Toshiba’s Lithium-Ion Batteries – driving the future of a decarbonized society (Part 3)

2021/03/17 Toshiba Clip Team

- The SCiB™ rechargeable battery is evolving to reach even greater performance.

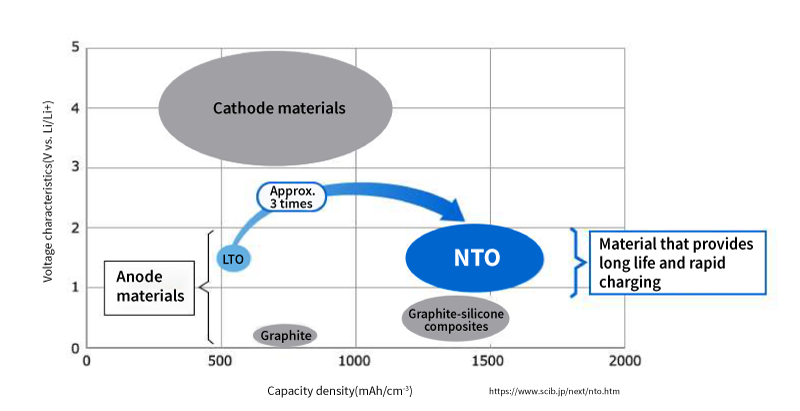

- Niobium titanium oxide (NTO) is a next-generation anode material that will exceed lithium titanium oxide (LTO).

- Electrospinning technologies will create an ultra-thin next-generation separator membrane.

The entire world is talking about the future potential of lithium-ion batteries. In Part 1 and 2 of this series, we looked at new developments in the field and the Toshiba’s SCiB™ rechargeable battery, which paves a path to the future by using lithium titanium oxide (LTO) in its anode. SCiB™ resolves the difficulties faced by conventional lithium-ion batteries and is starting to be used in a wide range of fields, from automobile to social infrastructure. In this third and final segment of the series, we’ll look at how Toshiba’s newest technologies will develop SCiB™ even further.

Toshiba’s Aspirations: Next-Generation Technologies to turn on the promise of a new day

SCiB™ overcame the hurdles faced by conventional lithium-ion batteries by increasing safety and life expectancy. But it’s still evolving. Toshiba is currently developing new cell models, the 20Ah-HP and 4.8Ah-HP, which combine the performances of the two existing types of batteries: the high-energy type and the high-power type. Our researchers kept the basic structure of the battery in place and tuned the parameters of the electrode, separator and electrolyte. As a result, they succeeded in creating a “perfect blend” of both the energy density of the high-energy type and the power density of the high-power type. Since the input/output performance has been improved while maintaining the same size as current cells, it is possible to upgrade existing modules and packs by using the same design. For example, in the automotive industry in recent years, hybrid cars are required to apply higher performance in order to comply with emission regulations mainly in the European market, and the 20Ah-HP and 4.8Ah-HP are batteries that are suitable for such applications that require high energy density and high input/output.

The SCiB™ battery’s evolution has also reached a point of re-examining its core identity—the anode material. Toshiba is focused on working with niobium titanium oxide (NTO) as the next-generation anode material for its outstanding characteristics. NTO has roughly three times higher theoretical volumetric capacity than LTO, while providing the advantages of LTO – such as long life and rapid charging. Our researchers are aiming to combine these NTO characteristics with Toshiba’s unique electrode technologies to raise the battery’s volumetric energy density by 1.5 times while keeping its long life and rapid charging performances. In recent years, robots designed for interaction with humans are becoming increasingly common in our society. With NTO, mobility vehicles powered by SCiB™ will be able to become smaller, more lightweight and travel longer distances, leading to the creation of new social value.

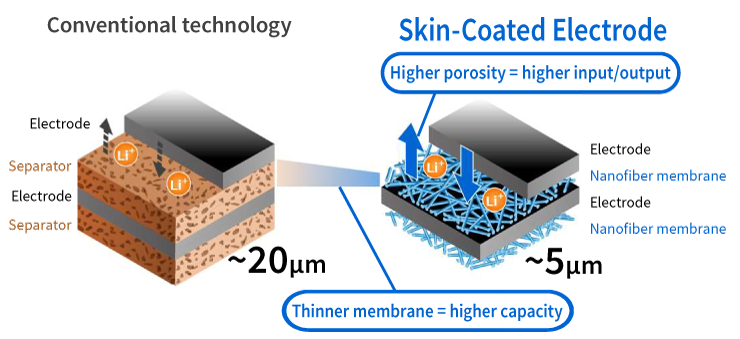

Next-Generation Separator: Ultra-Thin 5 μm Skin-coated electrode Membrane

In addition to NTO, one other new technology will propel SCiB™ to new heights: the skin-coated electrode, which is a next-generation separator to divide the cathode and anode. The skin-coated electrode is a completely new structure that coats the surface of the electrode materials with an ultra-thin resin nanofiber membrane. In conventional structures, the separator is an independent membrane, around 20 μm thick, that provides electrical insulation between the cathode and anode. But, Toshiba succeeded in developing an original ultra-thin separator that is integrated with the electrode and only around 5 μm thick.

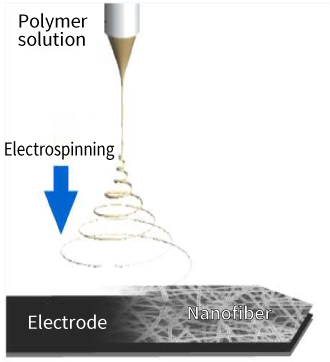

To form the membrane, Toshiba uses a technology called electrospinning, which is a method of producing nanofibers. This is done by applying high voltage to a polymer solution to spin yarn. Electrospinning creates an ultra-thin membrane that acts as a separator with excellent electrical insulation and heat resistance. Being able to bring the electrodes as close as possible to each other enhances energy capacity and input/output performance. Furthermore, increasing the membrane’s porosity also increases ion conductivity and reduces internal electrical resistance, which enhances the input/output performance even more. Compared to conventional separators, the nanofiber membrane also has the advantage of being able to cut battery insulator-related costs by roughly a half.

Through the three articles in this series, we introduced Toshiba’s next-generation SCiB™ battery as a solution to the world’s expectations for new developments in the field of lithium-ion batteries. SCiB™ has various outstanding characteristics, including safety, long life and rapid charging, which contribute to worldwide efforts to address global warming. For example, the battery helps industries in various fields reduce carbon emissions through automation, reduce operating costs to boost economic growth, and improve public trust by building emergency systems. Such improvements will add greater value to sustainable urban development and many other social infrastructures. The evolution continues. Our path forward will always be under the banner of the Basic Commitment of the Toshiba Group: Committed to People, Committed to the Future.

![]()