We are Toshiba: Pursuing Optimal Solutions for Devices Essential to Society -Application Engineers Turn on the Promise of a New Day, as a Bridge Between Customers and Product Development

2024/03/21 Toshiba Clip Team

- The true satisfaction of application engineering is understanding the needs of the market and using them to shape technologies.

- Never simply say no, communicate closely with customers to facilitate design and development.

- Bringing reliability to EVs and industrial equipment.

Application engineers have a lot on their plate: understanding customer needs, while keeping an eye on market trends; conceptualizing the kind of products that are needed in society; working with the design and development departments to turn them into reality; and taking customer feedback and incorporating it into the development of future products. They handle all of this and provide one stop solutions to customers who use electronic devices in their products.

Ke Leng is an application engineer in the Optical Isolation Application Engineering Department at Toshiba Electronic Devices & Storage. She works with photocouplers and digital isolators, devices that are important even on a societal level, given their role in realizing reliability in various products—including EVs in an automobile industry undergoing a once-in-a-century revolution, and industrial robots, now increasingly common with factory automation.

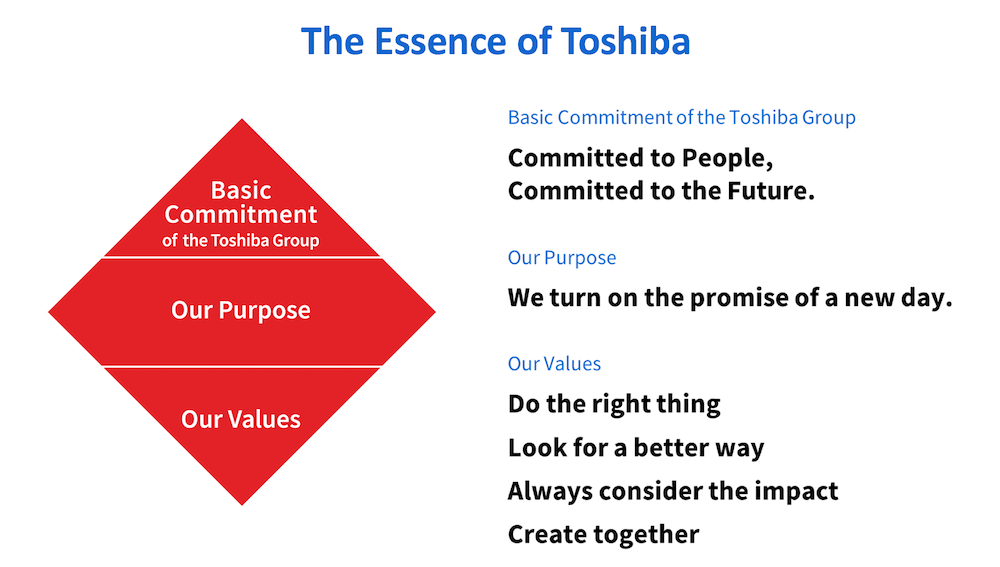

The “We are Toshiba” series follows the work of employees who embody Toshiba Group’s philosophy, the “Essence of Toshiba”, and its three elements: the “Basic Commitment of the Toshiba Group,” “Our Purpose” and “Our Values.” In this article we spoke to Leng, who every day explores customer needs and communicates with the design and development departments to figure out optimal solutions for each product. What does the future look like for these important devices, and how does application engineering drive their development and evolution?

Putting Both Knowledge of Technology and Communication Skills to Work

Leng studied programming and software development at university in China, and came to Japan to further her studies at a graduate school. She learned about the field of application engineering at Toshiba while exploring the career opportunities available to her, and found herself drawn to the idea.

“I learned software programming in both China and Japan. I wanted to use what I’d learned about technology while also communicating with others. Technology and communication are both important to me, and I knew that I wanted to practice both in my work.

“That was when I discovered the application engineering position at Toshiba Electronic Devices & Storage. The job would involve everything from product development to delivery, from asking customers about their needs to working with other departments on development. I was drawn to the position, and joined the company. I’d been looking at Chinese companies as well, but it was hard to find a company that covered as wide a range of areas as Toshiba.”

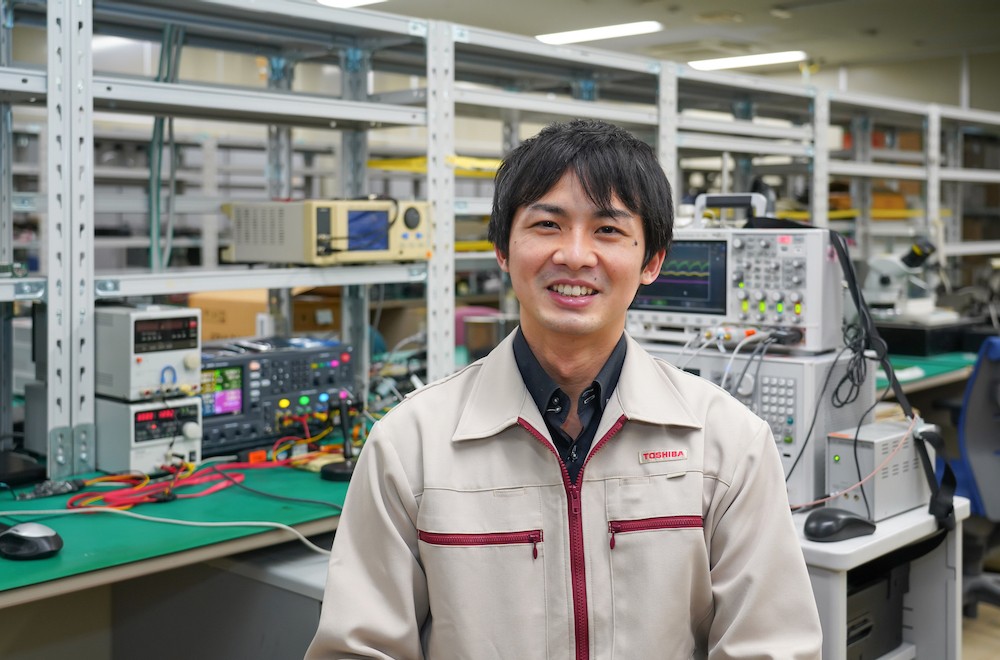

Ke Leng. Optical Isolation Application Engineering Group II, Optical Isolation Application Engineering Dept., Semiconductor Application Engineering Center, Toshiba Electronic Devices & Storage Corporation

Growing up in China, she was familiar with Toshiba, a popular manufacturer of consumer electronics during her childhood. Her interest in the company deepened as she began to view Toshiba Electronic Devices & Storage as a potential employer, and got to know more about its products and technological strategy. What caught her attention was the company’s product lineup—an assortment of devices that not only helps sustain our digital society, but also ensure the energy efficiency and reliability of a wide range of equipment.

“Toshiba has a high market share and a proven track record in the area of power devices,” says Leng “Semiconductors as small as a grain of rice are used in industrial robots and automobiles to control and convert power, helping to establish energy efficiency and reliability in all kinds of things out in society.

“Ever since joined the company, I’ve worked as an application engineer on photocouplers. They serve as isolators, and enhance product reliability. They number among the many devices that are essential to society, and it’s very rewarding to be able to support society like this, behind the scenes. Since starting the job, I’ve worked as hard as I can, thinking every day about the things I can accomplish as an application engineer.”

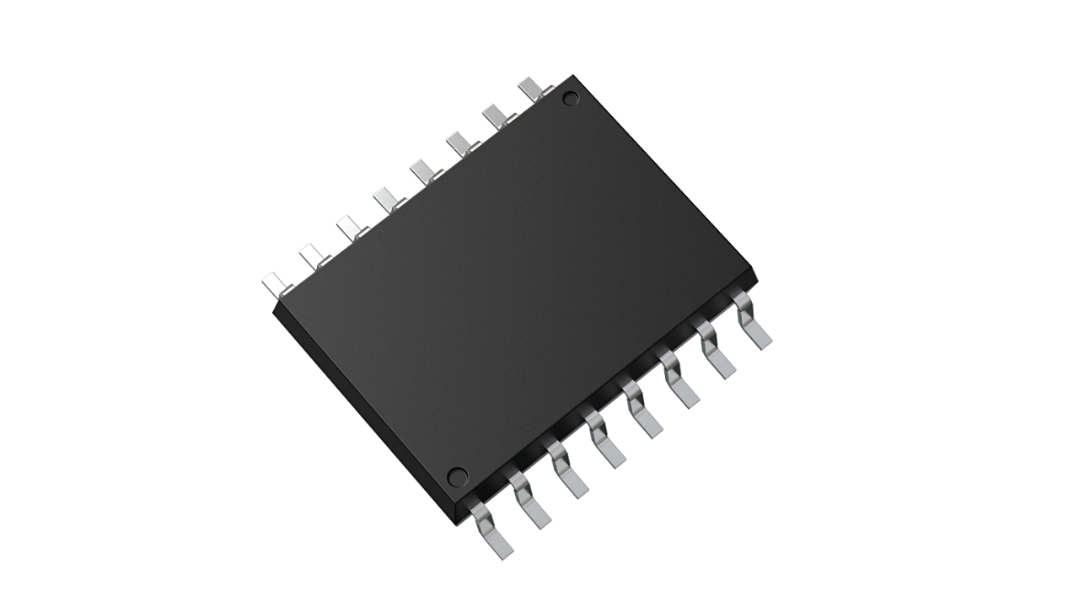

Photocouplers are devices that deliver signals in an electrically isolated state. Leng uses the analogy of using a TV remote to explain the device.

“A remote doesn’t use electricity to turn the TV on or change the channel. It uses an infrared light signal invisible to the human eye to turn switches on and off, and for various other operations. Photocouplers are similar, in that they also use light instead of electricity to transfer signals. Isolation in this case refers to a state in which there is no electrical connection. Using light instead of electricity ensures safety in various kinds of industrial equipment. For instance, in places where different voltages are at play, in sensitive equipment where static electricity from someone just touching the equipment could lead to problems, or in readiness for sudden voltage changes that result from a lightning strike.

“Besides photocouplers I also work with digital isolators, which isolate and serve as a bridge between two parts of an electronic circuit, using a magnetic field instead of using light. They’ve started to get a lot of attention in recent years. While these two devices already played an important role in society behind the scenes, the push for electrification, and ultimately for carbon neutrality, has caused demand to skyrocket. These are really devices that will shape our future.”

A photocoupler. They isolate devices, and prevent voltage shift that might result from static electricity from a person, or a lightning strike.

Never Just Say “No”: The Pride of an Application Engineer

How do photocouplers and digital isolators actually work? We can use an electric vehicle (EV) as an example. The power controller unit, motor, and inverter that power an EV operate at multiple different voltages. Coupling these directly may cause problems, both in terms of operation and safety. Photocouplers and other isolation technologies prevent direct electrical connections between the high-voltage motor and the low-voltage controller.

Toshiba Electronic Devices & Storage has the world’s largest share*1 of the photocoupler market, and also leads the industry in cutting-edge digital isolators. The company boasts cutting-edge device technology, a sophisticated development system, and the expertise to implement these technologies in ways that suit user needs. The role of Leng and the other application engineers is to bring these strengths together in order to create value.

“A lot of companies around the world that are researching and developing power devices and their peripherals,” says Leng. “I think Toshiba, as one of the very few companies that offer photocouplers and digital isolators, is at the very forefront of this development. We as application engineers work with the design and development teams to keep coming up with new products, so that we’re able to offer products, including of course photocouplers and digital isolators, that meet customer needs and are a step ahead of the pack.”

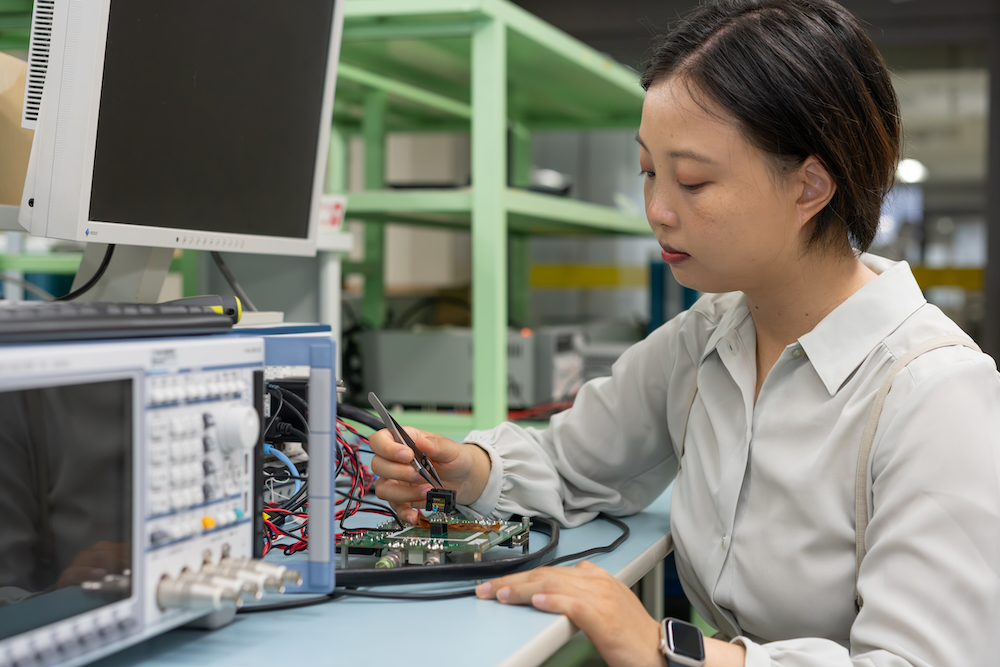

Leng evaluating a device to confirm it meets specifications defined in product planning

Application engineers play a demanding role. They ask customers about their needs, share the information with the application engineering team, and discuss performance requirements with the design and development departments. They also evaluate products to make sure they meet customer requirements as well as making sure they work in the set they are designed for, and then maintain responsibility for the rest of the product journey, all the way through to production.

Leng, now in her fourth year of work and in the photocoupler application engineering team, conducts product evaluations, facilitates communication with users, and offers support for points of contact between the engineering, design, and development teams. It is said that application engineers must be both engineers and salespeople, and Leng’s work seems to reflect exactly that. No wonder that application engineers are said to need the perspective of both an engineer and a salesperson.

“What we prioritize above all is not just saying ‘no’ to our customers,” says Leng. “As application engineers, we are in an important position, the bridge between the development department and the customer. If we say ‘No, we can’t do this,’ the business transaction ends right then and there.

“For instance, let’s say a customer asks for a device capable of handling two milliamperes. We go and speak with the development department, and they tell us that with these conditions and this budget, they can manage 1.9 milliamperes. The customer, of course, would like to procure a high-performance product at a low price, but the development department has their own thoughts about the extent to which they’ll be able to fulfill the customer’s demands. Our job as application engineers is to communicate these needs and these requirements with those involved, and negotiate so that we can decide on a product with the optimal performance.”

*1: Andrew Norwood et al. (March 31, 2023), Gartner®, “Market Share: Semiconductors by End Market, Worldwide, 2022” Revenue Basis, Photocoupler = Coupler

GARTNER is a registered trademark and service mark of Gartner Inc. and its affiliates in the U.S. and other countries, and is used under licensing by Gartner Inc. All rights reserved.

Developing Skills To Help the Company “Turn on the Promise of a New Day”

In some cases, when customers request numerous additional specification requirements, it can take several years for a final product to be delivered. Leng recalls that, while working to improve both her technological and sales abilities, she witnessed a senior employee present a solution to a customer that she felt was exactly in the spirit of application engineering.

Many users were interested in seeing a photocoupler that combined three distinct features, with further request for development at a certain level of target price. The design and development department came back and said it would be difficult to implement all three features at that price.

“My first thought when I heard that was, ‘Oh no, what do we do?’ I couldn’t figure out a way around it, but I wanted to make it work somehow. When we discussed the situation with the design and development teams, we learned that it was possible to implement two of the features—just not all three. At that point, it occurred to us that we could present the customer with three different products, each with two of the features they were asking for, and that became our solution as a team: if the features they were asking for were A, B, and C, we would propose three devices, the first with A and B, the second with B and C, and the third with A and C. I think that was one project where we saw the real value of application engineers refusing to say ‘no’ outright.”

Leng’s vision of application engineering is of a field that thrives during periods of change and the emergence of numerous new technologies, and that contributes to society in a meaningful way. One in which application engineers share their experience within the team, and their knowledge of technology, to come up with creative solutions.

“There are newer models of photocouplers on the market that do more than isolate—that, for instance, report malfunctions to the controller. If multifunctional devices like these become more advanced, we’ll get devices with fewer peripheral components. This will save space, and I’m sure pave the way for EVs and industrial equipment that are easier to design. It’s important that we try to foresee what the market will look like five, ten years from now, if we want to create the kind of products that users want, and that will become commonplace in society.”

Leng’s eyes lit up as she spoke about wanting to learn more about photocouplers and digital isolators, and, more broadly, about semiconductors in general. There is no end, it seems, to the knowledge that needs to be taken in, the specialized skills that must be honed.

“I go home to China sometimes, and over half of the cars on the streets there are already EVs. I think we’ll begin to see more and more of this throughout the world, and I want to begin to utilize this impression I have of the future in my actual product planning and proposal processes. To do that though, I’ll have to talk to a lot more customers, and hear directly from them about their needs. I’d like to visit China and other Asian countries, as well as Europe and the U.S., and talk to the users there. I want to learn more and build experience in a wider range of areas, in areas other than the industrial equipment-oriented semiconductors I’m currently working with—say, in automotive semiconductors. To do that, I’ll use the systems that are in place for employees to improve their skills and expertise, which include, for instance, going for a short stint to a different department in the Semiconductor Application Engineering Center, to study there.

My goal is to create an overlap between what customers want, and what Toshiba as a company wants to put forward as its strengths. There’s so much that I want to do and should do to accomplish this. What I need to do is tackle them one at a time, build up my experience. I think that’s exactly the sort of effort needed to realize Toshiba’s Purpose: ‘We turn on the promise of a new day.’”

As she furthers her studies and learns more about customer needs, Leng will come to see the society that lays beyond the products she proposes, a society supported by a wide range of equipment, from EVs to industrial robots, that utilizes the very products she has proposed.

![]()