We are Toshiba: How One Man Decided to Look for a Better Way and Improved the Procurement Process

2023/09/15 Toshiba Clip Team

- An organization and workplace where innovation is welcomed.

- An idea becomes a solution for the entire company.

- Embodying the Toshiba value, “Look for a better way.”

Procurement negotiates forests of rules and regulations to make sure that parts and materials, that meet specification and price requirements, are on site and at hand when manufacturers need them. However, the lingering inflationary effects of the pandemic and increasingly uncertain world politics are bringing turmoil to already complex supply chains, to the point where suppliers are suspending business, and determining appropriate prices is more difficult than ever. One person keenly aware of these problems is Seita Shimizu, who works in procurement at Toshiba Infrastructure Systems & Solutions Corporation. He has made his own contribution to finding a way forward.

Leveraging data analysis in procurement, the backbone of manufacturing

Toshiba Infrastructure Systems & Solutions Corporation wide-ranging businesses include communications solutions that support the mobile networks essential to modern life. Among its products are equipment for local 5G networks and repeaters that realize use of mobile phones in areas with weak signals, and Shimizu’s job is to procure their cable harnesses: assemblies of cables that supply power or send signals, with already soldered connectors for connection.

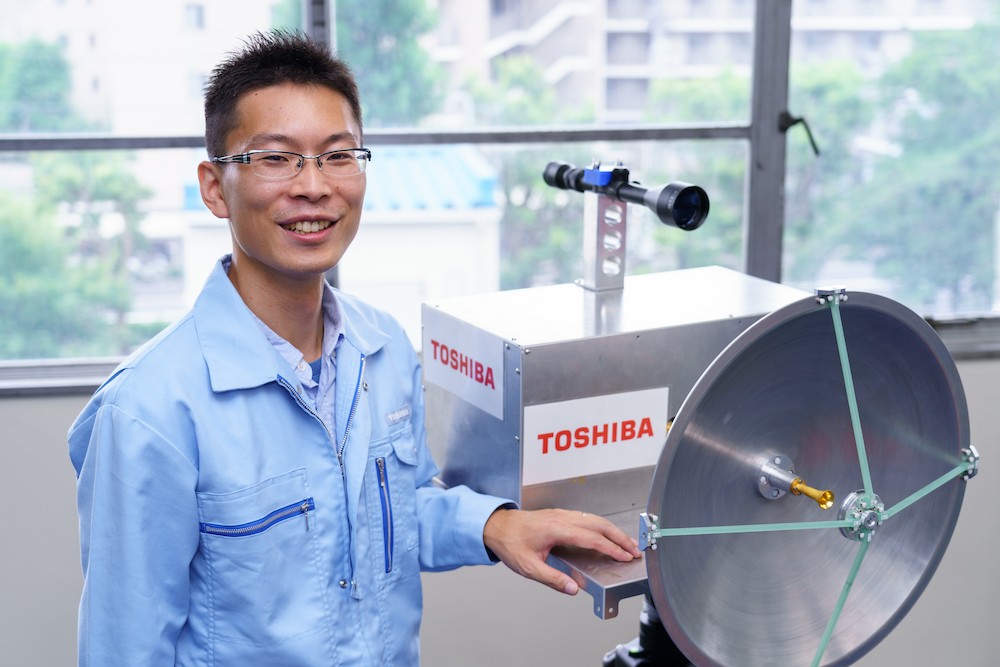

Seita Shimizu, Procurement Group 1, Fuchu Procurement Dept., Procurement Div., Toshiba Infrastructure Systems & Solutions Corporation

“I’ve been a buyer of parts for manufactured products since I joined Toshiba,” explains Shimizu. “We get internal orders, ask our suppliers for quotes, and scrutinize the specs and price. If they look good, we place the order. We also coordinate delivery, as failure to get the parts in time brings production lines to a halt. So buying is all about confirming the product, setting up the delivery day and making the buy. That’s what I threw myself into in my first year of work.

As he entered his second year, Shimizu took another look at the procurement operation and realized just how individualistic the process was, and that price decisions differed from person to person.

“Experience is a big factor in price decisions,” he says. “A buyer like me, with limited experience, can sometimes struggle to make decisions. I started to wonder if we could create a system that used past data to determine appropriate prices, even with orders for new product specifications, with no precedent.”

From that beginning, Shimizu went on to develop a completely novel pricing tool based on AI machine learning. He was able to do this because he had long been fascinated by data analysis, and in university his seminar, his main focus of study, was on statistics. One of the reasons why he joined Toshiba was the desire to work in an area where he could utilize his analytical skills.

“I am from the Tokai region of central Honshu, Japan’s main island. I was born in Gifu prefecture, which is landlocked, but went to university in Aichi prefecture, also in Tokai but on the Pacific coast. Tokai is a manufacturing hub, especially for automobiles, and I always felt drawn to manufacturing. Of course, I knew Toshiba as a company and brand, and grew up watching its ads on TV. All this led me to an internship at Toshiba during my third year at university, and that was a big turning point in my life.

“My internship was in production management, and that is where I met someone working in procurement. Our conversation made a deep impression on me. It left me feeling really drawn to procurement, and I saw it as a bridge between the company and the outside, all grounded in extensive communication. I decided to apply to Toshiba, and hoped to be able to use my skills in data analysis in procurement. The internship, an intensive two-week program, was a real turning point in my life.”

Being aware of issues and having ideas that leverage a specialty field assisted the work process reform

The products Shimizu procures are usually custom made, and it is rare to reorder parts with the same specifications. To meet the specification, orders of such parts are placed by fine-tuning the size of previously procured one. Naturally enough, it’s the kind of work where extensive experience is a big help—and where individualistic decisions are a cause for concern. Say someone spends five or 10 years cultivating expertise. If they are replaced, the new person will have to build up a knowledge base from scratch.

“That is a real waste,” says Shimizu. “The way I saw it, it would be a real asset for the entire company if we could use a common standard for deciding prices. I wanted to develop a pricing system where you could enter variables like cable harness length, type of connector and quantity, and other conditions, and get a price estimate,”

Shimizu did just that, applying his training in data analysis and testing the tool’s practical application. He took know-how and experience gleaned from work processes, and successfully advanced his desire to turn tacit knowledge into explicit knowledge, an asset that enhances the quality of procurement operations. Support for his efforts and the realization of the tool came from Toshiba’s corporate culture, which understands that younger employees can see things with a fresh eye and look for a better way with free-ranging ideas.

On the way, Shimizu had to overcome obstacles, especially in collecting data for machine learning. There was no database of spec sheets, and the sheet themselves differed in format, depending on who made them. Over the course of his second and third years as a buyer, Shimizu patiently entered data, refining the tool’s level of accuracy as he did. He tested it multiple time, and fine tuned the variables to produce the best price analyses. Then he did it all over again, many, many times.

However, Shimizu’s efforts did not go ignored. The Procurement Division welcomes individuals who use their strengths and capabilities to take on challenges, and Shimizu soon received backup from his colleagues and cooperation from other divisions. Currently, he is working with an educational team that is advancing Toshiba’s management strategy of using strengths in data, and many people expect to see Shimizu’s idea broadly implemented.

“Fuchu Complex’s Procurement Department had no history of initiatives based on machine learning,” says Shimizu. “I didn’t have an AI model I could reference as a model for harnesses, but my boss understood the situation and let me work on developing a model alongside my work as a buyer. The turning point came at the Procurement Division’s activity presentation event, where my presentation interested many people. That instantaneously propelled interest in the tool, and now we are a point where we are even looking to collaborate beyond the division.”

Look for a better way—this leads to organizational reform and personal growth

Shimizu’s eyes are set on the future, and he hopes to take the tool beyond price setting to the automation of procurement work. If the AI can carry out routine work, that frees people to focus on work only people can do, such as price negotiations. This also advances the goals of selection and concentration in Toshiba’s select-and-focus strategy for procurement.

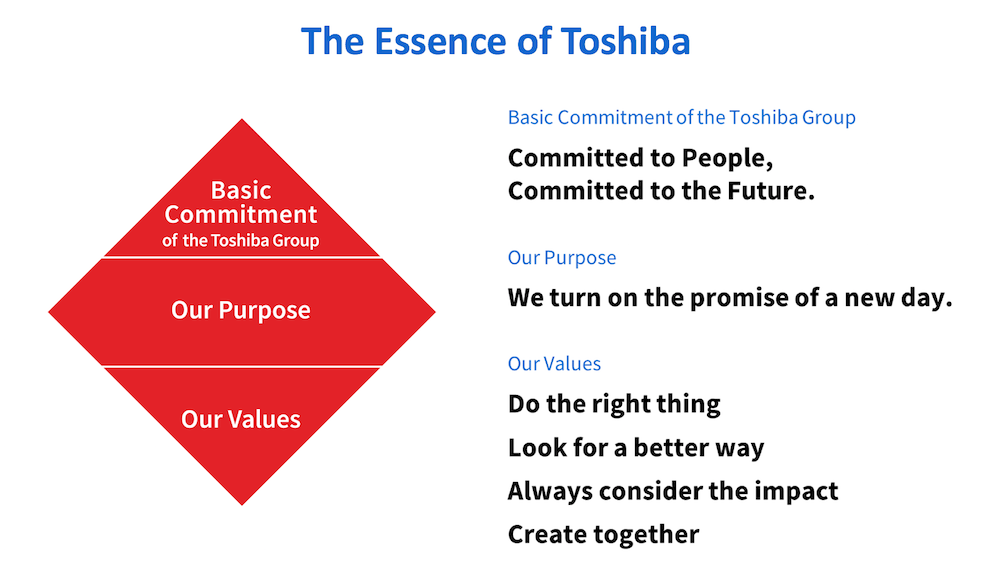

Shimizu joined Toshiba in April 2020, beginning his work in procurement as the tightening grip of COVID-19 realized a tumultuous global situation. His first-hand experience of supply-chain instability and uncertain energy supply, the uncertainties of the times, reinforced his conviction that we should embrace analysis based on objective data, not rely on human instinct alone. Since then, Shimizu has kept one of Toshiba’s values, ‘Look for a better way,’ close to heart. Well aware that we live in a world of constant change, he strongly believes that we need to confront challenges by always asking whether conventional approaches are best—or is there a better way?

“Ground decision in solid reasoning,” he says “That’s my guiding principle in business. I make sure I can explain any decision or statement. I think this approach ties into another Toshiba value, ‘Do the right thing.’

Shimizu says he makes decisions based on solid reasoning when negotiating with suppliers

“The idea for pricing tool came from that value. Calculating prices in advance will simplify exchanges with our suppliers when we receive quotes, and also reduce the need to execute competitive bids, which used to be necessary until now. This will not only optimize our work but also reduce burden on our suppliers.”

During negotiations between individuals, buyers can lean on personal relations and say things like, “Could you give me a lower price this one time?” However, appropriate decisions are the proper approach to relationships between businesses, and they are realized through objective assessments. Enter the pricing tool. With it, buyers can negotiate with suppliers on the basis of solid reasoning. This advance is the result of a desire to be a true professional in procurement. A determination to “Do the right thing” led to “Look for a better way.”

As we have seen, Shimizu’s efforts are now extending to information sharing and technology exchanges with Toshiba Group companies, and with these moves the pricing tool is growing in presence. At this point, in the third year of his career, Shimizu is determined to grow as buyer by gaining more experience and knowledge, while also working to promote operational reforms across the board,

“I could use data analysis skills I studied at university to develop the pricing tool. I worked on it steadily, and it slowly won recognition, and I’m happy it led to lateral ties of information sharing and technology exchanges. Of course, there’s still a lot I have to learn as a buyer. Keeping that in mind, I want to continue drawing on my strengths so that people will say, ‘Seita Shimizu is the person we can rely on to improve and automate procurement operations.’”

Shimizu’s credo is “Always be true to what is central to my life.” In high school that was baseball, and in university, he threw himself into studying data analysis. In Toshiba, he has devoted himself to his work as a buyer, while also working to improve the procurement process. Shimizu brings a sincere approach to everything he does. The project to improve the procurement process grew from a desire to find a better way of doing things, but sincerity is always at the core of what he does. As someone who chose his career path on the basis of his internship experience, Shimizu extends the following message to those considering joining Toshiba in the future.

“Work makes up a large part of life, and in leading a fulfilling life it’s important to be able to express yourself at work. I think people who are choosing a career path and will soon start their working life, including anybody considering Toshiba, keep in mind the need to have fun when doing your job. Choose a job that you can enjoy.”

A ready smile and sincere personality draw people to Shimizu

![]()

Related Links

*This section contains links to websites operated by companies and organizations other than Toshiba Corporation.

Procurement Toshiba