The ABCs of Semiconductor Development – a Lesson from a Toshiba Engineer –

2019/10/23 Toshiba Clip Team

“I’ve loved playing with parts from broken PCs and appliances ever since I was a child. You could say that semiconductors were my toys. I enjoyed finding electronic devices and taking them apart to see what was inside. Of course, I couldn’t tell what semiconductors were used for just by looking, so I did my best to look them up in books, learn more about them, and before I knew it, I was totally obsessed with the subject.”

A semiconductor is a material such as silicon that has electrical conductivity between that of an insulator and that of a conductor. However the term “semiconductor” generally refers to an electronic part or circuit made by taking advantage of that material property. Semiconductors, or chips, are used in almost all of the appliances around us, from PCs to smartphones. The use of automotive LSIs in self-driving cars and driver-assistance has received a lot of attention recently as well.

In this article, we will learn about the basics of chip development from Toru Sano, an engineer with 10 years of experience working in research and development for Toshiba, who has a keen interest in semiconductors since childhood.

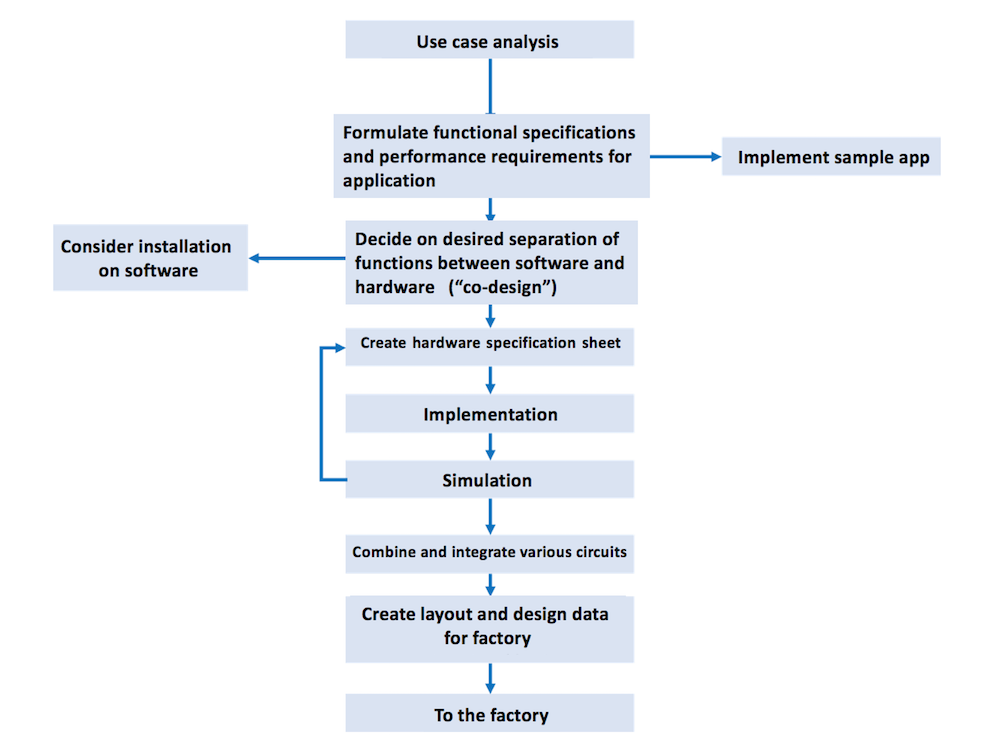

How to develop a semiconductor

Sano says, “The semiconductors of today are much smaller and have much higher performance than those of my childhood. Semiconductor technology is progressing at an incredible speed and so in R&D, we have to predict what kind of functions and algorithms will be needed by the market in three to five years. We start development by determining the characteristics the chip should have and the application it should handle, through market analysis and interactions with customers.”

Toru Sano, Electronic Devices & Storage Research & Development Center, Toshiba Electronic Devices & Storage Corporation

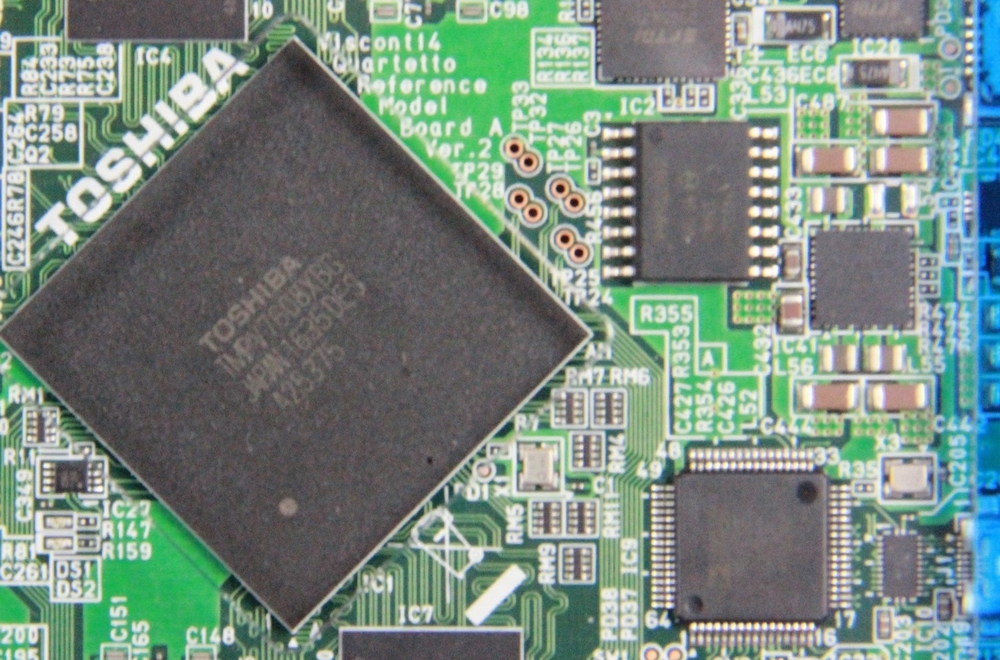

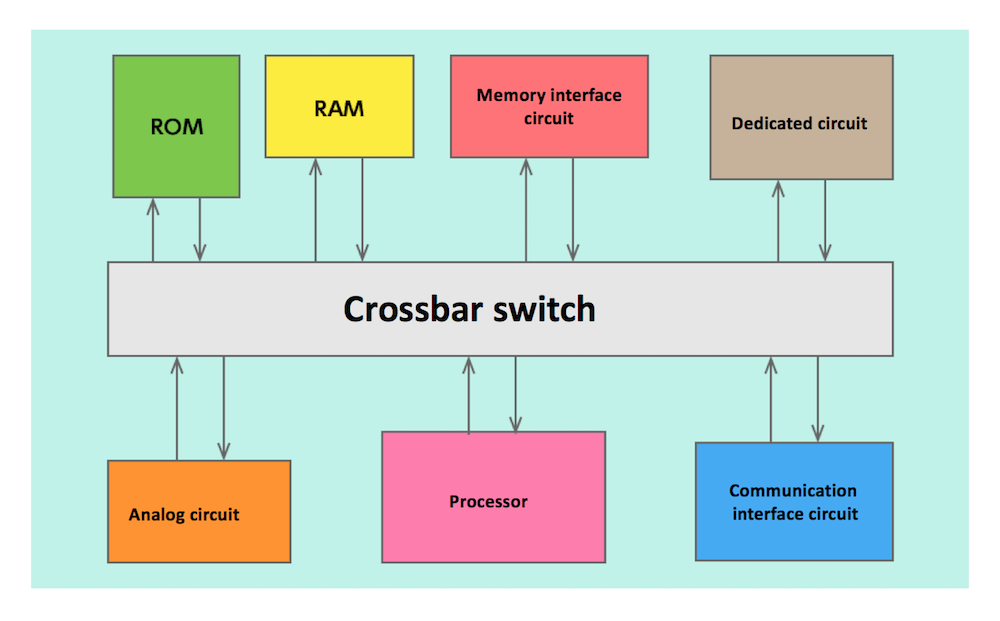

A “system LSI” is a chip where multiple circuits that perform necessary functions are integrated in a single chip. The Visconti™, an image recognition processor that Sano is working on is one such example. System LSI chips are generally made from a combination of software that operates according to a programmed order and hardware that continuously processes data as designed. Sano is responsible for hardware design.

One example of a system LSI hardware

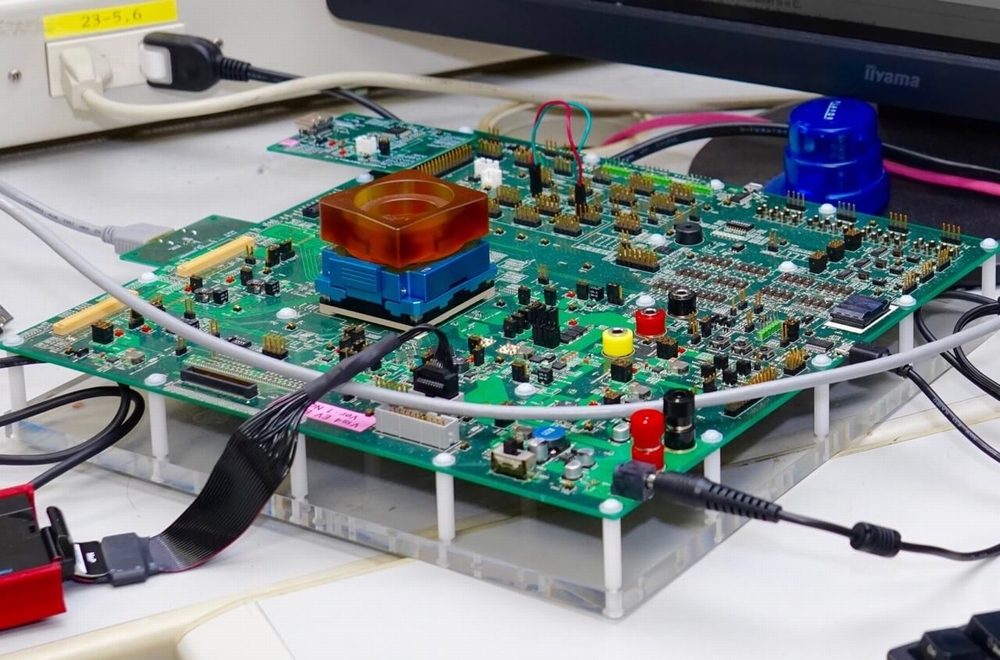

Once the scope of the application is decided, the functions to be executed by software and hardware are assigned. To get an idea of the hardware requirements, a simulation of the desired operating characteristics is run and used to develop a specification document. This covers decisions on circuits that will be used to handle the assigned functions, calculate input data, and other specifications. This is also when overall chip size is decided. Once the specs are settled, they become the basis for implementation.

The workflow of chip development

“However, determining the specs doesn’t assure easy implementation,” Sano explains, “For one thing, semiconductor technology is always changing and we have to keep abreast with the latest trends. Other challenges may occur as well: for example, we might get a request for additional functions just as we have finalized the spec document. Or we might have to redesign the chip to find a balance between the chip’s performance and power consumption.”

However, according to Sano, there are ways to minimize the need for such reworking processes.

A semiconductor is a microcosm of society

“You have more flexibility with software, as you can adjust the code even after the software is programmed. It’s much harder to change hardware once it has been designed, and that’s why one of the secrets of efficient hardware development is to clearly divide the functions of the software and the hardware from the very start, so that the hardware has clearly designated tasks.” Sano continues, “The best way to allocate functions is through evaluation of an application simulation. It’s also important to create a design that can be modified later on. For example, putting items that have little effect on the size of the circuits on the hardware first gives us the option to remove them later if necessary.”

Sano says the happiest moment in chip development is when he sees a machine functioning with the chip he spent so much time and effort in developing.

“A single chip contains circuits I worked on as well as those worked on by other members of the team. There are almost as many parts as there are human beings on Earth, and they function in close connection with each other. I feel a little strange every time I hold a chip in my hand. I feel like this is a small world where parts interact closely with each other just like human beings do, helping to create things that are needed or will soon be needed by people. In that sense, I think we can call semiconductors a microcosm of the real world.”

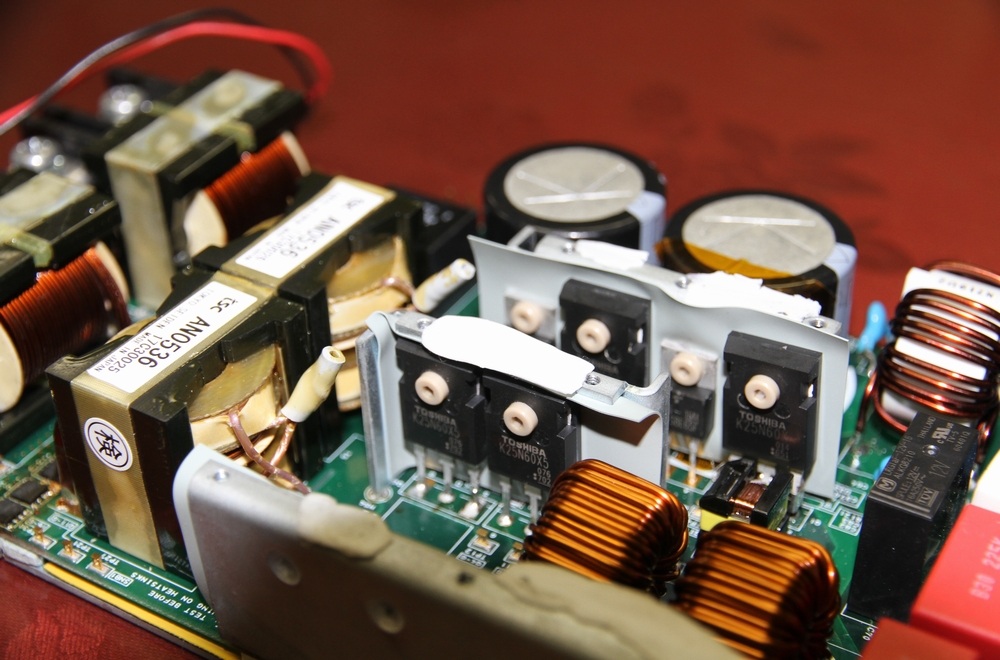

Myriad circuits are formed on single chip

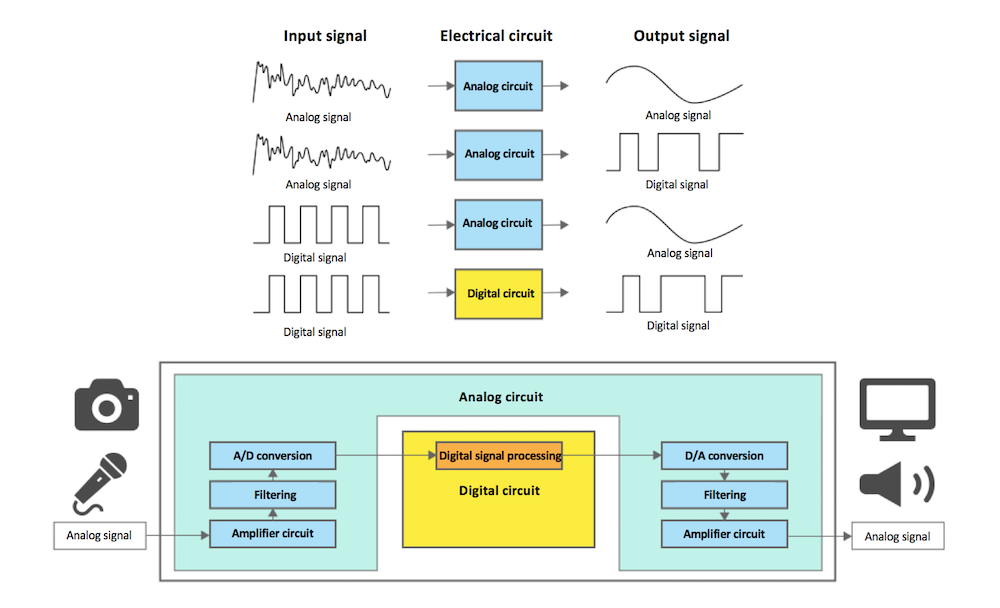

Toshiba’s major advantage in chip development is knowledge accrued from being in the industry since 1958. Many of today’s cutting-edge system LSI are made up of digital circuits that process information as 0s and 1s. But there are also analog circuits, such as transistors that show information as a continuous waveform, and the system LSI that Sano develops largely use analog circuits, both on board and for communication with peripherals. Toshiba’s cumulative know-how in this area really comes in handy.

Circuits that convert digital signals to digital signals are called digital circuits.

Sano says “The history of semiconductors has been a constant battle between size and cost. When we try to develop smaller chips, the costs skyrocket, so does heat generation, which interferes with operation. With such restraints, we can’t put all the functions we want on a chip, so we try to figure out ways to make them smaller and realize higher performance at the same time.”

Advances in semiconductors have been gained through this kind of step-by-step developments. In Sano’s opinion, “If we could restart the history of humanity from the beginning, I don’t know if we would be able to reinvent semiconductors. Who knows, maybe we would come up with a completely different product instead. The reason semiconductors were able to advance this far was because of the accumulation of inventions such as the vacuum tube, and the progress of computers, inspection devices and other machines. It’s not something that happened overnight.”

Semiconductors are the fruit of the humanity’s engineering history.

*Visconti™ is a trademark of Toshiba Electronic Devices & Storage Corporation.

*Other company names, product names, and service names mentioned herein may be trademarks of their respective companies.

![]()