As data becomes one of key ingredients to shape global economies, digitalization is gaining momentum in the industrial world. The adoption of technologies including robotics and artificial intelligence is moving companies up the manufacturing value chain, shifting human capital to other platforms for more efficient outputs.

Toshiba has a long history in robot development. In the 1820s, Hisashige Tanaka—one of Toshiba’s founders, nicknamed “Karakuri Giemon” (“karakuri” means “mechanical doll” in Japanese)—created archery dolls known as “Yumihikidoji” which could notch an arrow into a bow and shoot it with the same sophisticated movements as a human being. That manufacturing DNA has been passed down to the Toshiba of the 21st century.

“Yumihikidoji,” mechanical archery dolls with the same sophisticated movements as human beings

This video was released on November 5th, 2018.

Developing modern robots to address social issues

“Toshiba currently has research facilities spearheading its robotics development. The Toshiba Corporate R&D Center and the Toshiba Corporate Manufacturing Engineering Center play a central role in developing robots.

The Corporate R&D Center researches and develops cutting-edge robot technology and in the past, it invented the Otomo Robot which uses image and voice recognition technologies to identify human beings. It also exhibited the “Voice Discerning Robot,” which can distinguish voices of different people, at the Aichi World Fair in 2005. In recent years, it has been researching the AI essential to making robots and whole systems intelligent.

The Corporate Manufacturing Engineering Center focuses on researching and developing equipment to enhance Toshiba’s productivity. Examples include the development of manufacturing equipment such as automated assembly equipment for HDDs, and liquid injection and sealing machine for Toshiba’s SCiB™ rechargeable batteries at our manufacturing sites.

We have established a task force to unite the research labs with the business divisions and utilize industrial robot technology to work towards solving social issues such as labor shortages. Our business divisions also develop and sell appliances like letter sorting machine and automatic ticket gates.”

These are the words of Takashi Miyauchi, Deputy Director of the Toshiba Corporate Manufacturing Engineering Center, Toshiba Corporation (title at the time of the interview).

Takashi Miyauchi, Deputy Director of the Toshiba Corporate Manufacturing Engineering Center, Toshiba Corporation (title at the time of the interview)

While the two research centers contribute to the sustainability of the business in providing catalyst for innovation and growth, Toshiba recognizes the importance of bridging innovation with practical applications. In Toshiba, R&D is closely aligned with the business strategy to generate new customer values.

Satoshi Ishikawa of the Technology & Production Services Department (department at the time of the interview) further explains, “An example would be Toshiba’s letter sorting machines. By applying our strengths in the field of mechatronics and image processing & object recognition, the Toshiba Group is working together as one to meet client’s needs. Our technologies are able to optimize distribution, help with labor shortages and maintain and inspect infrastructure.”

Satoshi Ishikawa, Technology & Production Services Department, Toshiba Corporation (department at the time of the interview)

Toshiba has been developing robots since its founding, so there is plenty of variety in development, just as with its businesses and products.

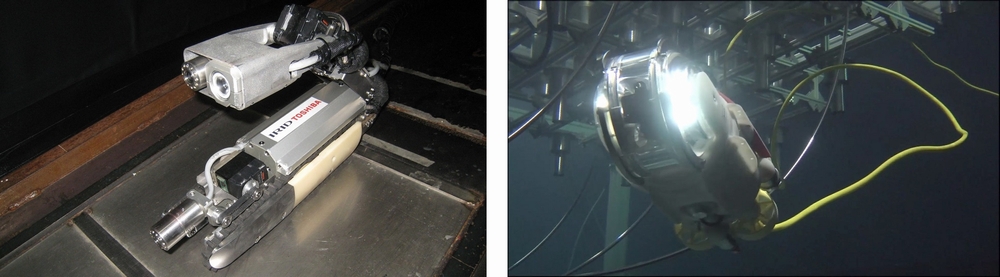

“Our robots fall into two main categories: robots which can replace labor intensive work and robots that perform tasks beyond human physical ability. The robots working at the Fukushima Daiichi Nuclear Power Station are an example of robots doing work which humans can’t. They carry out a detailed survey of areas in the nuclear plant that are inaccessible to us. In other areas, there is also an increasing demand for robots to mitigate labor shortages.” (Miyauchi)

Self-propelled robots and underwater ROVs exploring the containment vessel at the Fukushima Daiichi Nuclear Power Station

(Courtesy of IRID: International Research Institute for Nuclear Decommissioning)

The evolution of robots capable of reducing labor intensive work

Robots were originally used to carry out repetitive mechanical tasks. Robots are now performing tasks closer to what humans do, and so they are required to have more varied motions as well as autonomous robots that can see, think and move.

One example would be the Automated Guided Vehicles (AGV)(*1) which are seeing increased practical use in manufacturing and distribution.

*1: Automated Guided Vehicle

A self-driving transport vehicle that functions without human operation.

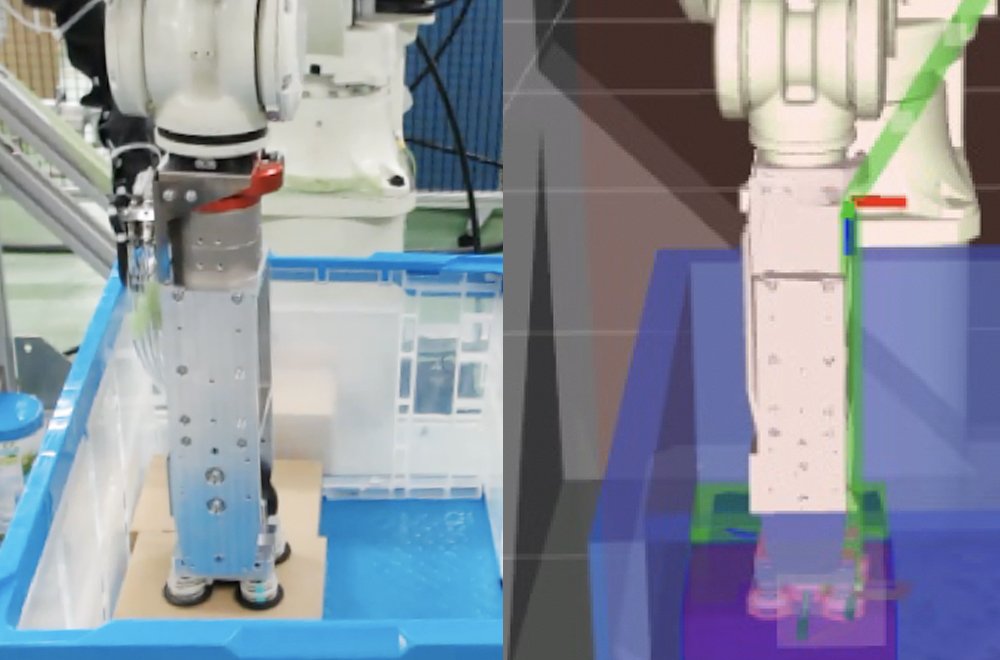

“The AGVs working in Toshiba’s factories aren’t just capable of transportation. They can also use a robot arm to load and unload goods automatically. We are also working on developing both conventional AGVs that move by recognizing and following lines laid out on the floor, and next-generation AGVs equipped with an AI program to instantaneously analyze information from lasers and image sensors to avoid obstacles and respond to situations around them. With these developments, we’ll be able to use AGVs not only in manufacturing factories but at distribution sites as well.” (Miyauchi)

AGVs transport goods safely in factories and distribution sites by using SLAM technology(*2) to recognize terrain and obstacles automatically. If this can be implemented on a more sophisticated level, it will undoubtedly contribute greatly to alleviate labor shortages.

*2: Simultaneous Localization and Mapping

A technology which identifies an object’s location and maps its surrounding environment at the same time.

A next-generation AGV that is expected to make waves at distribution sites

(Part of this research and development was outsourced from the New Energy and Industrial Technology Development Organization (NEDO))

This video was released on November 5th, 2018.

Another area is non-destructive inspection (*3) that checks the strength of welded objects.

*3: Non-destructive inspection

A method for inspecting the interior of machine parts and components without destroying them.

“The Matrixeye™ ST, current product of Toshiba, is a handheld device that inspects the object by scanning the spot-welded parts using ultrasound. A human operator has to make minor adjustments to the way the ultrasound probe is applied as they perform the inspection. We are also exploring if the inspection of large welded objects such as vehicles could be done entirely by a robot. We are currently developing algorithms for automation through AI and then applying those algorithms to the robot arms to make automatic inspection possible in the future.” (Miyauchi)

The latest non-destructive inspection robot featuring a fusion of AI and a robot arm

This video was released on November 5th, 2018.

Robots are now being used in tandem with people to maximize production efficiency. In this situation that we are making steady progress with robot automation, we still have some challenges to tackle.

“Cutting costs and speeding up work are two big themes we are working on, and we have the other big issue. It is safety. Since robots will be working in the same space not only with other standard robots that carry out programmed actions but also with human beings who can make unpredictable moves, we need to put meticulous safety measures in place.” (Ishikawa)

Ishikawa talks about the future, “If we can resolve such issues, we can devote our time to other creative tasks.” Robots are shifting away from being objects used to replace humans. Right now, they are being used in tandem with people to maximize production efficiency in a limited environment.

There is a possibility that we can fully rely on robots to carrying household chores in the future. The current robot development sheds light that practical applications can be very wide.

![]()