From problem to resource: Flying planes with fuel derived from CO₂

2024/09/12 Toshiba Clip Team

- As the world continues to devise measures to combat global warming, all eyes are on P2C—a technology that converts CO₂ into a resource.

- Commercial flights with a jet fuel derived from CO₂: six companies are working together to achieve this goal.

- The capabilities of individuals become the power of the team.

UN Secretary-General Antonio Guterres did not hold back in his July 2023 warning of extreme weather events and the need for action: “The era of global warming has ended; the era of global boiling has arrived.” This growing sense of urgency about rising temperatures and changing climatic patterns is driving demands to first cut CO₂ emissions, our immediate enemy, and then bring them to zero, to realize carbon neutrality. People around the world are working day and night to do just that. But less well known is a remarkable project, already underway, that aims to go a step further: to end the impact of CO₂ and turn it into a resource: the Power to Chemical Project; P2C.”

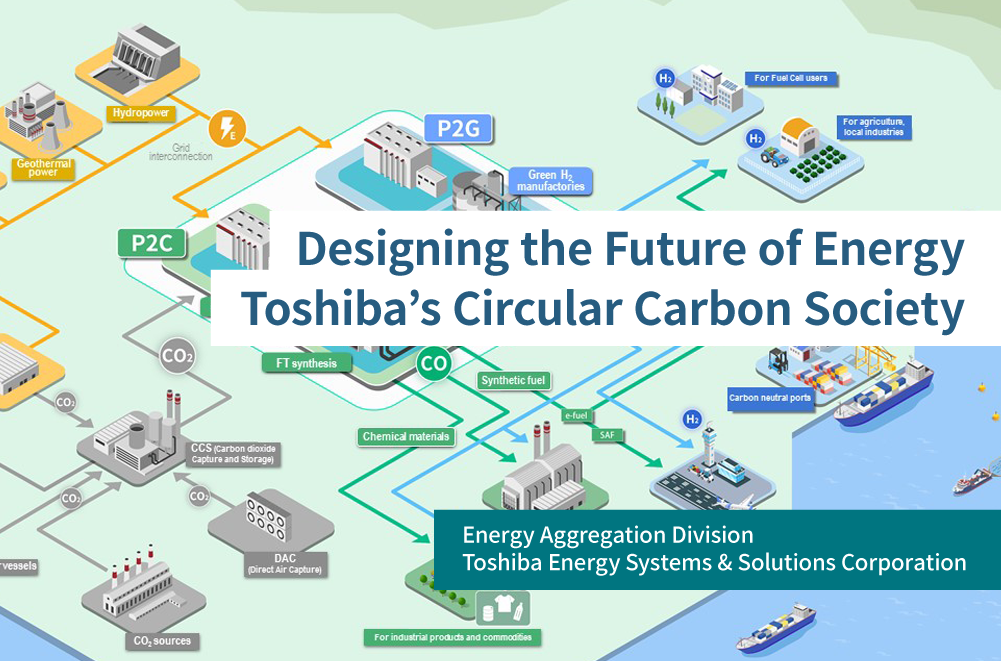

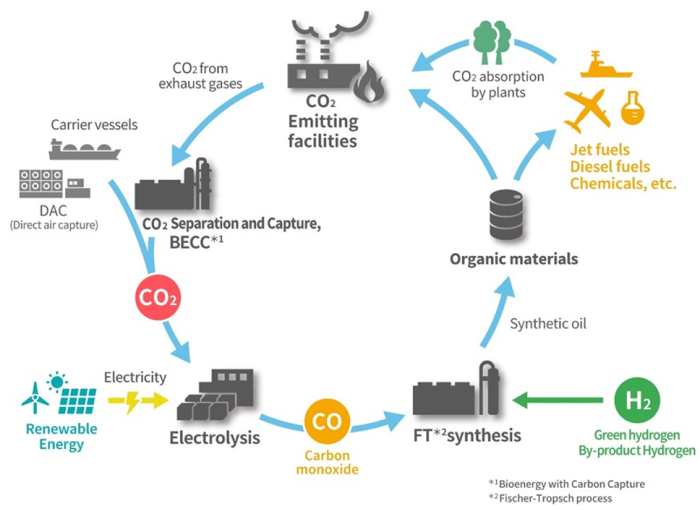

In simple terms, the aim of the project is to use renewable energy and electrolysis to convert CO₂ to carbon monoxide (CO), which can be used to make fuel or chemicals. The question is, how can sustainable business models that utilize CO₂ as a resource be implemented in society and create value? A key figure at Toshiba has one answer: “To see commercial flights using jet fuel derived from CO₂ by 2030…”

Making CO₂ a resource—the real value of carbon recycling technology

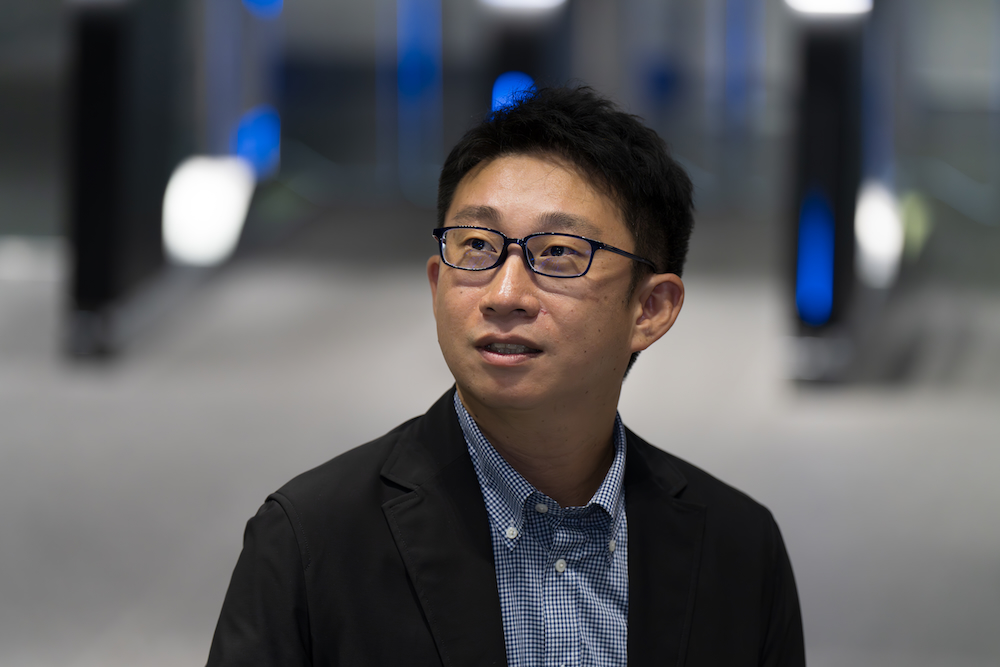

One goal of Toshiba’s research and business development is a carbon-recycling society, a world where CO₂ is recycled as a resource. P2C is one of the most promising avenues. Keita Nagano, the project leader, talks about collecting CO₂ from factories and other sources, and electrolyzing it to produce carbon monoxide (CO), a raw material that can be turned into fuel and clothing.

Toshiba Energy Systems & Solutions Corporation

“People all over the world are exploring many different ways to achieve carbon neutrality, such as using renewable energy as a main power source, improving energy efficiency, expanding the use of hydrogen, and splitting and storing CO₂. One of our initiatives is P2C with CO₂ electrolysis. Responding to climate change is an issue that affects all of humanity, and using P2C to reduce and make effective use of CO₂ is a way to kill two birds with one stone.”

Many industries are taking initiatives to cut CO₂. In aviation, the International Civil Aviation Organization (ICAO) has set targets for lower CO₂ emission reductions, and a key measure for this is sustainable aviation fuel (SAF) – jet fuel made not from fossil fuels but synthesized from biological and other raw materials. In all processes, from collection to production and combustion, SAF has low CO₂ emissions, and it’s safe to say that the future of the airline industry rests on the stable procurement and use of SAF.

Looking at this, Toshiba proposes an SAF supply chain based on carbon recycling, shown in the diagram below. The process extends from capturing the CO₂ to synthesizing SAF for use as jet fuel. Smooth operation throughout the chain would provide a stable supply of SAF, and also bring carbon recycling built around P2C into clearer view.

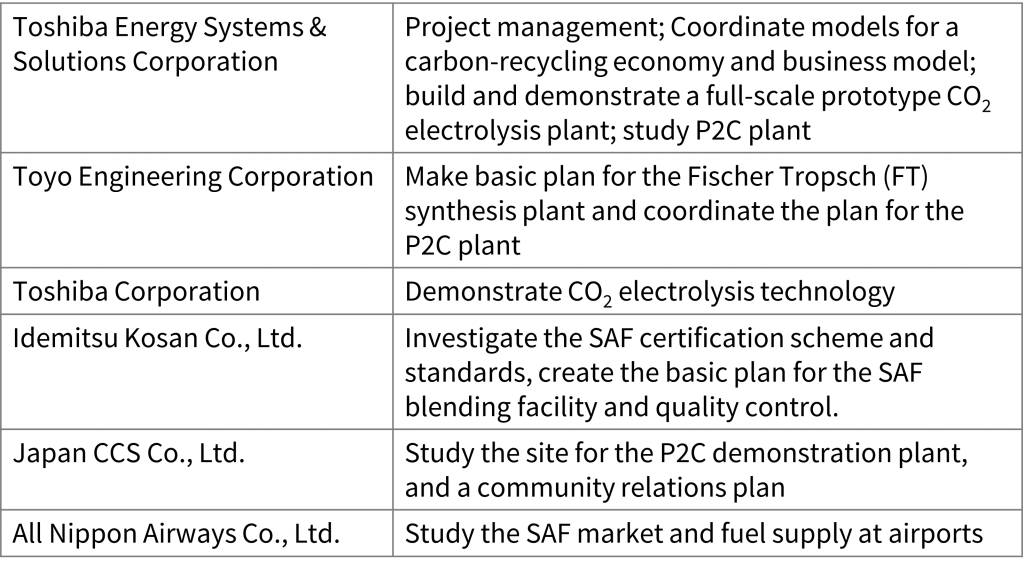

“Japan’s Ministry of the Environment has adopted this initiative,” says Nagano. “It has commissioned a project that brings together six companies, including Toshiba, and as part of that I am working on the strategy for its commercialization, domestically and internationally.

“There’s a lot to be done to bring it to fruition: coordinating with the participating companies, analyzing costs, discerning global technology trends… We are going to invest in a large-scale P2C plant, toward the ultimate goal of achieving carbon neutrality, and that will allow us to demonstrate the manufacturing capabilities Toshiba has cultivated. I find it very fulfilling to be involved in the project and to help move it forward.”

Moving global warming countermeasures one step forward through co-creation.

Prior to joining the P2C project, Nagano spent 10 years building and testing CO₂ separation and capture plants. That inspired his interest in P2C as a way forward to carbon neutrality, and led him to apply for a place on the project team. Throughout his time at Toshiba, he has consistently sought out challenging environments.

“At university, I was an electrochemistry major,” Nagano explains. “We used Toshiba equipment in the lab, and that introduced me to the company’s technological capabilities. Rather than academia, I was always more interested in working in manufacturing and business that made use of new technologies. That’s why I applied to work in the CO₂ separation and capture division in the first place.

“The deciding factors were that the work was related to carbon neutrality, and that it was a growing business. I wanted to work on something unprecedented, with no predetermined ‘textbook answers.’ Those were my original intentions and the starting point of my career.”

As he got deeper into CO₂ separation and capture, Nagano came to understand that “no project can ever be completed alone.” Learning about manufacturing techniques and building up industry knowledge was not enough to advance plant planning, construction, and management. And time and experience soon taught him that project managers already have a wide enough range of roles to fill as they estimate costs, negotiate contracts, and liaise with internal parties. It was unrealistic to aim for expertise in everything. With every passing day, he came to understand the importance of collaborating with colleagues and of sharing operational manuals, the knowledge accumulated by the team, and even the unique know-how of individuals.

“In business, time is of the essence. Being aware of that reminds me to that I don’t need to reinvent the wheel or look into what has already been researched and discovered. If you don’t know or don’t understand something, ask someone. You only start to investigate if asking doesn’t clear things up. Sharing knowhow and listening to each other solves issues and moves project forward, and it helps everyone to make efficient use of our most precious resource.

“That’s even more true for projects to counter global warming. That’s not something that any single company can accomplish alone. Using P2C to recycle carbon is something new, and it would be difficult for Toshiba alone to construct the required ecosystem. The six companies involved in our project are specialists in different fields, and we have to collaborate with each other in everything from CO₂ capture and electrolysis to synthesizing SAF and using it to fly planes.”

For a future where planes fly on fuel made with CO₂

Through the collaboration planes should be flying on jet fuel made with CO₂ by the 2030s. The aim co-creation is commercialization, a dream of a future that is now coming into view. Nagano says, “I want to be someone who brings together many stakeholders and leads the way forward.” To do that, it is necessary to attract companies who can contribute to solving issues and see business opportunities in P2C and SAF. Nagano elaborates on this, and becomes more impassioned as he shares his vision.

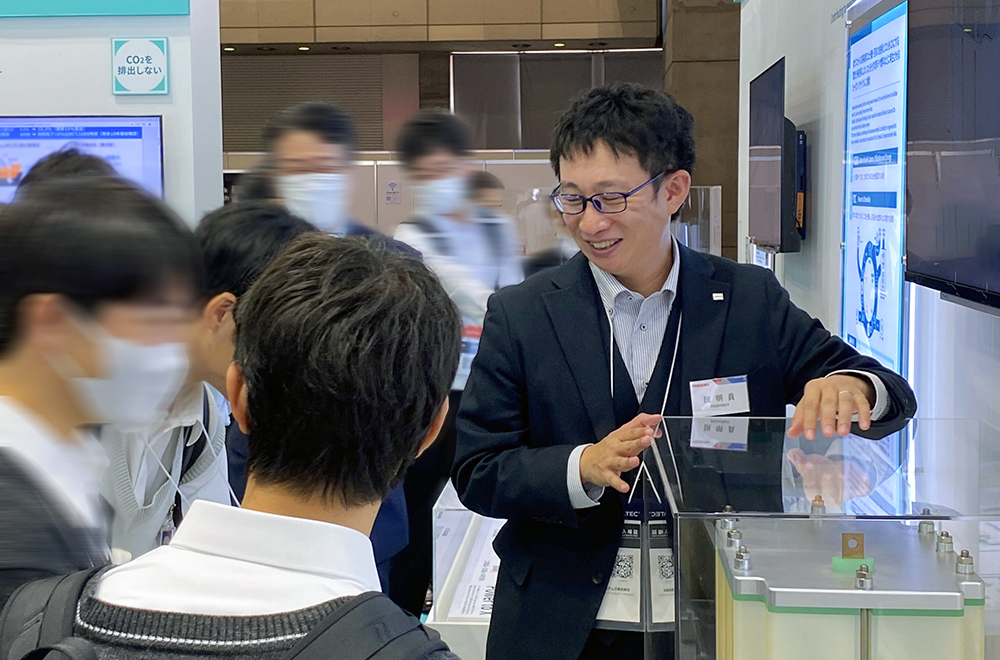

“Toshiba’s capabilities in P2C rest on technological foundations built up over many years. We have achieved world-class CO₂ processing speed, miniaturized the equipment, and cut costs. As we move toward commercialization, we are carefully considering how to balance durability, performance, and costs, and we continue to refine the technology in readiness for its implementation. If we want a sustainable decarbonized society, then the processes and business model that support the technology must also be sustainable.”

Nagano sees a future where converting CO₂ into a resource is a business that involves a lot of people, but he also hopes for a wider awareness.

“Things like abnormal weather mean that most people now have some sort of awareness of global warming, but I think it’s still difficult for us to see it as a personal matter, relevant to our daily lives. Even though economic losses from climate change are already enormous.

“The way I see it, this is something that humanity as a whole must take on, for the sake of the future of the global environment and our children… Ever since I joined Toshiba, I have wanted to create and carry out projects that solve problems society faces. I want my work to generate revenue for Toshiba and help to overcome those problems. Nothing could make me happier. Beyond that, I want to use the knowledge gained working on P2C development and implementation to create value in other new areas.”

The lessons he takes from the co-creation project will support Nagano in playing even larger roles in the future. He has colleagues both in Toshiba and the co-creation partners who share his vision. As a leader in the realization of P2C, Nagano’s eyes light up as he talks about his high hopes for the people who will join Toshiba in the future. How does he hope to improve his own performance, and what are his expectations of the younger generation?

“There’s a mountain of skills I am hungry to absorb, including consulting and how to put together projects structuring. I want to take on things that no-one else has done before. That has always been first and foremost for me.

“I also want to woke and interact with all kinds of people, and to train and develop the next generation. I want them to know that it is okay to fail as long as you take the initiative, and use that experience to create value for the next generation. That is Toshiba’s culture. I invite those who are not afraid to take on new challenges to join us in our efforts to solve the issues of the day.”

Related Links

*This section contains links to websites operated by companies and organizations other than Toshiba Corporation.

Hydrogen Energy | Toshiba Energy Systems & Solutions