Superconducting Technology can Pave the Way to a Carbon-Neutral Future and a Richer World.

2024/10/15 Toshiba Clip Team

- Superconductivity, the flow of electricity with zero resistance, is increasingly used in more and more fields.

- Toshiba has been advancing the application of superconductivity since the 1970s.

- The promise of a pivotal role in achieving carbon neutrality.

The captivating photograph above shows plasma glowing purple around a disk-shaped superconductor, free from all electrical resistance and floating in vacuum, supported by electromagnetic force.

Superconducting technology is no stranger to the pages of Toshiba Clip. In earlier articles we have covered its contributions to heavy-ion therapy systems that treat cancers, the coils of the emission-free ITER fusion reactor, and a prototype electric motor for powering aircraft. Today, we take a wider look at what exactly superconductivity is, challenges overcome in its development, and its commercialization. It’s a technology Toshiba has worked on since the 1970s, and we talk to two engineers engaged in technological development and product design. They are our guides to superconductivity’s past and present, and the contributions it will make to a carbon-neutral future.

Superconductivity has the potential to revolutionize everything from healthcare to transportation

We’ve all seen the science programs that explain superconductivity: position a magnet near enough to a superconducting material cooled to close to -273°C and, as if by magic, the magnet floats in midair, above the superconductor. The discovery of this phenomenon, by Dutch physicist Heike Kamerlingh Onnes in 1911, triggered further investigation and a search for real-world investigations that continue to this day, and that saw a rapid acceleration in the 1970s. We asked Tsutomu Kurusu, a superconductivity engineer at Toshiba Energy Systems & Solutions, why leading manufacturers invest in this R&D, and about the potential of the technology.

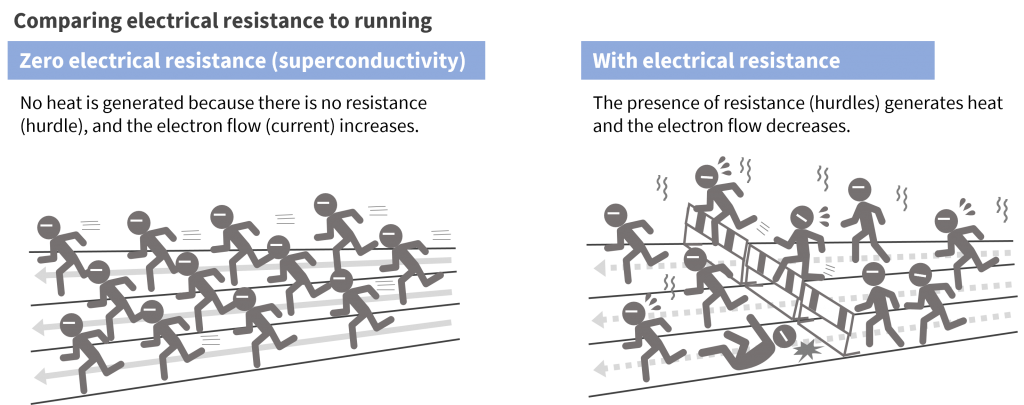

“As you know, when an electric current passes through a conductor its meets resistance, caused by its electrons colliding with the atoms of the conductor. This generates heat and power is lost. However, if you cool some metals and compounds to extremely low temperatures, this resistance disappears. If you use a superconductor in a power line, you get lossless transmission of electricity.”

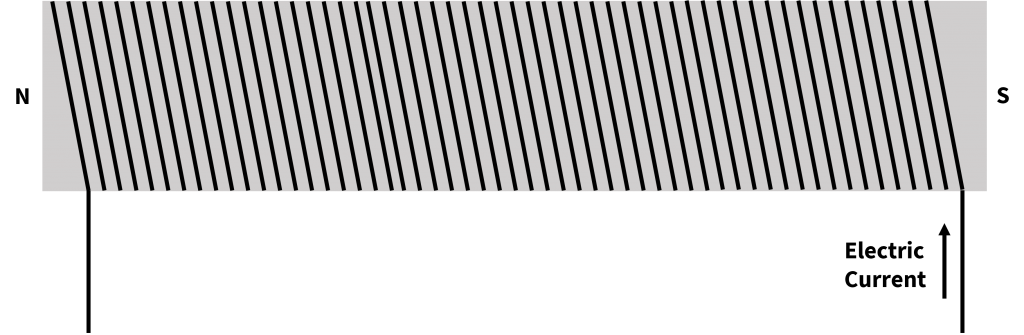

When superconducting materials are formed into wires and wound into coils, they can be used to create superconducting electromagnets that generate extremely strong magnetic fields over large areas. This is impossible with permanent magnets or electromagnets made from copper wire, and the reason why there is a lot of interest in superconducting magnets in fields as different as medical care, transportation, and manufacturing.

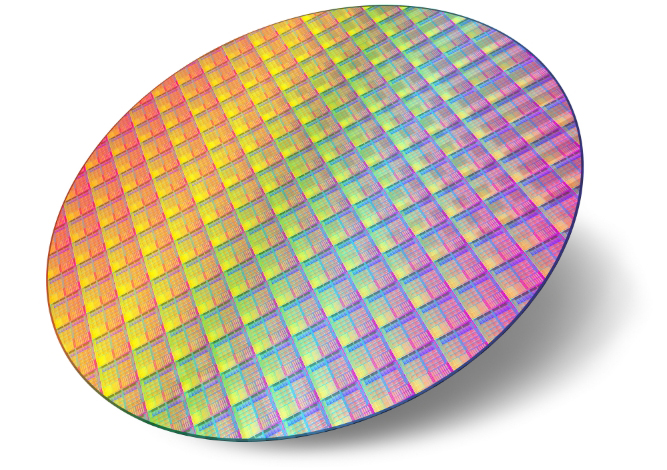

“Permanent magnets generate a magnetic force of about 2 tesla near their poles,” explains Kurusu. “For superconducting magnets, the figure is above 40 tesla, and over a wider area. This characteristic is why superconducting magnets are used in magnetic resonance imaging (MRI) for diagnostic imaging of the body, heavy-ion therapy equipment, ITER’s experiment fusion reactor*, and the Large Hadron Collider at CERN, which found the Higgs boson particle. Strong magnetic fields are essential in many areas. Closer to home, superconducting magnets also play important roles in manufacturing. There’s a good chance that they helped to make the silicon wafers for the semiconductors in the electronic products you use.”

* A major international project to build the world’s first experimental nuclear fusion reactor.

Semiconductors are etched onto highly pure silicon wafers that are sliced from large, monocrystalline silicon ingots. In the process of forming the ingots, superconducting magnets control convection and the temperature gradient in the crystal, improving the quality of the ingot and the wafers that are cut from it. Applying superconductivity will realize much more efficient energy transmission, and other applications extend into fields that include medicine and transportation. It’s a technology with immense promise, and there’s a lot of anticipation about its broader application and the benefits it will bring.

Manufacturing strengths that set Toshiba apart in the development of superconducting equipment

R&D in superconductivity is a global effort that is driving the development of useful products. One of the most important research concerns is maintaining a balanced, stable superconducting state. But the fact is, superconductivity can be a double-edged sword, because a strong electromagnetic force can cause superconducting coils to stop functioning. Tsutomu Shimonosono of Toshiba, who works on the commercialization of superconducting technology, is well aware of this: “Many times during the development process, we found we couldn’t control the electromagnetic force, and ended up with damaged superconducting magnets. We thought constantly about how to maintain coil functionality and ensure products were stable over the long term.” Key to achieving this was the wealth of expertise Toshiba has built up over many years of manufacturing energy equipment.

“I work at Keihin Product Operations,” explains Shimonosono. “We have developed and manufactured energy equipment for nearly 100 years, and have a track record of working on coils for large generators and motors that dates back to long before development of superconducting magnets. We looked at a lot of ideas for solving the stability problem, including encapsulating coils in resin so they function under strong electromagnetic forces. That’s where expertise in generators and similar equipment came into play. We worked with the generator division, using their cumulative know-how to complement and advance our technology. These achievements in superconductivity development stem from Toshiba’s singular capabilities.”

Cooling is essential for achieving a superconducting state. Not just to a low temperature, but maintaining the extremely low temperatures of 4.2 Kelvin, -269°C; just a few degrees above absolute zero, -273.15°C. Toshiba has consistently advanced capabilities in this essential area.

“I think that the containers we designed to house the coils of superconducting magnets show our capabilities,” says Shimonosono. “They have to be filled with the coolant, liquid helium, and to prevent its evaporation we developed a multi-layered vacuum insulation container, similar to a thermos to look at. We’ve also developed a method for direct cooling that can bring a superconducting magnet down to 4K without using liquid helium. This conserves helium as a resource, and also improves safety.”

The ability to refine cooling techniques by integrating know-how from entirely different fields underlines the breadth of Toshiba’s technological expertise. The company is also enhancing its coil winding technology to meet demands from factory operations, and in this case it’s established strengths in developing manufacturing equipment and production jigs that has come into play.

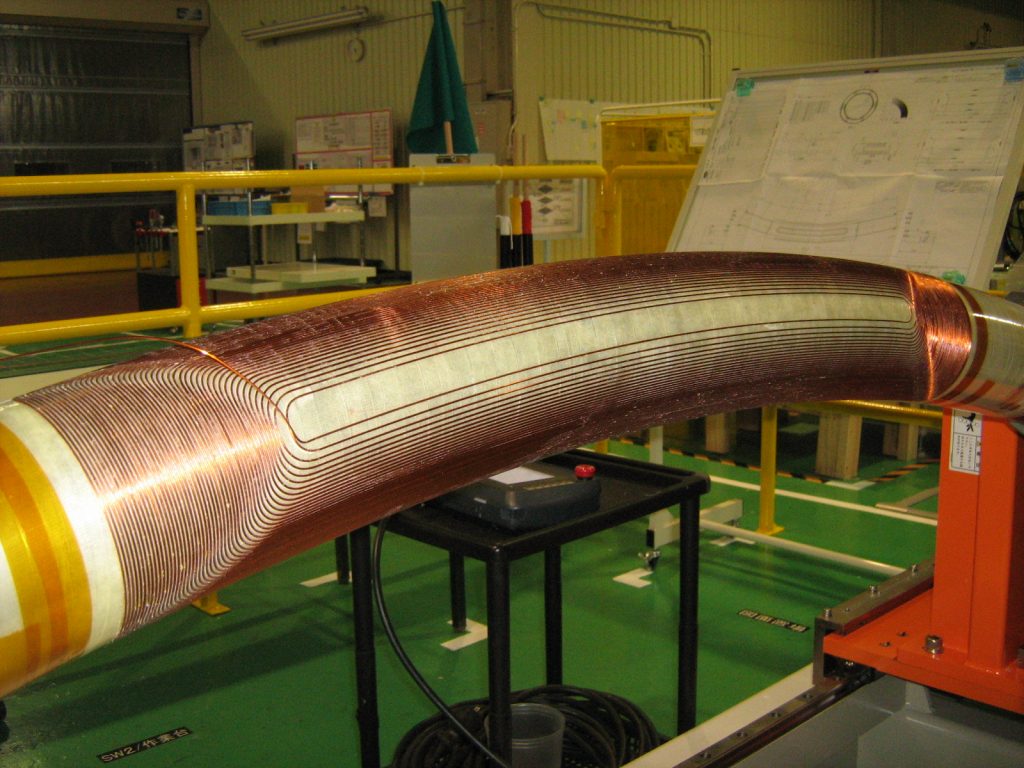

“We’ve honed our technology for optimizing magnetic fields and maximized efficiency at the same time,” says Shimonosono. “We computerized control of the winding machines, and now we can produce coils with a shape optimized for the magnetic field distribution our customers want. This also allows us to generate magnetic fields of the same strength but with fewer materials, which reduces manufacturing costs.

“Coils designed for complex magnetic fields, so-called 3D(dimension) coils, were initially developed at the request of one of Japan’s national research centers. You cannot use force to bend or reshape coils once they are wound, they just won’t meet specifications, so we collaborated with our Corporate Manufacturing Engineering Center to establish a manufacturing technique that involves stiffening coils with an adhesive during winding. By leveraging Toshiba’s comprehensive capabilities, we introduced technologies that met high-level scientific research requirements.”

Superconductivity and carbon neutrality

While superconductivity is being increasingly deployed, and there’s still a lot of room for growth. “Technology Strategy Report (2015),” published by the New Energy and Industrial Technology Development Organization, a Japanese government agency, forecasts a global market for superconducting devices exceeding 1.5 trillion yen, approximately US$10 billion, by 2030. Areas of anticipated demand included high speed maglev trains, motors for next-generation aircraft, power transmission cables, superconducting magnetic energy storage, fusion power generation, and MRI and heavy-ion therapy. Superconducting technology is set to enrich the world and bring us new levels of convenience.

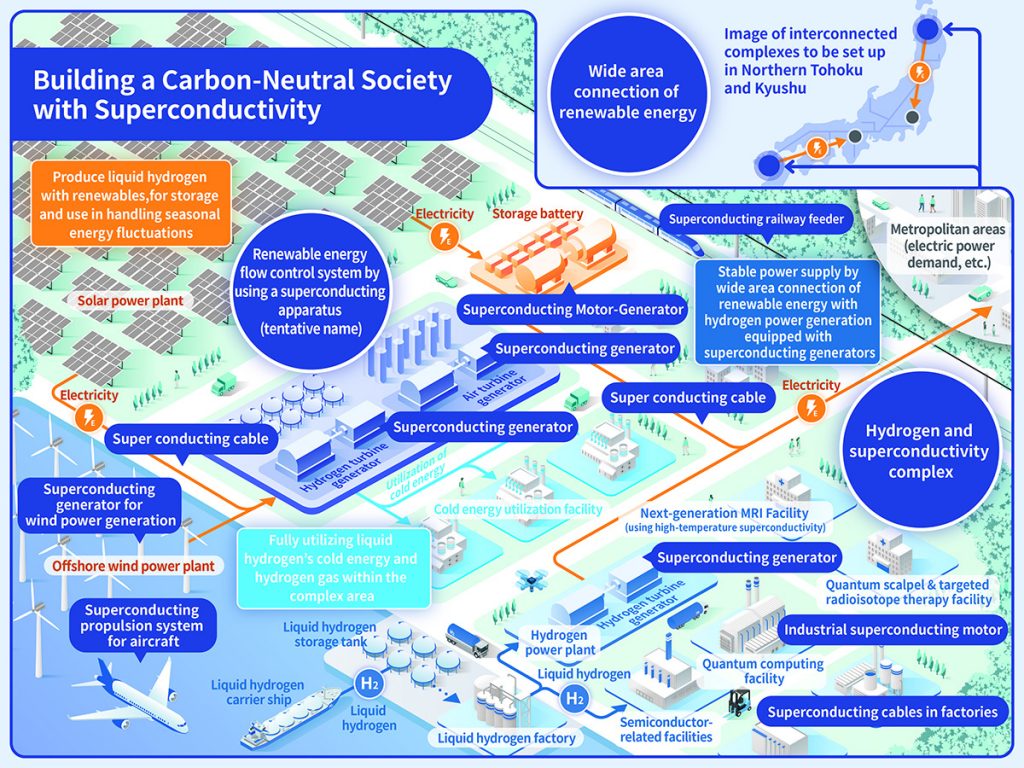

Looked at from a broader perspective, superconducting technology could even serve as the foundation for a carbon-neutral society, due to its high degree of compatibility with hydrogen energy and renewable energy sources. We asked Kurusu about this.

“Japan plans to achieve carbon neutrality by using hydrogen as a new energy source,” he explained. “The questions is, where do you get the hydrogen? Current plans call for importing it from overseas, and the way to do that is as liquid hydrogen. Now, liquid hydrogen boils and vaporizes at 20.4K, so it must be transported at an extremely low temperature of 20K. This is a scenario where superconductivity can help to provide answers.

The overall vision for effectively harnessing liquid hydrogen toward achieving carbon neutrality is the Hydrogen and Superconductivity Complex, promoted by the Council on Competitiveness Nippon. It’s currently involved in multilateral discussions that aim to turn that vision into reality.”

“By 2050, we expect to achieve carbon neutrality. Hope lies in technologies that minimize power loss and are environmentally friendly. As we continue to search for ways to reduce greenhouse gases nationwide, various initiatives are being pursued to ensure superconductivity makes a crucial contribution,” says Kurusu.

The properties and potential of superconductivity position the technology to have a profound impact on the realization of a sustainable economy. Fully aware of this through their work at a company that has been deeply involved with superconductivity since it first came to Japan, Kurusu and Shimonosono are cultivating a vision of how to use and deploy superconductivity, and to integrate it smoothly into real-world applications.

“Toshiba has been working on superconductivity for over 50 years,” says Kurusu. “Applying it to achieving carbon neutrality is a long-term endeavor. But this is a company that has grown sustainably and reinforced its technological foundations as it has progressed. I am certain we can successfully leverage our strengths in superconductivity.”

Shimonosono is also confident: “Superconducting materials have enormous potential, and we plan to bring products to market that take full advantage of that. Our track record shows we are the only company with the confidence to take on and meet any request that comes our way—we take pride in that. As a leading enterprise, we will continue to conduct research and development that we can pass on to the next generation.“

Related Links

*This section contains links to websites operated by companies and organizations other than Toshiba Corporation.

Energy Systems Research and Development Center | Toshiba Energy Systems & Solutions