Toshiba’s young engineers: Drawing on the spirit of kyudo to improve reliability

2021/04/14 Toshiba Clip Team

- Molding technology essential for improved semiconductor reliability

- Three people working together as one to overcome difficult problems

- Guided by the spirit of enquiry and the spirit of kyudo, Japanese archery

In 2020, the coronavirus has pushed us into a paradigm shift that is bringing dramatic changes to the world. But there are people who are not just idly standing by and watching this, who know that it’s not only the virus that can change the future—that there is always a future that can be shaped by human hands. Toshiba has many young engineers who will create and live in that future, and in this series we introduce some of them.

Beyond generations, strengths are woven by the minds that face technology

Members of Toshiba Group’s kyudo club in and around Tokyo have long practiced their Japanese archery skills at the kyudo dojo in Toshiba’s Komukai Complex in Kawasaki, Kanagawa Prefecture. Yoshiko Takahashi has numbered among them for a few years now, since joining Toshiba in 2016. She first picked up a kyudo bow 13 years ago, as a high school student, and today represents Toshiba in corporate competitions.

Yoshiko Takahashi, a member of the Package Solution Technology Development Department,

Electronic Devices & Storage Research & Development Center, Toshiba Electronic Devices & Storage Corporation

“I didn’t expect to continue kyudo after starting work. I found out about the kyudo club after I joined the company, and it came as a bit of a surprise.” Ms. Takahashi speaks with a carefree smile, and goes on to mention another side of herself, as a developer of semiconductor manufacturing technology: “Our group develops technology for the molding process that encloses semiconductors in resin.”

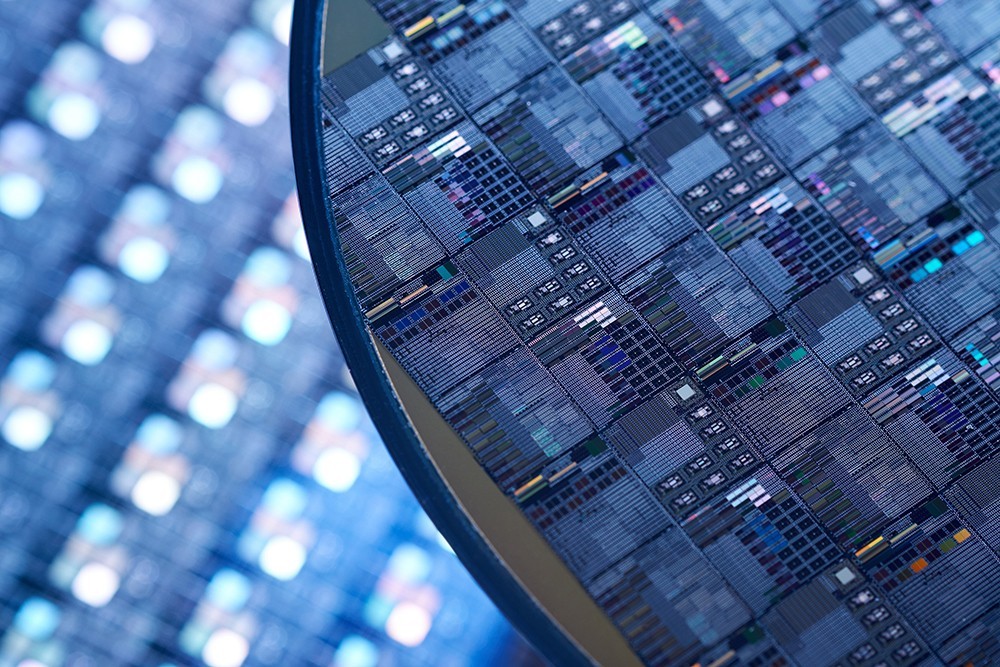

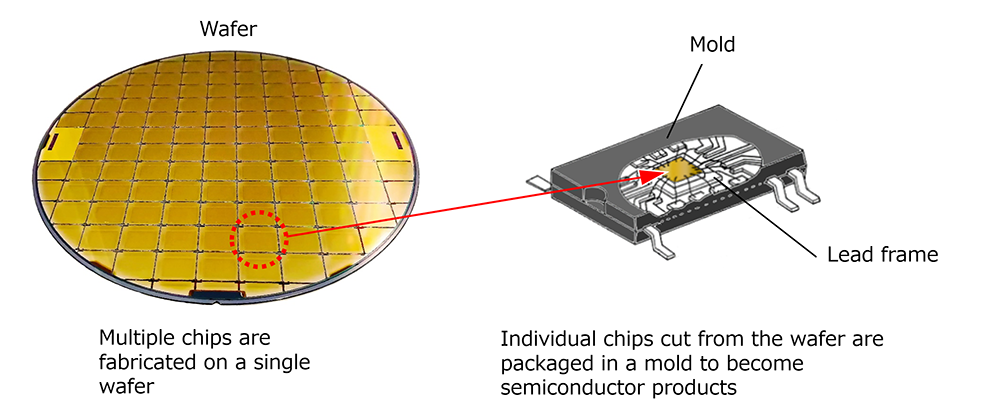

Mention semiconductors, and a lot of people will picture arrays of wire-shaped electrodes that seem to be sprouting from blackish resin. However, the main body of the semiconductor is the small, thin chip housed in the resin package.

The chip, the main part of the semiconductor, is packaged in a resin mold.

“The large majority of semiconductors are manufactured by mounting the chip on a metal lead frame and then encasing it in a resin package. Protecting chips from external heat, shock, and moisture with the molded resin is an important factor in determining the reliability and durability of semiconductors. “

Semiconductors can be found in everything from TVs and home appliances to automobiles and industrial equipment. In the automotive market, they are playing a crucial role in the growing popularity of electric vehicles and the improvement of autonomous driving technology. Just as vehicles are entrusted with people’s lives, semiconductors must be manufactured with a reliability that allows us to entrust them with people’s lives.

“Semiconductors are indeed small,” says Ms. Takahashi, “but improving their reliability is a big mission.”

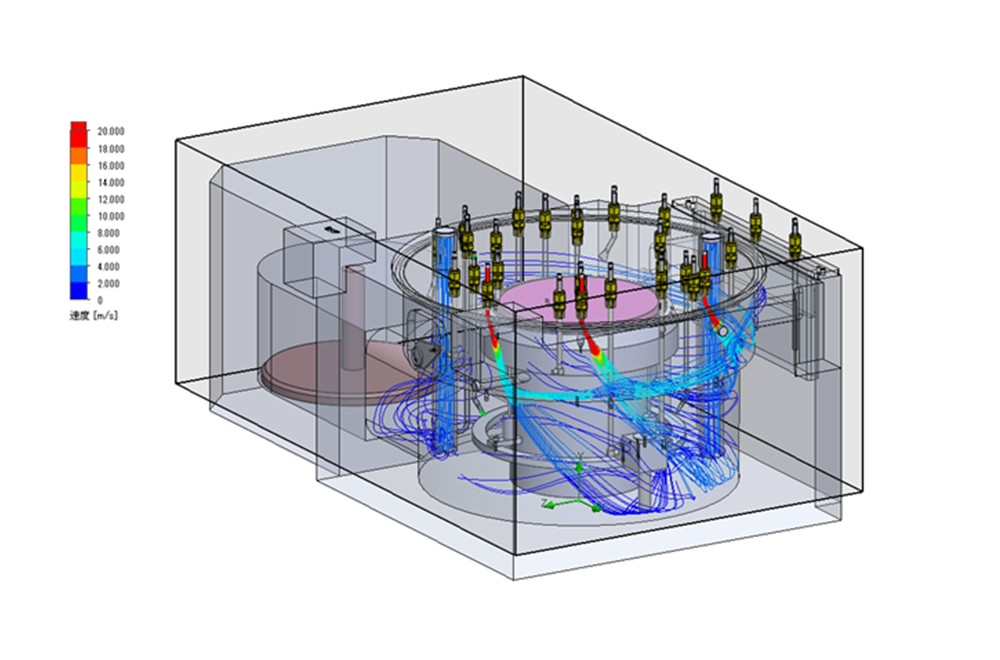

The resin and lead frame that, along with the chip, make up a semiconductor have different physical and chemical properties, and they can deteriorate as a result of temperature changes. Factors like the forces generated by constant expansion and contraction can cause the materials to break down, to the point where they no longer provide the chip with proper protection. The goal of Ms. Takahashi’s group is to improve the reliability and durability of semiconductors by realizing a molding process that can handle all kinds of environmental changes over the long term.

Ms. Takahashi is one of a 3-person group working on development of molding process technology.

At first glance, a couple of young employees with their boss that can be found anywhere,

but Ms. Takahashi says that the relationship between the three is a little different.

“Our leader is Masahiko Yajima, and I certainly respect him as a senior engineer and as my boss, but we are also close enough as a group that he, my colleague Yuning Tsai and I, always have lunch together.” Because it is a relationship that transcends generational boundaries, all three agree that it is easy to express their opinions and ask questions.

“We had a problem with one of the machines we use for experiments in the molding process. Even though I was using it correctly, it stopped repeatedly, and nobody knew why. We were able to get to the bottom of the problem thanks to the three of us being able to share ideas and opinions on all sorts of possibilities.”

The cause of the failure turned out to be a malfunction in a sensor that detected when the machine’s door was open. But suspicion first fell on operation error, and that was followed by a review of all the settings.

“It was a steady task of eliminating possibilities one by one, and the three of us encouraged each other to press on and find the source of the problem. If I’d had to do all myself, I might well have given up.”

Ms. Takahashi with the testing machine

It turned out that the cause of sensor malfunction was not a machine failure, a wrong setting or misuse, but the way it was installed in the first place. Ms. Takahashi is convinced that the discovery of such an unlikely cause is all due the cooperation of all three of them.

“Currently, we are trying to improve reliability by increasing the adhesion between the lead frame and the mold resin. The results of our experiments can turn out as expected, but there are often times when the result is a little off. Even if that happens, the team can readily discuss the results, and then we can put together each other’s opinions and quickly move on to the next action. We are moving forward every day, aiming for application in our mass-production products.”

Ms. Takahashi says that the team’s mutual respect for each other allows the three of them to reach opinions as one, allowing research to proceed smoothly. This is clearly a group where Toshiba Group’s philosophy of “creating together” is alive and well.

Staying honest is the key to improving reliability

At university, Ms. Takahashi majored in applied chemical engineering, and her studies included fuel cells. Toshiba attracted her interest because she wanted to develop things that were tied to the end products.

“In school, my friends and I compared materials from many companies. I got the impression that Toshiba has a lot of holidays, and had a well-developed welfare program and flextime system, but above everything else I was attracted by a company I’d known the name of ever since I was a kid.”

She attended a recruitment briefing session, and that event led her to choose Toshiba.

“There were a lot of students at the Toshiba briefing, and because I’m very short, even if I turned toward the voice of the speaker, I couldn’t see anything! Then, the moderator in charge of the proceedings said, “Some people may find it difficult to see, so please work out where you should be so that everybody has a chance to see.” Naturally enough, in response to this announcement the recruiters at the venue guided a short person like me to the front row. ”

Ms. Takahashi says this was not “preferential treatment because I was a woman,” and that is made a lot of sense to position taller people at the back and shorter people at the front. She still remembers being impressed by this smoothly handled guidance.

“I remember thinking at the time, ‘I’m sure this is a good company for both men and women.’”

However, when she decided to join Toshiba, and started to imagine her future at work, the fraudulent accounting problem suddenly erupted. Naturally, both she and the people around her were worried about her future.

“At that time, a Toshiba recruiter said to me, ‘You are an engineer, and what an engineer does doesn’t change.’” Ms. Takahashi still follows these words as the foundations of her work as an engineer.

Experiment as many times as necessary, until you get clear results, says Ms. Takahashi

“There are times when experimental data is not clear. It can be interpreted as either good or bad, and sometimes when that happens, against my better judgment, I try to come up with a story that sounds right to me. That’s when I recall the words of the recruiter, ‘What an engineer does doesn’t change.’”

She explains that what that means is to continue to experiment and to try out new approaches until the results are clear. This is precisely the value of “Do the right thing” in the Essence of Toshiba.

“I don’t want to do anything inappropriate with technology. My senior colleagues have taught me that the only way to earn trust is to continue to work in good faith, and to not give up until you can make something that is really good. So, little by little, I too try to make good things, aiming for the time when I realize that I did something and it was really good…”

In kyudo, there is a saying, “shoot right, hit the target.” What this means is that an arrow that is released correctly, with the proper posture and form, always hits the target. Ms. Takahashi’s determination to get to the right technical answer can be seen as embodying the spirit of this approach.

Ms. Takahashi looked back on four years in Toshiba and offered the following comment.

“Toshiba Group has all kinds of technology, so, even if you don’t understand something yourself, there’s someone in the Group who can tell you. I’m very aware of that depth. In a few years’ time, I want to be in a position where I am seen as somebody who can be relied on. That’s what I want.”

![]()