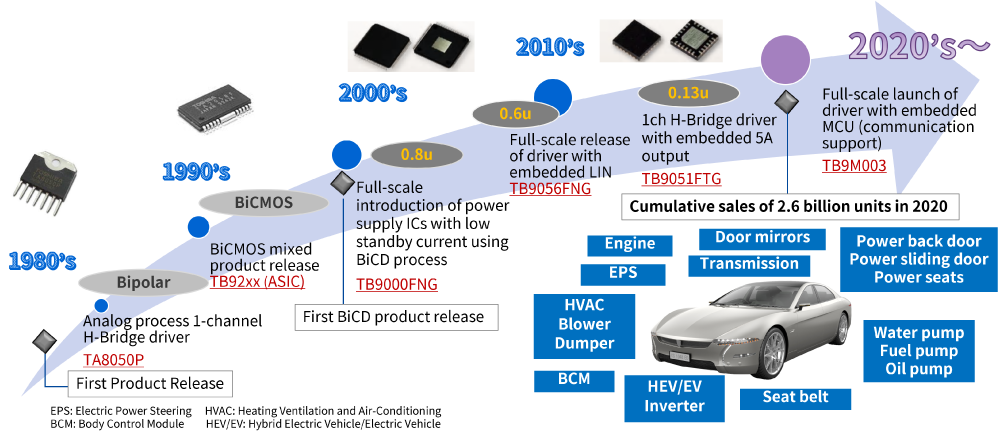

Power semiconductors, the heart and muscles of automobiles, are not the only area where Toshiba is contributing to the automotive sector. The company is also a major presence in analog ICs, and has produced over 2.6 billion devices since releasing its first products in the 1980s. Toshiba is particularly strong in motor applications, a crucial part of vehicle electrification, and another area where there is high demand for increased functionality and smaller size. “SmartMCD™,” which was released at the end of fiscal year 2023, meets these requirements in terms of miniaturization, low power consumption, and other aspects of carbon neutrality.

Toshiba has mass-produced 2.6 billion analog ICs in 46 years

Toshiba also has a presence in other areas, including model-based development (MBD), a product engineering methodology that makes full use of simulations. As electrification advances, vehicles carry more and more devices and sensors, which means software to be developed in parallel with vehicle development. Naturally enough, this increases the steps needed for coordination, development times becomes longer, and costs go up. MBD simulations realize timely confirmation of specifications at each stage of development. This prevents unwanted reworking.

One Toshiba contribution here is Accu-ROM™, a powerful technology that simulates heat and noise generated by power semiconductors. Which made simulation a customer took as long as 33 hours to model heat and noise, it can now be done in about 3 hours and 30 minutes. Toshiba will continue to support MBD and to help customers improve development efficiency.

As we have seen, Toshiba has accumulated tangible and intangible technological assets in automotive semiconductors, including power semiconductors. The company will draw on this knowhow as it works to understand the needs of its customers and society, increases production capacity and productivity, and continues to develop new products. In a period of rapid change in the mobility sector Toshiba is creating value, inspired by a strong determination to “turn on the promise of a new day” and achieve a carbon-neutral society. The company will continue to develop ambitious ideas and new products into the future.

Over the years, we have built up tangible and intangible technological assets in automotive semiconductors, including power semiconductors. We will draw on this knowhow as we work to understand the needs of our customers and society, increases production capacity and productivity, and continues to develop new products. In a period of rapid change in the mobility sector we are creating value, inspired by a strong determination to “turn on the promise of a new day” and achieve a carbon-neutral society. We will continue to develop ambitious ideas and new products into the future.

![]()