Keeping the Community Safe from Crime. A System that Detects Dangerous Objects in less than a Second, Without Fail. -Introducing Toshiba’s millimeter wave radar technology

2024/12/13 Toshiba Clip Team

- A millimeter-wave radar, walk-through inspection system that accurately detects dangerous objects in less than a second without stopping people flows

- Sensor modularization allows configuration for locations and requirements

- Software defined approach supports customization to meet diverse customer needs

It is an all too familiar scene that plays out all too frequently of our TV screens. Once again, somewhere in the world, innocent bystanders are the victims of a violent attack. As often as not, the attackers choose soft targets where security is lax, such as large public gatherings or mass transit systems. Terrible as these attacks are, it is practically impossible to stop the movement of people or to carry out security inspections in public spaces.

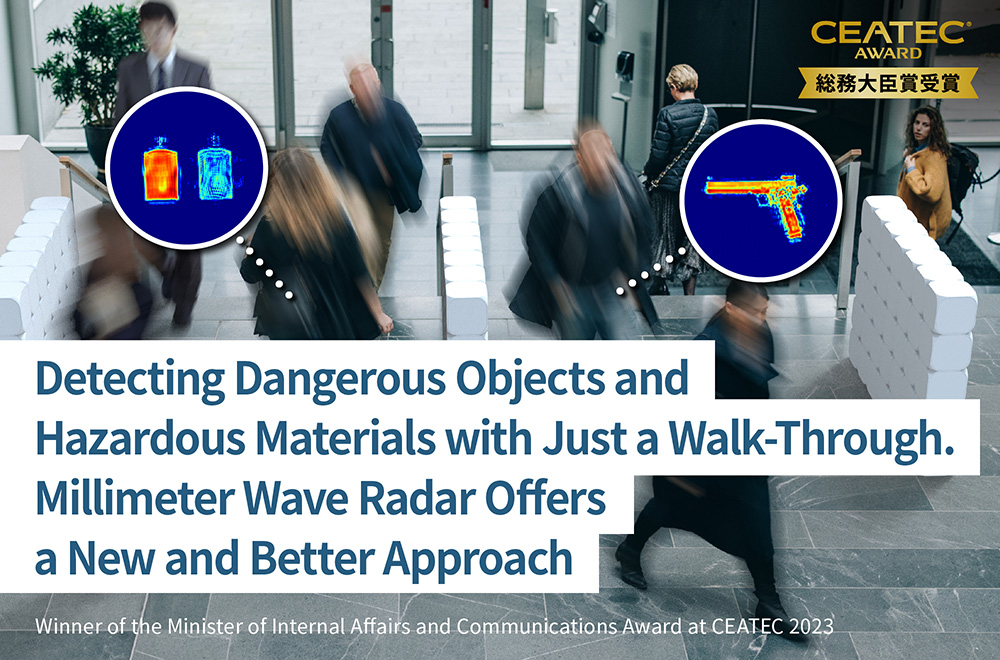

These concerns prompted Toshiba to develop its Millimeter Wave Radar Walkthrough Inspection System. In 2023, at Japan’s CEATEC, Asia’s largest IT and electronics exhibition, the system’s unprecedented value, including its speed, precision and a versatility that allows use in many locations, earned it the Minister of Internal Affairs and Communications Award. The two people who played central roles in the project talk about how the system was realized through close coordination of R&D and technological strategies, and about the spatial security management solution that the system aims to provide.

Meeting growing needs for security in public spaces

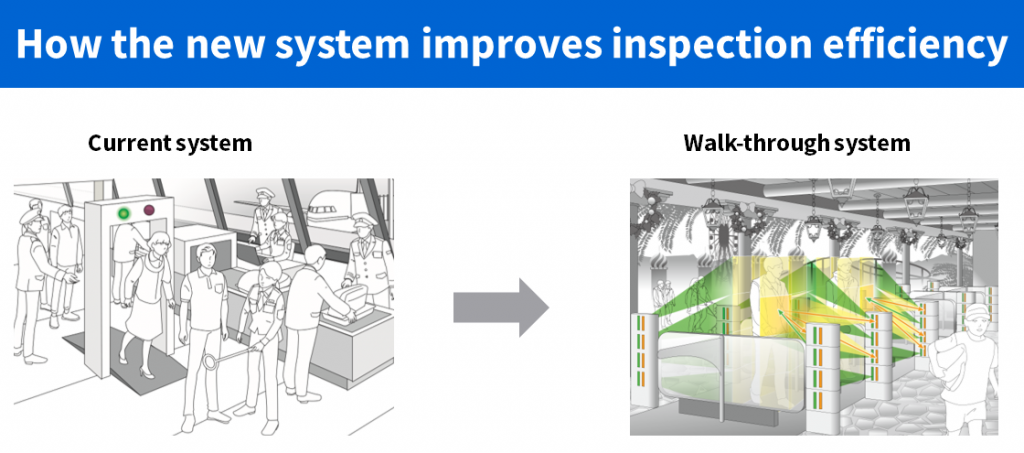

Surveillance cameras are increasingly deployed in response to concerns about crime and public safety, and while they help, there are still problems, particularly the impossibility of detecting weapons concealed in clothing. However, the use of metal detectors to bolster security checks at event venues is unrealistic, as they would stop flows of people in public spaces.

These public safety issues are behind Toshiba’s decision to develop a walk-through inspection system built around millimeter wave radar. It is a revolutionary system with high detection accuracy, but still flexible enough to be used in all kinds of spaces, including buildings, commercial facilities, and theme parks.

Hiroki Mori, the man behind development of the system, has given a lot of thought to public safety issues, and speak with a strong conviction. “Declines in working populations in many countries, including Japan, will make it increasingly difficult to hire security personnel,” he says. “But if you look at things like the recent rebound of inbound travel into Japan, it’s pretty clear that the need to ensure people’s safety and security will only increase. We were really aware of a need to maintain the convenience of public spaces by putting in place security systems that can detect suspicious objects quickly and reliably, as fast as possible.”

Instant inspections and highly accurate detection, two functions that are difficult to combine

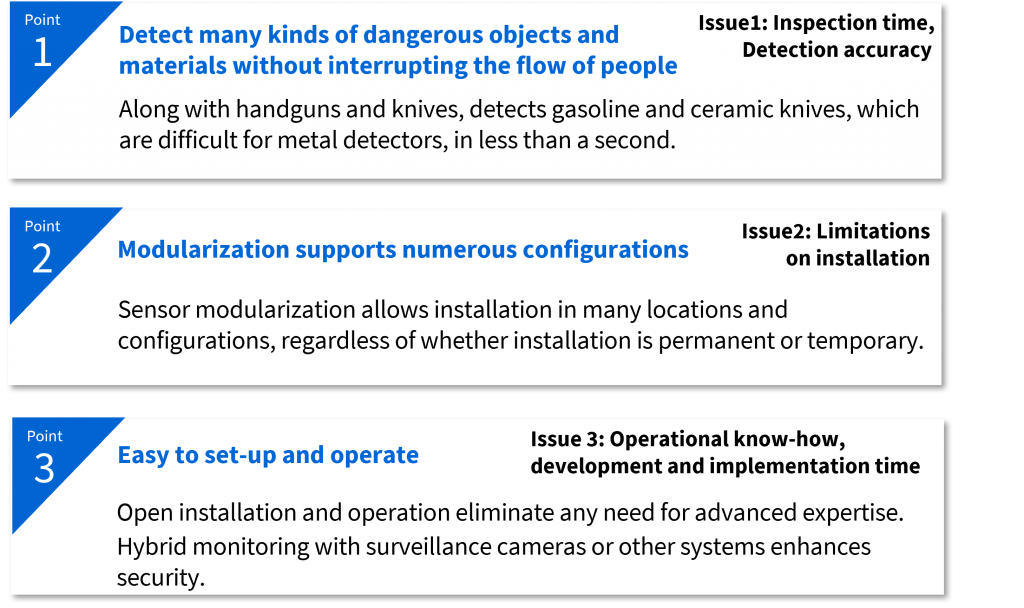

The inspection system has three important characteristics: highly accurate detection that can detect a wide range of dangerous object in under a second, with no interruption to the flow of people; modularization of sensors that supports configurations for specific environments and site characteristics; and ease of set-up and operation with no need for advanced technical knowledge. Let’s take a closer look at each of them.

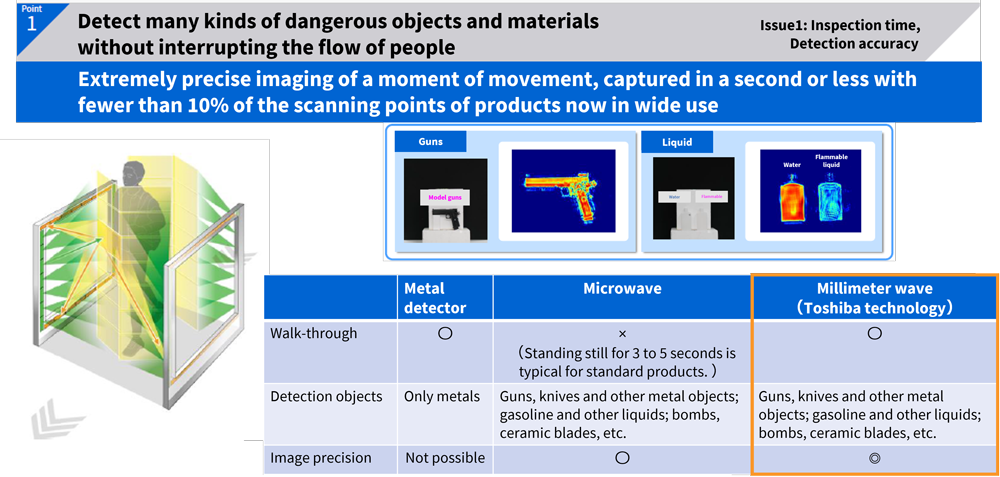

The first feature, detection of a wide range of dangerous objects and materials without stopping the flow of people, is realized with high-definition image generation technology that utilizes a radar wave at the millimeter scale.

Radar detection technology built around microwave-based devices are already in wide use, but they require stop-and-go inspections that take several seconds. Metal detection works to shorten inspection times, but cannot find non-metallic substances, which can include explosives and gasoline.

Aware of this, Mori chose to focus on millimeter wave radar, a technology that can inspect for a wide range of dangerous objects and materials very quickly. He knew that the properties of the wave include passing through clothing, that it reflects off metals, such as guns and knives, and is absorbed (scattered) by powders such as explosives. He thought that by taking advantage of these properties, it would be possible to detect dangerous objects and reveal them in high-definition images.

Of course, there were plenty of hurdles on the way to practical use, as Mori explains.

“Getting a high-definition image needs more sensors for the area covered by the radar, which is not good for shortening the inspection time. It also needs more antennas, which pushes costs up. However, using a millimeter wave radar really does improve detection and produces a clean image almost instantly, so that’s why we wanted to use it/millimeter-wave radar, no matter what.

However, another reason for sticking with millimeter-wave radar was its low cost. Millimeter wave radar technology is widely used to prevent vehicle collisions, with the result that the sensors used in signal transmission and reception have grown in sophistication while falling in price. In order for its system to be widely adopted in all kinds of public spaces, Toshiba wanted and needed to take cost into consideration.

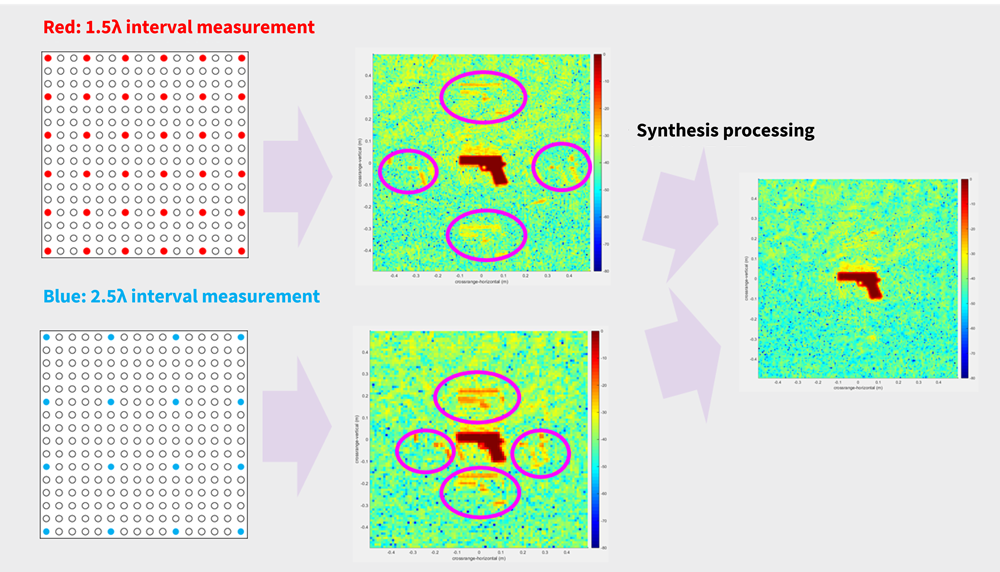

In 2018, Mori and his team of young researchers started to share ideas on how to secure highly accurate detection in a short time, and initiated a trial-and-error search for the best method. They soon realized that if they wanted to get an instant image, the number of sensors needed to be cut significantly. Normally, sensors in an array are installed at half-wavelength intervals, which is several millimeters apart for millimeter waves; but with that configuration imaging takes a lot of time. Mori and his team found that they could generate images without false artifacts by combining images measured with two different spacing patterns—even when sensor spacing was increased. And that wasn’t all …

“We are also involved in processing signal received from satellites,” explains Mori. “We do that with software, which is sort of like the lens on a camera.That experience inspired us to apply the lens of software processing to millimeter-wave radar, and it really improved image accuracy.”

Combining the technologies realized a system that generates high-definition images in less than a second.

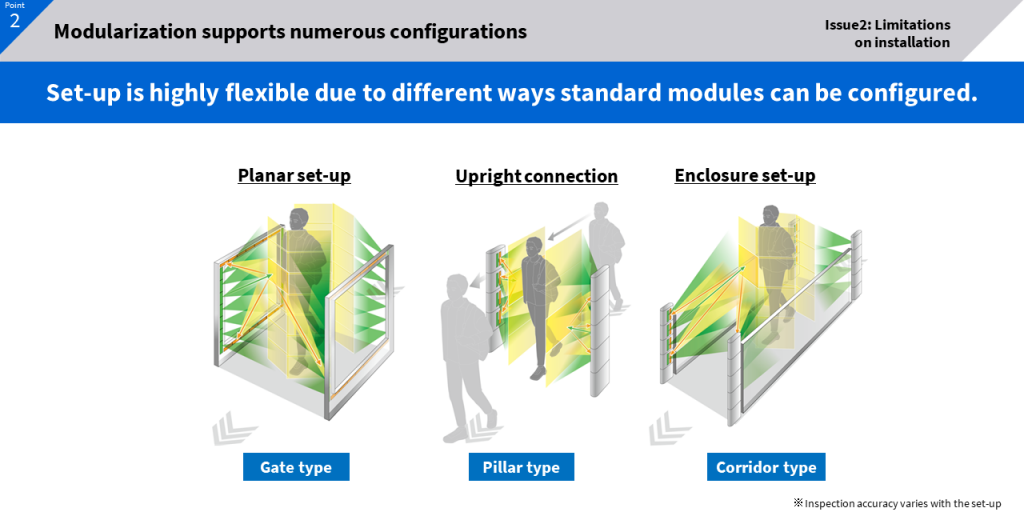

The modularization of sensors that supports configurations for specific environments and site needs was secured by using increasingly cheap millimeter-wave radar ICs, and connecting multiple units into modules. The result was enhanced performance and increased flexibility in configuring systems for sites. Mori’s teams found that simply changing the number of modules and the way they were put together gave them much greater flexibility in realizing the type of installation and the level of detection accuracy required by customers, from gate-type to corridor-type systems.

The target: easy for anyone. A strategy that began with a “5-minute phone call.”

Measures to deliver ease of set-up and operation include using AI for automatic adjustment that makes sure the inspection system delivers appropriate values. This allows it to be installed by anyone, anywhere, without no need for any specialized knowledge—the project team knew that, even if the equipment had excellent detection technology, if it proved difficult to operate or required specialized knowledge, it would not find wide use. The R&D and technology strategy departments worked closely together to iron out operational issues like these.

Emi Kakisada wears a ready smile as she recalls her part in the project. Appointed to develop strategy for scaling up the business, she knew at a glance that the millimeter-wave technology was quite an achievement. But she also realized there would be operational hurdles to overcome, an impression that was solidified by the first demonstration she saw: Mori and his team had to spend a lot of time and effort setting up and adjusting the inspection equipment.

“I thought then that if the millimeter-wave was going to be used in all kinds of public spaces, the need for expertise would be a bottleneck,” she recalls. “I called Mr. Mori and asked, ‘Can you talk for five minutes,’ and in a way, that’s when project really started for me. We ended up discussing the system for nearly an hour, and it was that conversation that led to the idea of modularization and automatic AI adjustment.”

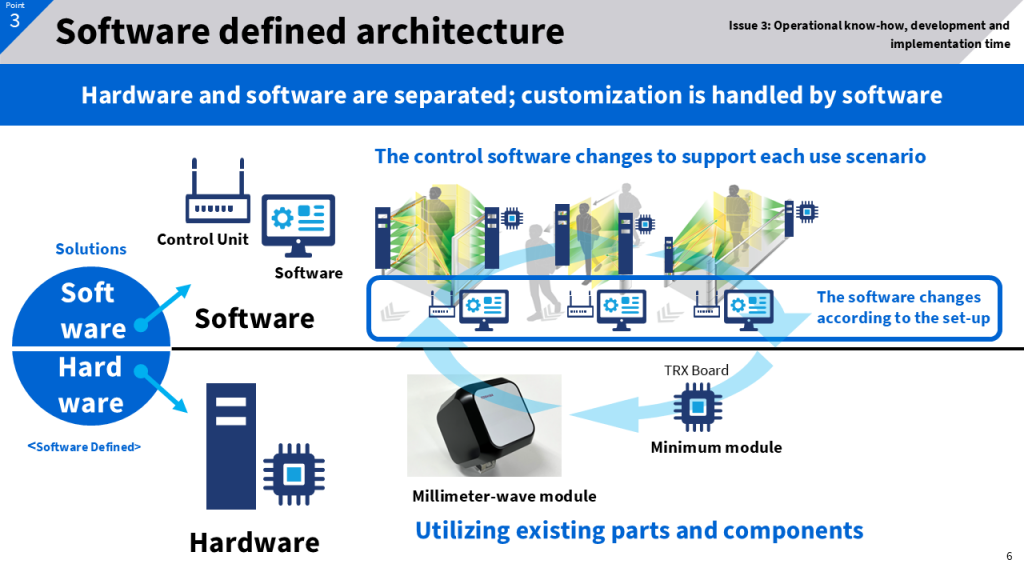

Seeing the demonstration led Kakisada to propose a software defined approach for the inspection system. In the initial phases of digitization, many functions of equipment were executed in the physical hardware layer, but advances in software now allows for the creation of virtual resources that are separate from hardware restraints and that, once developed, can be further refined and updated after initial deployment. This makes systems more flexible, and delivers new value that could not be achieved with hardware alone. Smartphones are a good example of how it works. Users can update the OS and functionality and install the latest applications without having to replace the hardware.

“Of course, we knew that installing the modules would be a challenge,” says Kakisada. “But we also knew that Toshiba has built up a lot of knowledge in AI. I told Mr. Mori that we could solve the problem if we could upload on-site data from the different types of installations, such as a gate or a corridor, and then use AI to automatically calculate the design values.”

“My first response on hearing this was to think that it would be difficult to realize,” recalls Mori. “But what really surprised me was when Ms. Kakisada said, ‘It’s the difficulty of the adjustment that makes it worthwhile.’ Indeed, if you can find a mechanism that makes it easy to do something that everyone thinks is difficult, you have a driving force for the spread of inspection systems that will lead to their practical use and commercialization. The fact that we were able to talk about the issues at an early stage meant we were able to work together smoothly after that.

In her previous assignment, Kakisada worked on scaling up the smartphone business. She knows hardware, but is also well versed in utilizing software to maximize its power and widespread use in society.

“The diversity of human resources is one of Toshiba’s great strengths,” she says. “We have researchers, like Mr. Mori, who excel in hardware technology, and employees like me, and that is why we can come up with innovative ideas. I think that it is important when you work with colleagues with different specialties to really respect other people. I think that we build on that premise, and that by making small compromises we were able to create a game-changing system that deeply integrates hardware and software. I am convinced that winning the Minister of Internal Affairs and Communications Award at CEATEC grew out of that. Our booth at CEATEC attracted a lot of visitors, and I’m looking forward to finding out if there are more ways of using the system than we could ever imagine.”

Right, on to the activity for a secure space management platform business

The launch of the millimeter-wave radar walk-through inspection system is planned for 2026.Toshiba is now meticulously integrating the technologies covered in this article into the system, and fine-tuning performance in readiness for step-by-step release. Testing of the initial version of the system is now underway. Looking beyond that, the next steps will be on-site demonstration testing of the beta-version in 2025, in collaboration with business partners, and then the step-by-step introduction of features.

The most important thing for getting to practical application is building up verification data,” says Mori. “What we do first is carry out demonstrations in different kinds of environments. We know that dangerous objects constantly evolve, and there have been cases where amateurs have made their own weapons, so we are proactive about incorporating innovations that improve detection accuracy, including the use of AI.

Beyond that, we want to continue discussions with client companies that will operate the system, such as railway and security companies. Every company has its own operational environment and needs to detect different objects, so we want dialogues that help us to understand what they want and need, so that we can provide the most appropriate software and functions.”

The project team now envisions a platform business that realizes safe, secure spaces through open development, open operation environments, and joint creation with other companies. What they see is a service-oriented business model that does not end with the sale of inspection equipment, but that continually provides spatial security solutions through the platform.

Kakisada explains this in more detail. “Applying software defined allows us to constantly use the platform to improve security functions, and to customize it to meet the different requirements of our customers. Some customers may want to make temporary use of the inspection equipment, for an event, say, so Toshiba could partner with a leasing company to provide the hardware. We would also like to set up a partnership program and involve other companies, including developers of security-related applications and on-site security companies.”

To close, we asked Mori and Kakisada how they see future prospects for the project.

“My goal is to have many people evaluate Toshiba’s security system and say, ‘Toshiba’s system is the best,’” says Mori. “This is not only because of the high detection accuracy. The ideal security system is one that lets people go about their normal lives without any sense of unease, protecting their safety and security without them even being aware of it. That’s the ideal, and I would like Toshiba to realize it.”

“I am in the position of promoting software-defined security systems at Toshiba. I would like to make the millimeter wave radar walk-through inspection system a success story. Moving forward, we will create even more attractive solutions and help our colleagues at Toshiba to enrich everyone’s lives.” says Ms. Kakisada.