Arm in Arm: Toshiba’s New Robot and Coexistence with People

2018/04/02 Toshiba Clip Team

We increasingly take robots for granted. Robots on production lines are an old story, and for shoppers in Japan their synthesized greetings are no longer a novelty. Robots are here, all around us, and definitely here to stay. In fact, in many ways, they’ve only just arrived.

Go back to the robot receptionist. That’s something new. Only few years ago, they did not exist. Robots were more about heavy lifting and moving while people… Well, people stood clear. But we’ve now reached an inflection point, where technology and AI are taking robotics to new levels and into new places, including our shops, hospitals, schools and homes.

From now on, robots are and will be everywhere—and that raises a lot of questions about how robots and people coexist. It’s something that’s long interested Hiromasa Takahashi, chief specialist at Toshiba’s Corporate Manufacturing Engineering Center. As a boy, he was enthralled by the high tech futures explored by science fiction, and as a man he is trying to harness those technologies, and to contribute to society.

“Today’s robots generally perform routine tasks based on pre-programmed protocols. That will change though,” observes Takahashi. “AI technology will give machines stronger cognitive faculties, and I have no doubt that robots will become able to conduct non-routine work. When they do that, they must work alongside humans, and people must be comfortable doing that.”

Hiromasa Takahashi chats about robots and people

With that in mind, Takahashi and his colleagues set out to create a robot that could coexist with humans in the demanding environment of the workplace. In doing so, they set themselves a series of challenges.。

So far, robots have found their niche in mass production lines, doing repetitive tasks. They have yet to find a place in high-mix, low-volume lines, increasingly recognized as the future of manufacturing. That provided one goal. After that, they turned to Japan’s demographics. An aging population points to diminishing competitiveness, but also provides an incentive to use robots—robots that can work with people as part of a team. Then there was the robot itself, its size, appearance and capabilities.。

Compactness, Strength, and Coexistence with People

As a rule of thumb, the bigger the load capacity it can handle, the bigger the robot; boost the load, and you get a bigger machine—one that not only impacts on the space efficiency of the production line but also tends to intimidate people. The truth is people can be fascinated by the form and movement of robots, but very uncomfortable working alongside them. Takahashi wanted to build a robot that can not only lend a hand, so to speak, but that’s also non-threatening to the people it assists.

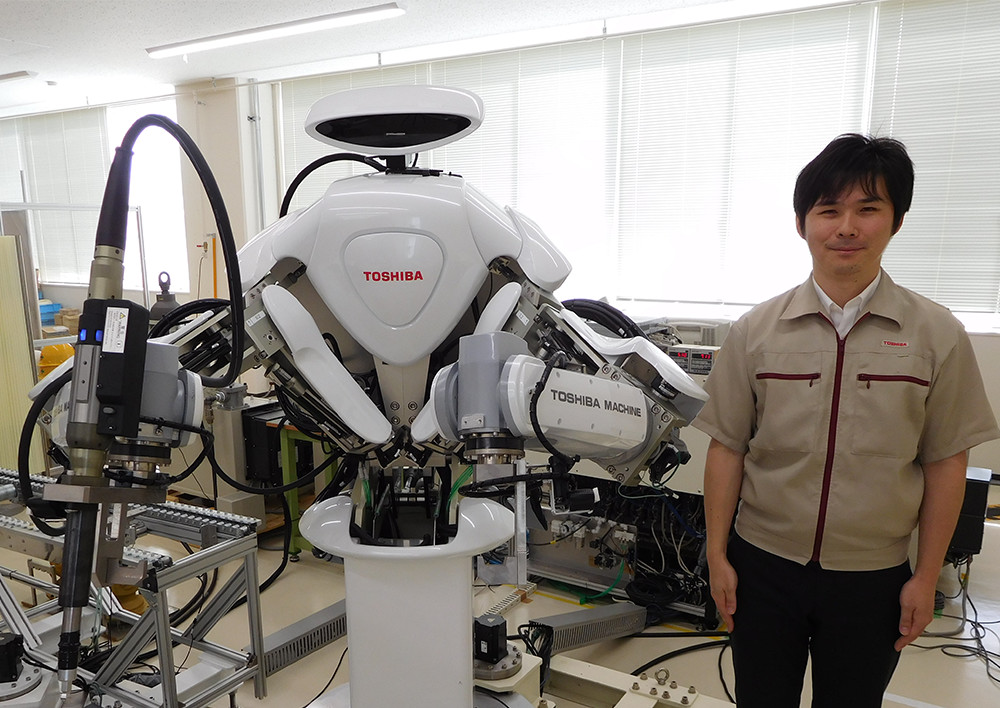

As he explains, “We wanted to create a robot that people could feel comfortable to be with, something that they could trust, so we focused on three core design concepts: gentle, smooth contours; eye-pleasing colors; and dynamic detail.” That’s all clear at first glance. The robot is finished in white plastic molded into curves and rounded planes. The insignia on its chest, set off with a calming blue LED during operation, is friendly, even a bit super-heroish. The way the “head” moves is also familiar and humanlike.

The prototype embodies the three design concepts

At this point, the robot is still a work in progress—but the progress is pretty impressive. It’s the big guy on the line, getting on for 2-meters tall, but even with two arms, the robot is only 70cm across the “shoulders”, and has the same size requirement as a living, breathing person. That will allow the robot to slot into existing lines with no need to overhaul layouts.

Of course, the ultimate test of any machine is how well it works. What about Takahashi’s robot? He immediately returns to the issue of size. “Japanese law sets 20kg as the maximum load for any line worker, and the conventional approach is to use electronic robots that operate within that framework. They achieve good control and accuracy, but they are not good for heavy loads—for that you need cranes and other equipment.

“We wanted to increase the load and add lifting power to our robot, which made us think of hydraulic actuators. As they can’t deliver the response accuracy we also wanted, we experimented until we found the right combination of electric and hydraulic elements. With that, we realized precise performance with a maximum two-arm load of 100 kg.”

The robot shows its skills in a February 2017 video

It’s an impressive achievement, one that Takahashi attributes to Toshiba Group’s wide-ranging array of technologies. That foundation will also support the development team in achieving its next goals: upgrading the dual-arm robot’s functionality, launching mass production, and cultivating a market.

Takahashi is excited about the prospects. “Industry has never seen a robot compact enough to team with human workers on production lines and capable of lifting 100-kg loads. Our robot embodies a seed-oriented strategy—an effort to propose and nurture value for the future. There’s still work to do, we have to make the hydraulic pump smaller, for example. But soon enough, people and robots working together will be a reality. I’m happy to contribute to that.”

Takahashi and his creation pose together

![]()