Harnessing the Full Power of the Sun, Part 2 -Toshiba’s breakthrough toward realizing Electric Vehicles (EVs) that run without plug-in charging

2022/09/21 Toshiba Clip Team

- Technological efforts to keep improving the power conversion efficiency of a new type of solar cell

- What are the advantages of a strategy made possible by technological differentiation?

- Goals and aspirations aimed at carbon neutrality, including EVs that run without plug-in charging

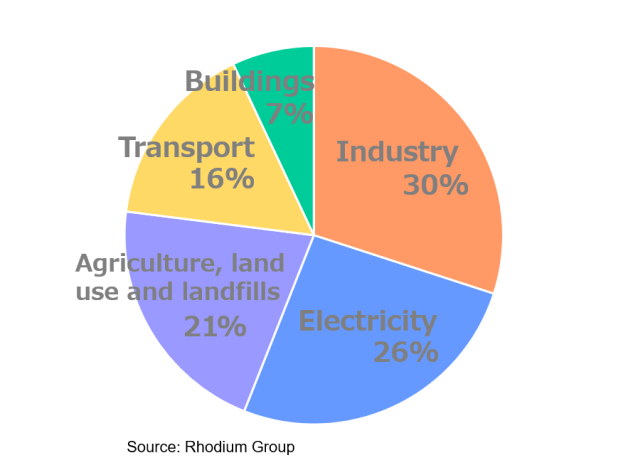

As emphasized in Part 1, greenhouse gas emissions must be reduced to zero in order to curb the adverse effects of climate change. About a quarter of greenhouse gas emissions come from generating electricity. For this reason, there is an ever growing need to generate power from renewable energy sources, which do not emit greenhouse gases directly.

Share of global greenhouse gas emissions by sector

Of the major forms of renewable energy, solar power has seen significant growth in its rate of adoption. Figuring out how to generate power efficiently during daylight hours, when solar light can be used, is key to the technology’s future. To address this issue, Toshiba has developed a tandem solar cell, which is a combination of two types of solar cells that maximize the utilization all of the available sunlight. In Part 2, Yamamoto, who leads the project at the Corporate Research & Development Center, and Shibasaki, who has been toiling daily on the frontline, discuss the mass production of these tandem solar cells, their efforts to reduce costs and achieve high power conversion efficiency, and strategies and outlook for their adoption by society.

Cu₂O makes both tandem and standalone strategies possible

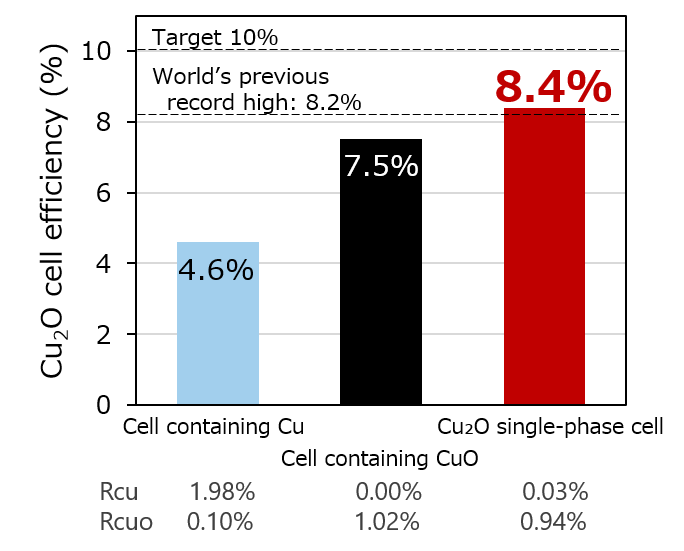

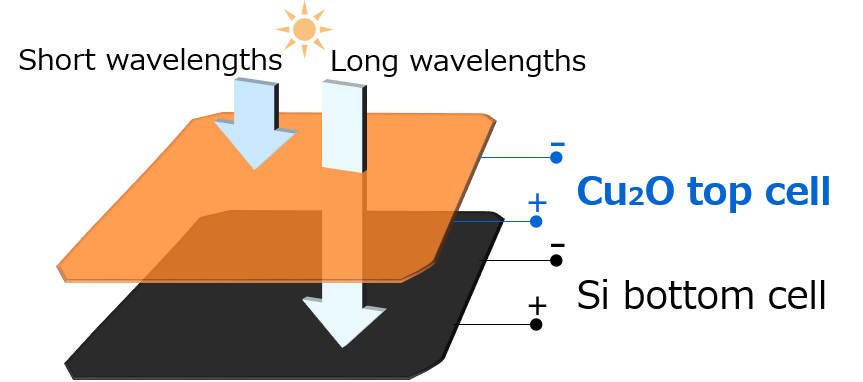

Toshiba’s tandem solar cell combines a cell made of Cu₂O (cuprous oxide), a material that has never before been used in solar cells, with a cell made of conventional silicon (Si). Yamamoto, who achieved the world’s highest power conversion efficiency of 8.4% using Cu₂O, had the following to say. It gets technical, but just remember that solar cells are produced by layering two materials, which form the p-layer and the n-layer.

“Among engineers, most attention tends to fall on the new material, Cu₂O (the p-layer), but it was just as important for us to seek out and improve the material of the n-layer. No, not was important, is important. Even today, we are still researching the n-layer material as we improve the p-layer in order to achieve our short-term goal of 10% power conversion efficiency. This is because the compatibility of the p-layer and n-layer determines the power conversion efficiency.”

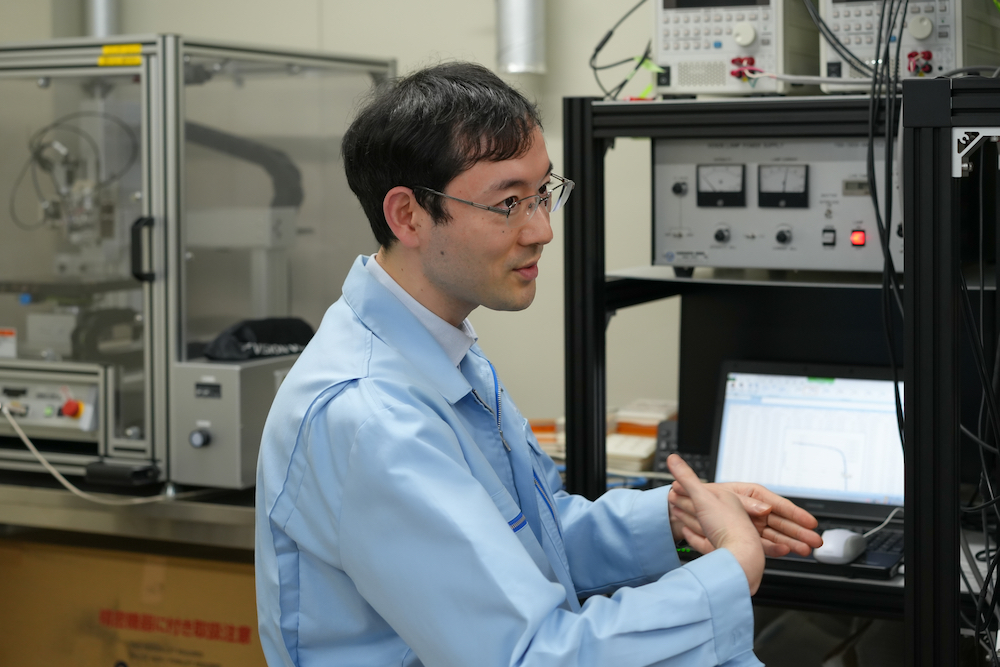

Kazushige Yamamoto, Fellow at Transducer Technology Lab, Nano Materials and Frontier Research Laboratories, Corporate Research & Development Center, Toshiba Corporation

In fact, even after the team successfully developed a thin Cu₂O film for use as a solar cell, there was a period of time when the tandem solar cell’s power conversion efficiency failed to improve. After performing various simulations and studies, the team determined that the cause was an energetic mismatch at the junction between the p-layer (Cu₂O) and n-layer. Therefore, Shibasaki, who is in charge of performing simulations, is still searching for the best match for the p-layer and n-layer by repeatedly adjusting a vast number of parameters and taking measurements.

“The relationship between the p-layer and n-layer is like a seesaw. The power conversion efficiency will go up if we improve the n-layer, but then it will begin to stagnate at a certain level. To increase the power conversion efficiency further, we then have to do something to improve the quality of the p-layer, and when that begins to stagnate, we must readjust the n-layer. We repeat that process over and over.

Initially, we were fumbling in the dark, but little by little, the power conversion efficiency increased. Now we are able to understand the relationship between the p-layer and the n-layer, such as what changes when we manipulate certain parameters, and the correlation between the simulations and actual measured values. We are getting closer and closer to the optimal p-layer and n-layer structure.”

Soichiro Shibasaki, Specialist at Transducer Technology Lab, Nano Materials and Frontier Research Laboratories, Corporate Research & Development Center, Toshiba Corporation

Yamamoto’s team is also developing a process to remove impurities contained in Cu₂O. Until now, the presence of Cu and CuO in the material, although in very small amounts, had reduced its power conversion efficiency. The team was successful in removing these impurities through a proprietary process. The result, as mentioned above, was the world’s highest power conversion efficiency of 8.4%. Yamamoto explains their future outlook and strategy of Cu₂O:

“Our power conversion efficiency target was 10%, but now that we know that the theoretical maximum is almost twice as high, at 19%, we are conducting research and development with an eye toward achieving even higher power conversion efficiency than 10%. Depending on the application, Cu₂O could be commercialized as a solar cell by itself, as well as in tandem with another material, if its efficiency exceeds 15%.

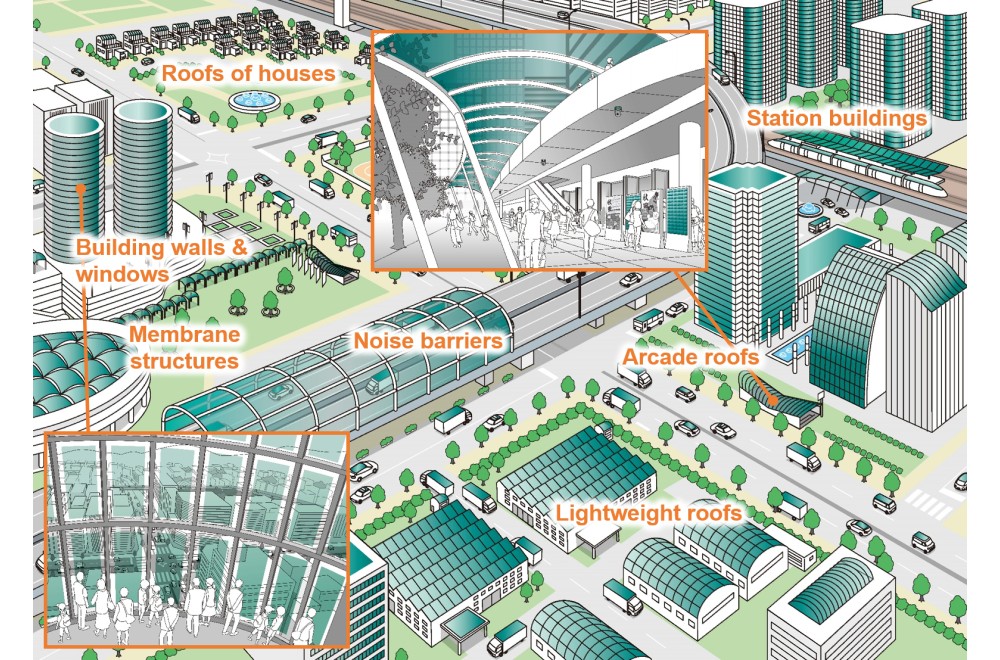

Cu₂O is an extremely hard, durable material, lending itself to use as solar cells in harsh regions such as on islands, where sunlight is strong and damage from salt is a concern, or in cold areas, where frost is an issue. Depending on how research and development goes, we are considering two different strategies: launching it on the market as a tandem solar cell with Si, and starting small with a standalone Cu₂O solar cell before expanding into tandem solar cells.”

By removing impurities such as CuO and Cu, the team was able to achieve the world’s highest power conversion efficiency with Cu₂O

Breaking through barriers to mass production and establishing technological differentiation

While improving the Cu₂O cell’s power conversion efficiency, Toshiba is also developing technologies to mass produce it. A key point is to increase the size of the Cu₂O cell. Shibasaki, who has been working at this task day after day, revealed a hint of enterprising spirit while sharing his outlook:

“The standard size of a Si solar cell, which we will combine with the Cu₂O cell, is 15 x 15 cm. Needless to say, the Cu₂O cell must be enlarged to the same size. Currently, we have succeeded in uniformly increasing the size of the cell to 4 x 4 cm using new equipment we introduced through joint development with Toshiba Energy Systems & Solutions Corporation. By FY2025, we will enlarge it to the same size as a Si solar cell.

The technology that makes Cu₂O transparent is quite unique and is proprietary to Toshiba. Once we enlarge the Cu₂O film to a commercially viable size, this will be a major point of differentiation and will serve as a barrier to entry for other companies. Going forward, we will develop manufacturing equipment for mass production requiring the precise configuration of a large number of parameters.”

At Toshiba, there is a group specializing in manufacturing processes, called the Corporate Manufacturing Engineering Center, with whom the team is closely collaborating. There were many examples of outstanding technologies in the world that have been developed but could not overcome the hurdle of mass production. However, as Shibasaki points out, the hurdle of mass production functions as a barrier to entry for competitors. Overcoming this hurdle will be a major strategic advantage for Toshiba.

High total power conversion efficiency per day, and the ability to effectively utilize solar energy

Toshiba’s tandem solar cell has more features that differentiate it from others. On this point, Yamamoto cuts right to the chase, saying, “Actually, the structure of ours is different than that of other tandem solar cells. Toshiba’s tandem solar cell has electrodes with four terminals.” Let’s look carefully at what he means.

The majority of tandem solar cells in existence are monolithic units in which the two types of cells are manufactured in a contiguous process, and the electrodes of each are connected in series to two terminals. Toshiba’s tandem solar cell, on the other hand, is made of Cu₂O and Si in separate processes, then stacked using an adhesive. As each cell has its own electrodes, this naturally results in a four-terminal structure. Yamamoto elaborates on the implications of this structure as follows:

“Solar cells, especially those made of Si, generate peak power when sunlight hits their absorbing surface perpendicularly. However, the power conversion efficiency tends to decrease when the sun’s rays hit the surface at a tilted angle, and in a tandem solar cell, a gap in power generation between the two types of cells can be expected. When this happens, if the electrodes of each cell are connected in series to two terminals, a phenomenon occurs where the power is drawn to the cell generating the least power, resulting in electrical loss.

Some may say that the four-terminal type we are working on requires more labor to manufacture, but on the other hand, there is no electrical loss as with the two-terminal type, since power generated by each cell is supplied separately. Considering how much the sun’s rays shift over the course of a day, our four-terminal type has a greater advantage in terms of total power conversion efficiency per day. I think the reason why many tandem solar cells use two terminals is that people, even those who are familiar with solar cells, have a fixed idea that tandem cells are fabricated by connecting each cell in series. We chose a process and terminal structure based on rational decisions, not on common sense.”

Diagram of the Cu₂O/Si tandem solar cell’s four-terminal structure

Making EVs that run without plug-in charging attainable in the near future

Currently, Si-only solar cells may be low-cost, but their power conversion efficiency is limited to about 27%, and it is theoretically difficult to achieve a higher efficiency than that. Tandem solar cells developed for space exploration use a semiconductor called gallium arsenide (GaAs), which has achieved a power conversion efficiency of about 32–33%, or 1.5 to 2 times higher than Si. These, however, cost hundreds to thousands of times more than Si cells. Yamamoto stressed the importance of achieving social implementation, adding, “If we take the extravagant route, it may be possible for us to replicate our target power conversion efficiency of 30% for tandem solar cells using gallium arsenide, but this would lead to a significant increase in costs, which would not be acceptable for widespread use in society.” In this context, what strategy does the team envision for Cu₂O/Si tandem solar cells?

“Si, which is currently the predominant material for solar cells, has been developed over many years to bring down its cost, but its power conversion efficiency is still capped at 27%. On the other hand, gallium arsenide, which has a high efficiency of over 30%, is extremely expensive. For example, it can currently cost as much as 100 thousand dollars just for a GaAs solar cell to generate 1 kW of electricity. Since our Cu₂O/Si tandem solar cell can provide both low cost and high efficiency, we wanted to come up with a product that requires a large amount of power, which Si alone cannot provide on a small footprint.

Our quest to find needs for a solar cell that offers high power conversion efficiency in as little space as possible led us to focus on the mobility sector, which includes electronic vehicles (EVs), trains, and drones, as one of our targets.”

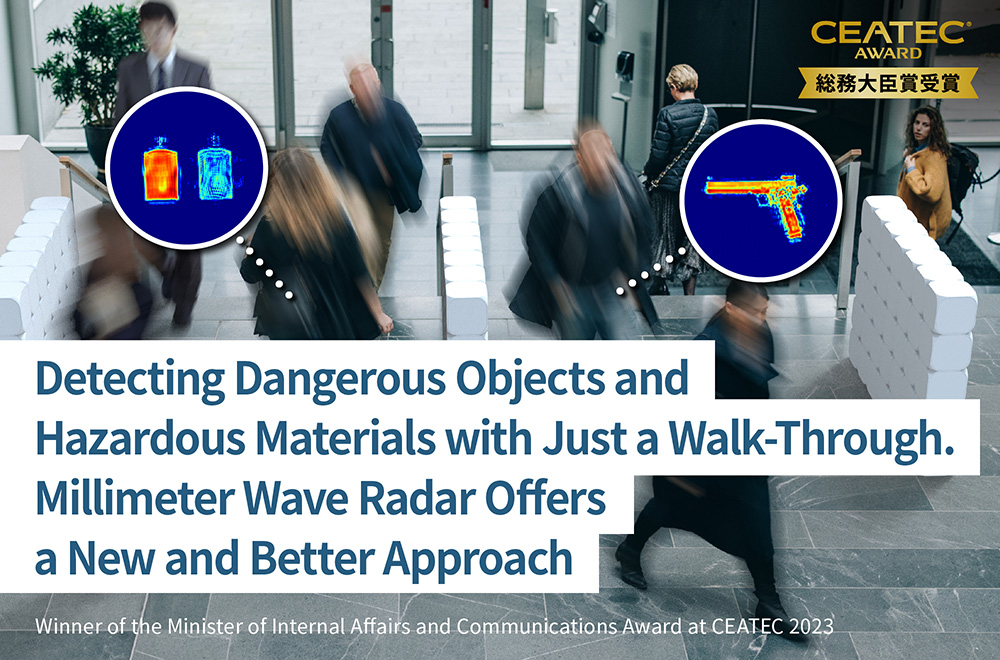

One such goal set by Toshiba is “an EV that runs without plug-in charging.” For example, if Toshiba’s Cu₂O solar cells, which have a power conversion efficiency of 8.4%, are combined with Si solar cells, an estimated power conversion efficiency of 27.4% can be achieved. Assuming that the solar cells cover an area of 3.33 m2 on the roof of the EV and that the standard power consumption of the EV is 12.5 km/kWh, the amount of power generated per day will enable the EV to travel approximately 35 km. This is enough distance to free users from the stress of having to stop in order to recharge the EV battery. Plus, it would also contribute to carbon neutrality, making it a true innovation.

Conceptual image of Cu₂O/Si tandem solar cells installed on an EV

To conclude this story, we once again asked Yamamoto, the team leader, about his vision and thoughts on the technological development and its applications in society.

“As the power conversion efficiency of solar cells improves and costs come down, applications for the technology will expand. We estimate the potential power conversion efficiency of Toshiba’s Cu₂O/Si tandem solar cell to be about 40%. In order to get as close as possible to achieving that potential, we are currently in the midst of drafting a new roadmap that involves revising our power conversion efficiency target for Cu₂O solar cells upwards from 10% to something higher.

Measures to combat global warming and climate change continue to be urgent issues. I have a daughter, and I intend to do what I can to contribute to the development of renewable energy technologies, so that society can be a safe place for her to live when she grows up. And, in the future, I hope I’ll be able to point out the no-plug charging EVs that have become commonplace in the city and brag to her, ‘Those are powered by technology your dad made,’” Yamamoto says, laughing.

![]()